Multifunctional vision sensor with binocular spatial structure

A binocular stereo vision and vision sensor technology, applied in instruments, photogrammetry/video metrology, measuring devices, etc., can solve the problems of high cost, poor adaptability, long cycle, etc., and achieve the effect of low cost and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

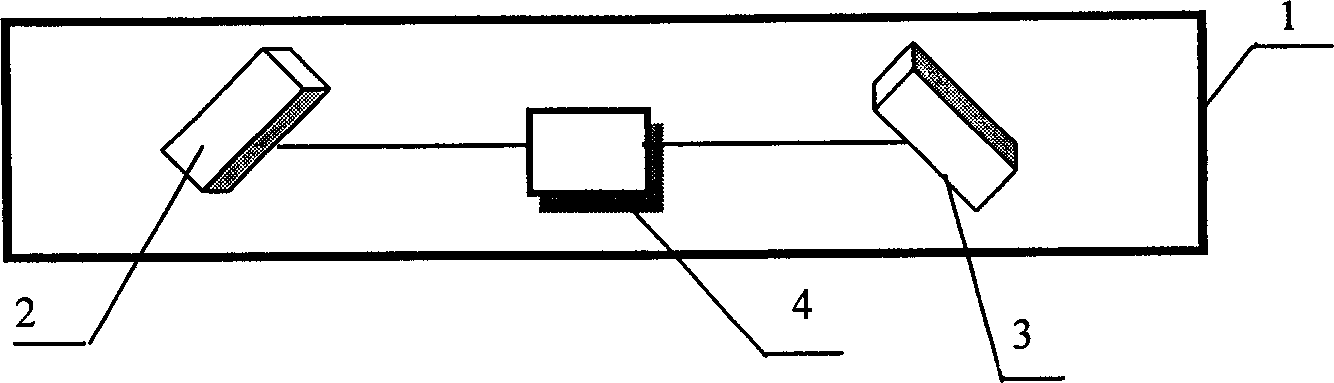

[0014] Embodiment one is a binocular three-dimensional structure multifunctional vision sensor applied in truck body vision detection, such as figure 1 shown in . The invention adopts two cameras, combines variable projectors, and builds a novel multi-functional visual sensor based on specific mold molding profiles. The binocular stereo structure multifunctional vision sensor includes a main body shell 1 . A first camera 2 , a variable projector 4 and a second camera 3 are arranged in sequence in the main body casing 1 . The two cameras 2 and 3 form a binocular stereoscopic vision measurement structure, and form a triangular relationship in space, meeting the requirements of the triangulation measurement principle. The variable projector can change different projection methods according to different measurement objects, and the installation mechanism is interchangeable. In this embodiment, the projection light source of the variable projector 4 is a lighting projection ligh...

Embodiment 2

[0017] The only difference from Embodiment 1 is that the projection light source of the variable projector 4 is a single light bar projection light source.

Embodiment 3

[0019] The only difference from Embodiment 1 is that the projection light source of the variable projector 4 is a multi-strip projection light source.

[0020] The projection light sources of the variable projector 4 of the present invention are not limited to the above three forms, and may also be other types of characteristic light sources.

[0021] Compared with the existing sensor realization technology, the remarkable feature of the present invention is that it uses a binocular three-dimensional structure, a unified calibration method, combined with a variable projector, and adopts a specific mold sensor shell main body molding technology, which can realize multi-functional measurement and simultaneous processing Simple and low cost, it can be used in high-volume, high-precision field measurement applications. The present invention applies the binocular three-dimensional structure multifunctional design technology to the design of the visual sensor for the first time, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com