Prepn process of metal oxide and sulfide nanometer linear array

A technology of nanowire arrays and oxides, applied in chemical instruments and methods, single crystal growth, polycrystalline material growth, etc., can solve problems such as difficult to obtain metal oxides with high specific surface area, achieve high crystallinity, high The effect of specific surface area and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

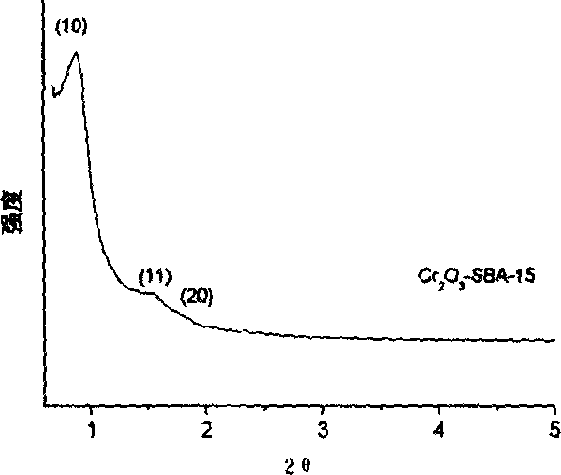

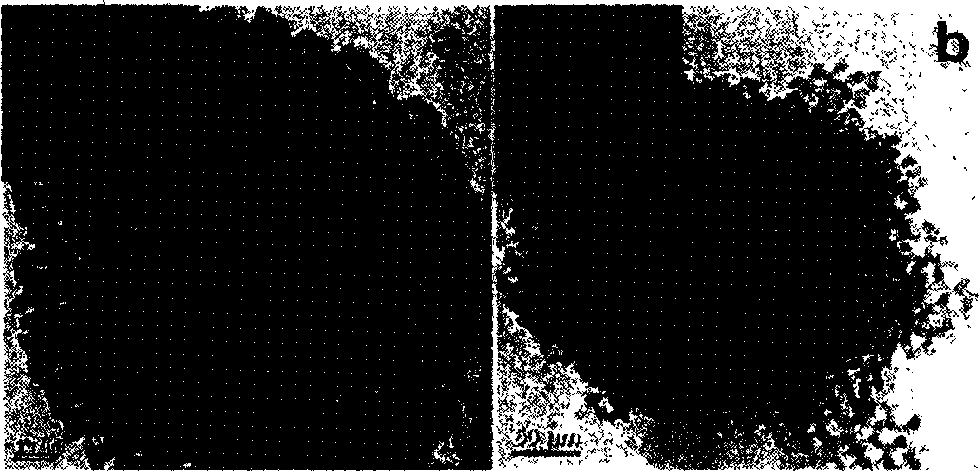

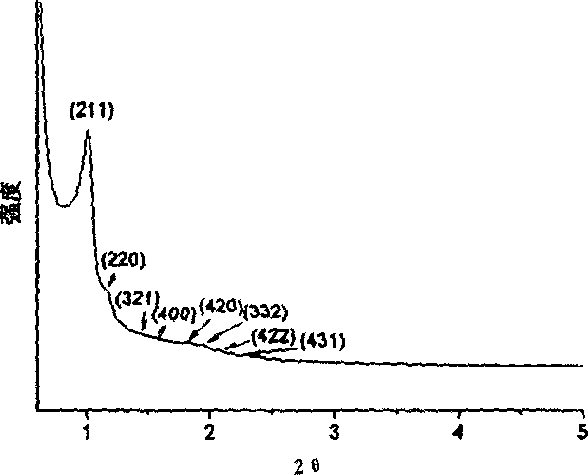

[0041] Example 1, the synthesis of chromium oxide nanowire arrays by in-situ thermal decomposition method: 0.20 g of mesoporous silica materials (SBA-15, FDU-5 and KIT-6) that have been roasted or microwave digested were dispersed in 6.0- In 10.0g ethanol, add 0.4-0.5g nitrate precursor (Cr(NO 3 ) 3 9H 2 O). Stir at room temperature for 2 hours, then evaporate ethanol to dryness at 40°C. The composite material is placed in a muffle furnace and fired at 350° C. for 2-4 hours to decompose nitrates to produce corresponding oxides. SiO after the above-mentioned roasting 2 / Cr 2 o 3 The composite material was dispersed again in 6.0-10.0 g of ethanol, and 0.2-0.3 g of nitrate was added. After stirring at room temperature for 2 hours, ethanol was evaporated to dryness at 40°C. The obtained material is calcined at 500° C. for 4-6 hours to decompose the newly added nitrate and complete the sintering and crystallization process of the material. Finally, the above materials were...

Embodiment 2

[0042] Example 2, the synthesis of tungsten oxide nanowire arrays by in-situ thermal decomposition method: 0.20g of mesoporous silicon oxide materials (SBA-15, FDU-5 and KIT-6) that had been roasted or microwave digested were dispersed in 6.0- In 10.0g ethanol, add 0.4-0.5g phosphotungstic acid (H 3 PW 12 o 40 ·nH 2 O). Stir at room temperature for 2 hours, then evaporate ethanol to dryness at 40°C. The composite material is placed in a muffle furnace and calcined at 350° C. for 2-4 hours to decompose the polyacid precursor to generate the corresponding oxide. SiO after the above-mentioned roasting 2 / WO 3 The composite material is dispersed again in 6.0-10.0 g of ethanol, and then 0.2-0.3 g of phosphotungstic acid is added. After stirring at room temperature for 2 hours, ethanol was evaporated to dryness at 40°C. The obtained material is calcined at 500° C. for 4-6 hours to decompose the newly added polyacid precursor, and to complete the sintering and crystallization...

Embodiment 3

[0043] Example 3, Synthesis of in-situ thermal decomposition of indium oxide nanowire arrays: 0.15 g of mesoporous silicon oxide materials (SBA-15, SBA-16, FDU-1, FDU-5, KIT-6) was dispersed in 5.0-8.0g ethanol, and 0.40-0.45g nitrate precursor (In(NO 3 ) 3 4.5H 2 O). After stirring at room temperature for two hours, the ethanol was evaporated to dryness at 40°C. The composite material is placed in a muffle furnace and fired at 250° C. for 2-4 hours to decompose the nitrate precursor. SiO after the above-mentioned roasting 2 / In 2 o 3 The composite material was dispersed again in 5.0-8.0 g of ethanol, and 0.25-0.35 g of nitrate was added. After stirring at room temperature for two hours, ethanol was evaporated to dryness at 40°C. The obtained material was calcined at 550° C. for 4-6 hours to decompose the newly added nitrate precursor and complete the final sintering and crystallization process of the material. The above materials were added to 20 mL of 2M sodium hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com