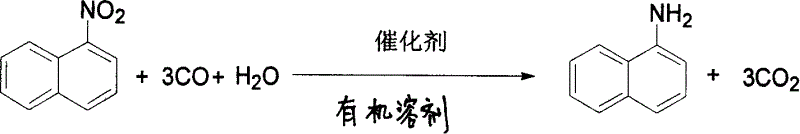

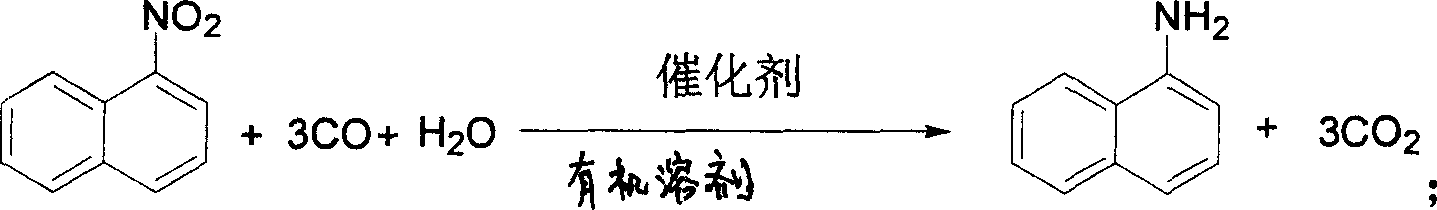

Method for synthesizing 1-amino naphthalenes

A technology of aminonaphthalene and nitronaphthalene, applied in the field of synthesis of 1-aminonaphthalene, can solve the problems of non-universality, serious environmental pollution, complicated operation, etc., and achieve low reaction process difficulty, high reaction selectivity, and simple raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 1-nitronaphthalene (10mmol), Se (0.4mmol), H 2 O (0.1mol), triethylamine (5mmol) and solvent DMF (40ml), continue to pass carbon monoxide, then heat to 88 ° C and stir for 4 hours, cool to room temperature, switch carbon monoxide to oxygen or air and stir for 0.5-1 hour Finally, the selenium powder is filtered out, and after the filtrate obtained by filtering is concentrated, the content is determined by gas chromatography, and the chromatographic yield of 1-aminonaphthalene is 100% (in terms of 1-nitronaphthalene). The content determination adopts HP-4890D gas chromatography system, including FID detector, SE-54 capillary column (30m×0.32mm×1.5μm), vaporization chamber temperature: 280°C, column temperature: 250°C, external standard method for quantification.

Embodiment 2

[0019] The solvent is formylpiperidine, and the reaction time is 10 hours. Other experimental methods and conditions are the same as in Example 1. The yield of 1-aminonaphthalene measured by gas chromatography is 50% (calculated as 1-nitronaphthalene).

Embodiment 3

[0020] Embodiment 3: solvent is DMSO, and the reaction time is 3 hours, and other experimental methods and conditions are the same as embodiment 1, and the yield of 1-aminonaphthalene measured by gas chromatography is 100% (calculated as 1-nitronaphthalene).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com