Process for vacuum linear source evaporation coating film and its apparatus

An evaporation coating and line source technology, applied in the field of evaporation coating, can solve the problems of low utilization rate of evaporation materials, difficult control, fast evaporation speed, etc., and achieve the effect of increasing effective utilization rate, convenient adjustment and control, and less film defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

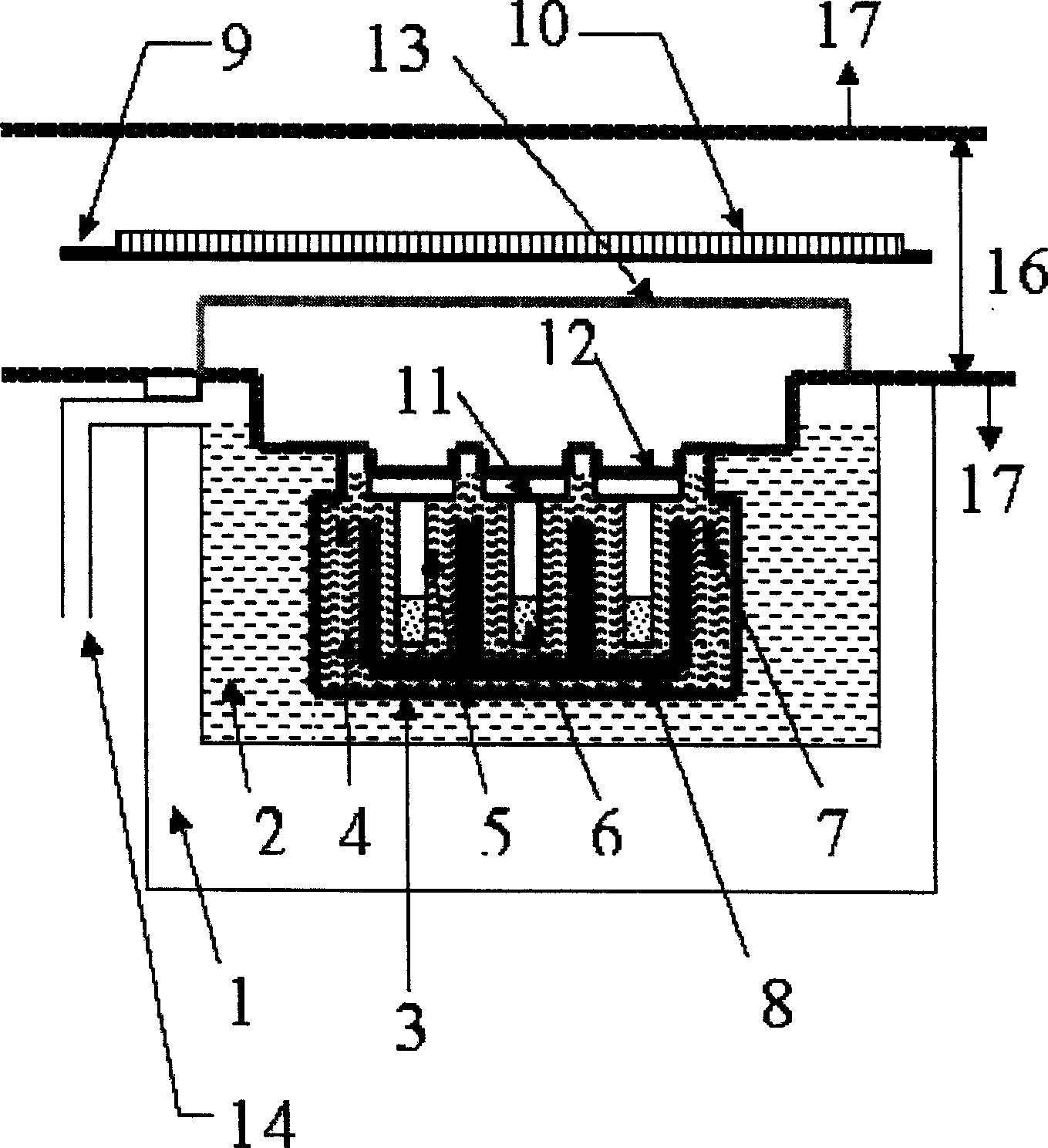

[0023] The present invention is further illustrated by embodiments in conjunction with the accompanying drawings.

[0024] In the vacuum line source evaporation device of the present invention, the external dimensions of the device are determined according to the size of the coating substrate. The heating source 1 is a precision heater, which is composed of a heater and an oil agitator. The temperature range is 50°C to 350°C, and it contains the first heat-conducting substance 2. There is an air duct 14 to remove the oily fume generated by the first heat-conducting substance. Here, the first heat-conducting substance adopts high-temperature heat-conducting oil, and the temperature non-uniformity of the oil is less than or equal to ±1°C when the temperature of the heater is constant, and the temperature fluctuation of a single point is less than or equal to ±1°C. Both the precision heater 1 and the first heat-conducting substance 2 are placed outside the vacuum system.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com