Image-forming composition for heat-sensitive CTP image base, acid generating source for the composition and preparation thereof

An imaging composition and heat-sensitive technology, which can be used in printing plate preparation, optomechanical equipment, photosensitive material processing, etc., and can solve the problems of low printing durability, poor industrialization and commercialization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] The present invention will be described in detail below with reference to Examples.

preparation Embodiment 1

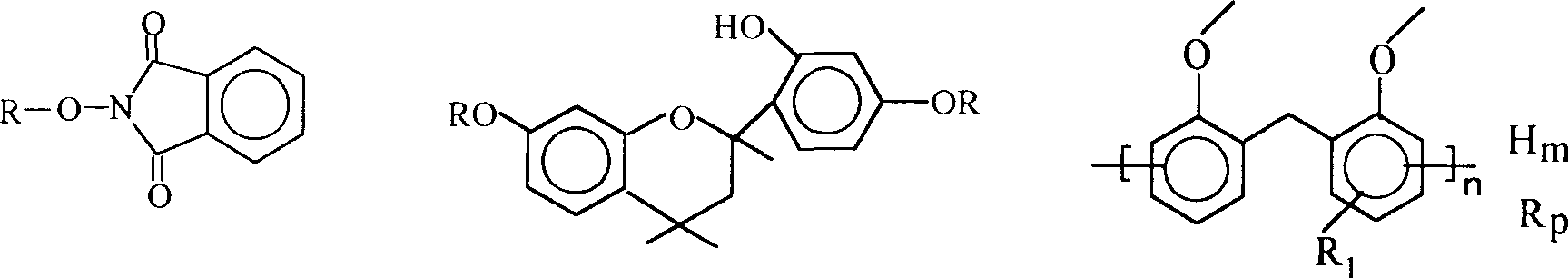

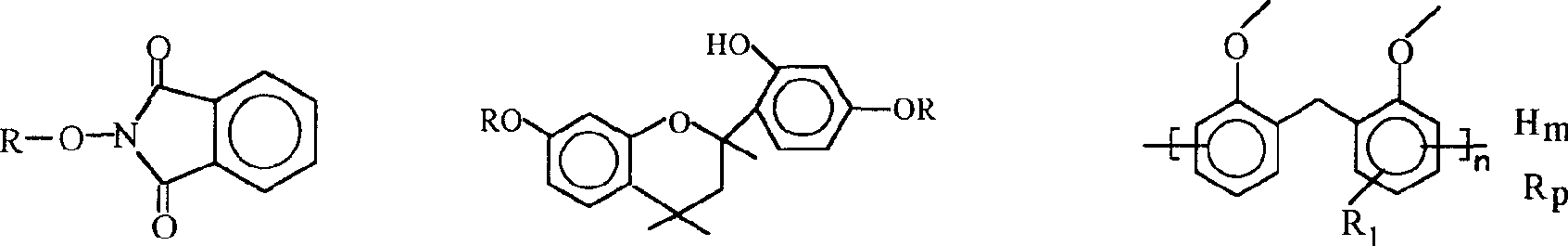

[0057] The method for synthesizing 2,1,4-diazonaphthoquinone sulfonyloxyphthalimide ester with N-hydroxyphthalimide and 2,1,4-diazonaphthoquinone sulfonyl chloride

[0058] Get 8.15g (0.05mol) of N-hydroxyphthalimide, 13.4g (0.05mol) of 2,1,4-diazonaphthoquinonesulfonyl chloride, add 50ml N,N-dimethylformamide and 60ml Acetone, stirred to dissolve. Raise the temperature of the system to 30°C, drop a drop of 5% dilute sulfuric acid into the system, and then slowly add 5% tris Ethylamine, when the pH value of the system is about 7, pour the reaction solution into distilled water 10 times its volume, and precipitate the product. After soaking for several hours, filter it with suction, and then dry it at about 40°C to obtain a yellow powder solid , and the yield was 84%.

preparation Embodiment 2

[0060] Method for synthesizing 2,1,4-diazonaphthoquinone sulfonate by condensate of resorcinol and acetone and 2,1,4-diazonaphthoquinone sulfonyl chloride

[0061] Get 15g resorcinol acetone (0.05mol) produced by Tiancheng Chemical Company, Weihai Economic and Technological Development Zone, Shandong, 26.8g (0.1mol) 2,1,4-diazonaphthoquinone sulfonyl chloride, be dissolved in 300ml acetone, stir dissolve. Raise the temperature of the system to 35°C, drop 10% Na within 1 hour through the dropping funnel 2 CO 3 Aqueous solution 58.3g (equivalently containing 0.055mol). After the dropwise addition, keep the reaction at 35-40°C for 1 hour, then pour the reaction liquid into 10 times the amount of distilled water, adjust the pH value to 6.5 with dilute HCl, precipitate the product, filter, and rinse with distilled water for 3 times , and dried at 40-50°C to obtain a yellow powder solid product with a yield of 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com