Shaped metal article and method of producing shaped metal article having oxide coating

A technology for forming metal and covering layers, which is applied in the direction of metal layered products, chemical instruments and methods, metal material coating technology, etc., can solve the problems that the appearance and color of the covering layer cannot be freely controlled, and the conductivity cannot be fully controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

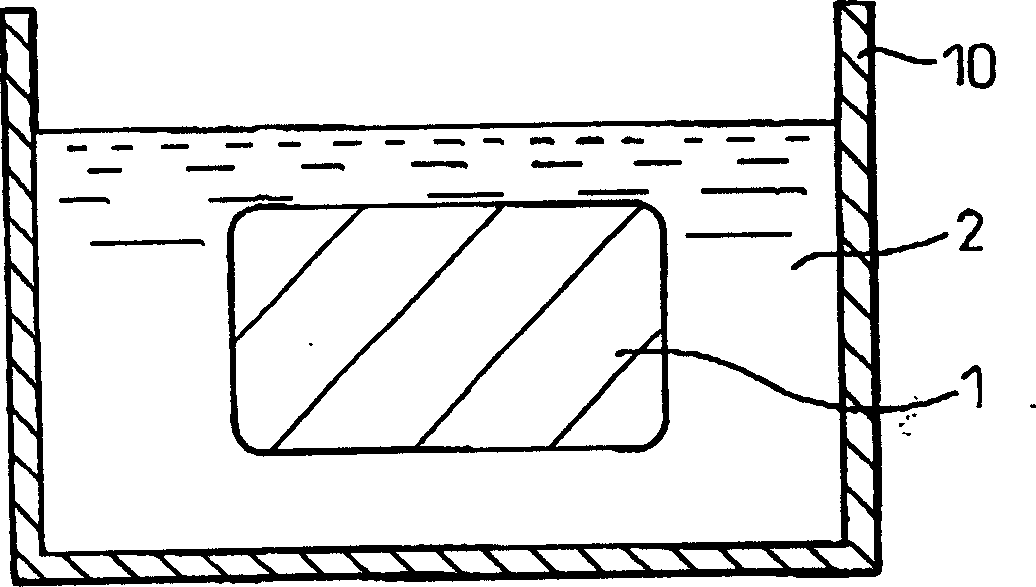

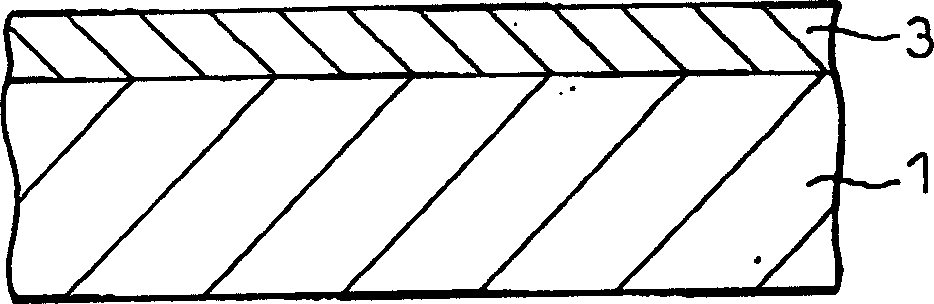

[0095] The purpose of this example is to refer to Figures 4 to 6 , describing the surface treatment of the shaped metal product according to a preferred embodiment of the present invention, wherein Figure 4 Shown is a flow chart of the method of making the shaped metal article, Figure 5 Shown is a schematic cross-sectional view of a conversion treatment tank used in the surface treatment of shaped metal articles, Figure 6 Shown is a schematic cross-sectional view of a shaped metal article produced after surface treatment with an oxide coating attached.

[0096] First, a magnesium alloy prepared by adding Al and Cu to Mg is formed by die casting to obtain a Mg alloy shaped product 11 having a predetermined shell structure (see Figure 5 ).

[0097] Next, pretreatment B is carried out to the formed Mg alloy product 11 1 . In preprocessing B 1 In this process, the surface of the molded product 11 is roughened by sandblasting to obtain a surface roughness R of about 0.1-...

Embodiment 2

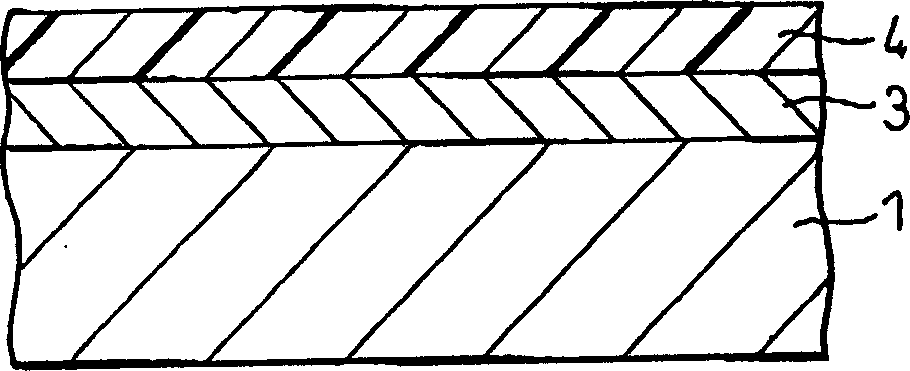

[0121] The purpose of this example is to refer to Figures 7 to 9 , illustrating the surface treatment of the shaped metal product according to another preferred embodiment of the present invention, wherein Figure 7 Shown is a flow chart of the method of making the shaped metal article, Figure 8 Shown is a schematic cross-sectional view of an anodizing tank for surface treatment of the shaped metal article, Figure 9 Shown is a schematic cross-sectional view of the resulting shaped metal article deposited with an oxide coating after anodizing.

[0122] The method described in Example 1 was repeated to produce a shaped Mg alloy article 11, which was then subjected to B 1 to B 6 preprocessing steps such as Figure 7 and Figure 8 shown. The surface of the shaped Mg alloy product 11 is thereby activated and cleaned.

[0123] Complete preprocessing step B 1 to B 6 Afterwards, non-chromium anodizing treatment C is carried out to the molded Mg alloy product 11 2 . For n...

Embodiment 3

[0142] The purpose of this example is to refer to Figures 10 to 11 , to describe the surface treatment of the shaped metal product according to another preferred embodiment of the present invention, wherein Figure 10 Shown is a flow diagram of a method of manufacturing a shaped metal article, Figure 11 Shown is a schematic cross-sectional view of a shaped metal article deposited with an oxide coating, the shaped metal article having a layer of epoxy resin coated thereon.

[0143] Repeating the method for manufacturing the shaped Mg alloy product 11 in Example 1 or Example 2, and then subjecting the shaped product 11 to a pretreatment step B, namely step B 1 to B 6 ,Such as Figure 10 shown. The surface of the shaped Mg alloy product 11 is thereby activated and cleaned.

[0144] Complete preprocessing step B 1 to B 6 Finally, carry out non-chromium (or claim chromium-free) surface treatment C to the molded Mg alloy product 11, namely conversion treatment C as describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com