Silicon tetrachloride energy-saving vaporizer

A technology of silicon tetrachloride and vaporizer, which is applied in the direction of silicon halide compounds, chemical instruments and methods, inorganic chemistry, etc., and can solve the problems of turbulent flow of silicon tetrachloride, small contact area of electric heating rod, large heating capacity of heat transfer oil, etc. problem, to achieve the effect of simple structure, large heating contact area and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

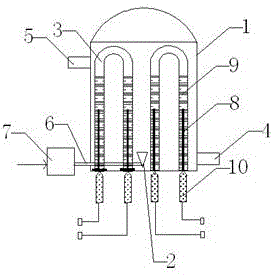

[0018] A silicon tetrachloride energy-saving vaporizer, comprising: a vaporizer shell 1, a hydrogen distributor 2 and a closed heating tube 3.

[0019] Wherein, a silicon tetrachloride inlet 4 and a silicon tetrachloride steam outlet 5 are opened at the bottom and top of the two opposite walls of the vaporizer housing 1 respectively.

[0020] The hydrogen gas distributor 2 is an inverted conical structure, and air holes are evenly distributed on its conical surface, which is used to spray hydrogen downward to mix with silicon tetrachloride gas components. The number of the hydrogen gas distributor 2 is 1 to 3 pieces, evenly placed on the bottom of the carburetor shell 1, the bottom end of which communicates with an insertion tube 6 for supplying hydrogen flow, the other end of the insertion tube 6 protrudes from the outside of the carburetor shell 1, and is connected to There is a hydrogen buffer tank 7, so that hydrogen flows into the hydrogen distributor 2 at a uniform and g...

Embodiment 2

[0024] The difference from Embodiment 1 is that the two tube arms of the closed heating tube 3 are equipped with electric heating rods 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com