Chemical mechanical polishing of copper-oxide damascene structures

A technology of chemical machinery and polishing slurry, which is applied in the direction of grinding/polishing equipment, grinding machine tools, and parts of grinding machine tools, etc. It can solve the basic principles of geometry and material properties, unclear friction mechanism, depression, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

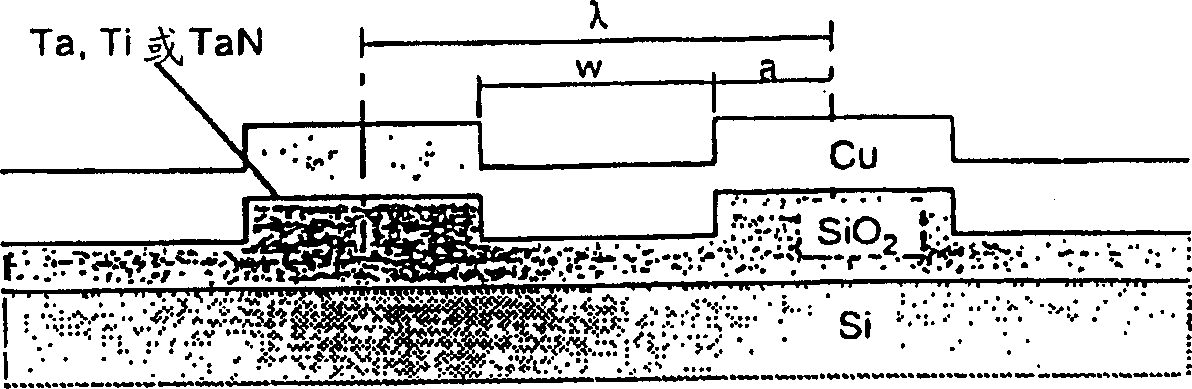

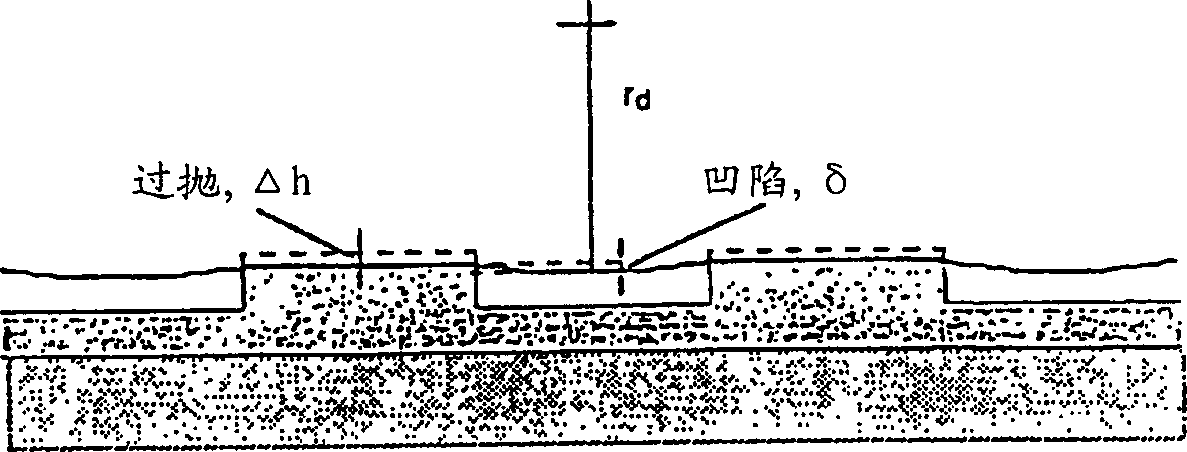

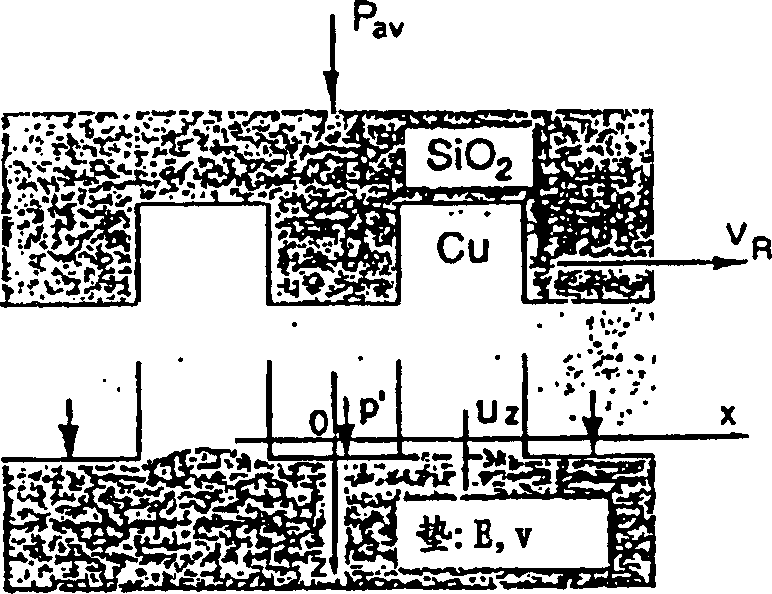

[0052] In all descriptions of the present invention, the following symbolic terms are used, and these terms are defined as follows:

[0053] A f = area fraction of metal pattern

[0054] a = half of the line width of the metal pattern (m)

[0055] C 1 、C 2 、C 3 = integral constant

[0056] E = Young's modulus of cladding material (N / m 2 )

[0057] f n , F = normal force and tangential force on the wafer (N)

[0058] H = Hardness of cladding material (N / m 2 )

[0059] H' = apparent hardness of composite surface (N / m 2 )

[0060] h = thickness of material removed from wafer surface (m)

[0061] k n = Preston constant (m 2 / N)

[0062] k w = wear coefficient

[0063] P = load per unit length on high parts (N / m)

[0064] p = normal pulling force on the wafer surface (N / m 2 )

[0065] p av = Nominal pressure on wafer (N / m 2 )

[0066] p'=average pressure on high parts (N / m 2 )

[0067] q = tangential pulling force on the wafer surface (N / m 2 )

[0068] r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com