Anodic carbon block vibrating and shaping method for aluminium

An anode carbon block and vibration forming technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of different heights of carbon blocks, easy cracking of carbon blocks, unfavorable for vacuuming, etc., so as to improve exhaust efficiency and eliminate carbon Block cracks, the effect of shortening the exhaust time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

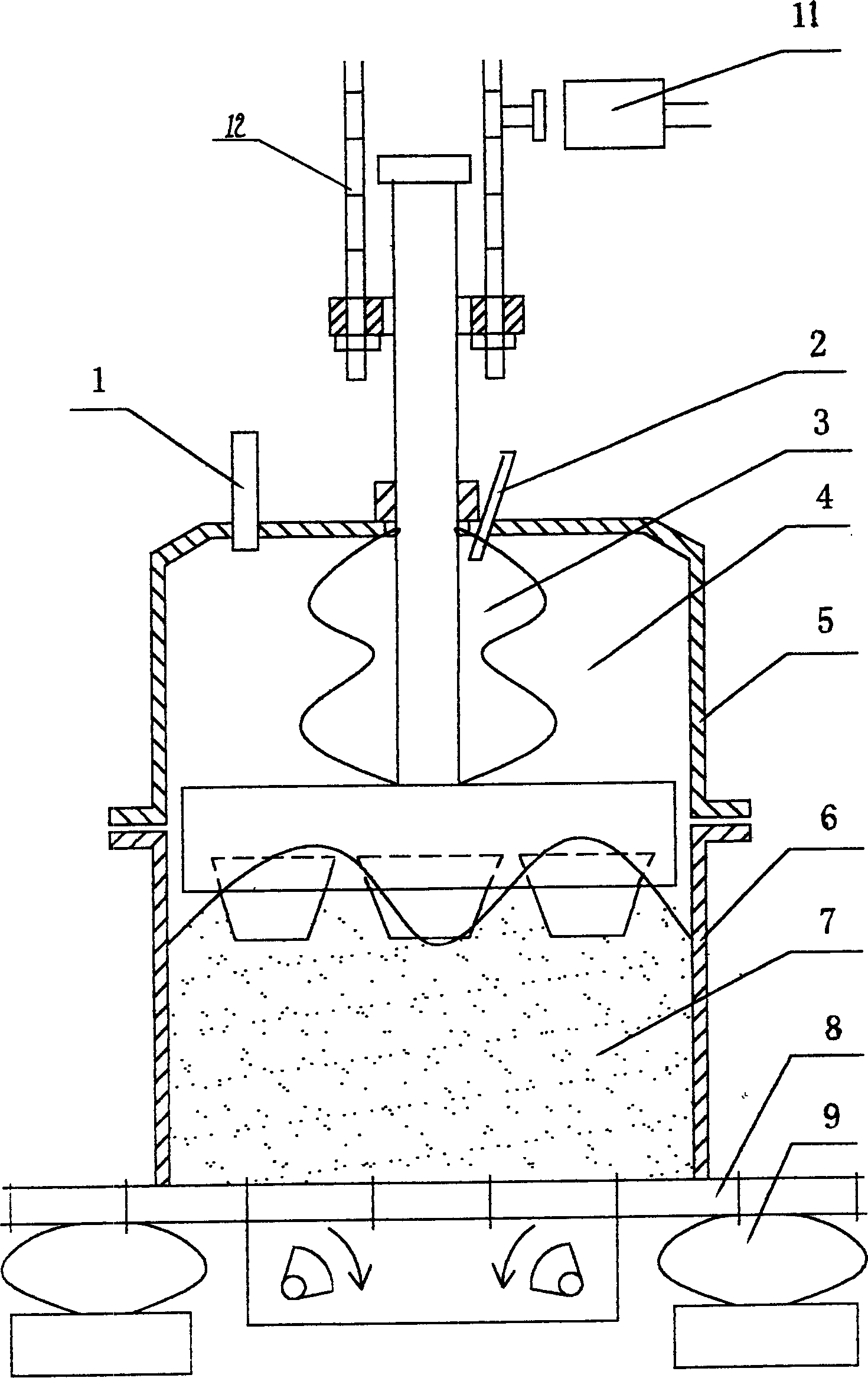

[0009] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

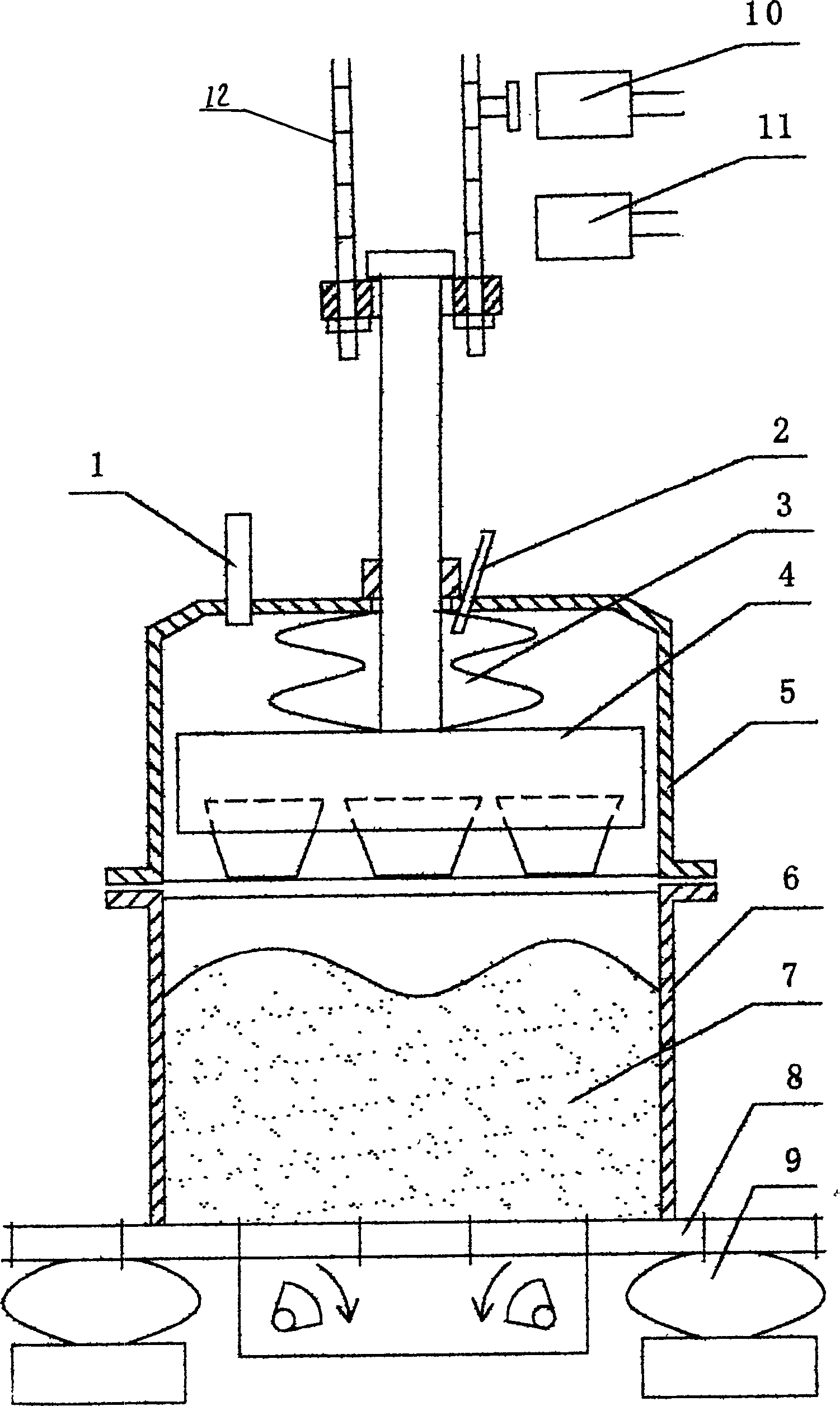

[0010] like figure 2 As shown, taking a fully automatic vacuum forming machine as an example, a proximity switch 10 is set during the descent of the weight 4 and the weight cover 5, that is, a proximity switch is set on the upper part of the pressing material proximity switch 11, so that the weight is in the process of falling. Stop in the middle.

[0011] The method of the present invention is as follows: first, the lifting chain 12 lifts the weight 4 and the weight cover 5, puts the paste 7 into the mold 6, lifts the airbag 9 to lift the biaxial vibrating table 8, and locks the mold 6. Then the weight 4 and the weight cover 5 are lowered, so that the weight cover 5 and the mold 6 are mutually locked, and now the proximity switch 10 is in place. The signal is sent into the program so that the heavy hammer 4 stops falling when it is close to the paste and does not pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com