Method of preparing nanometer magnesium oxide using uniform precipitation-supercritical carbon dioxide drying method

A nano-magnesium oxide, uniform precipitation technology, applied in the direction of magnesium oxide, can solve the problem of serious agglomeration, achieve good adsorption performance, lower operating temperature and pressure, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

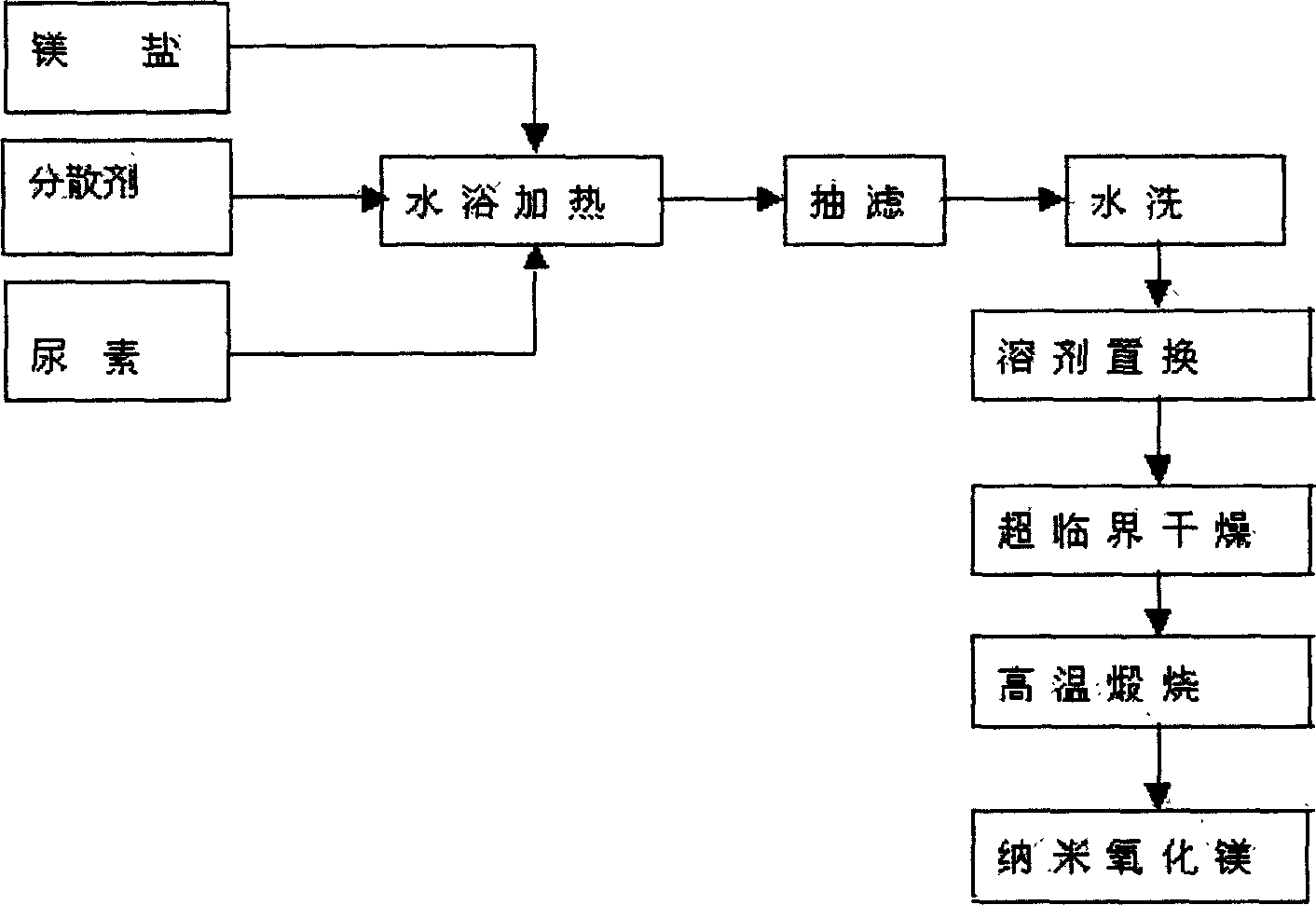

Method used

Image

Examples

Embodiment Construction

[0027] (1) 101.5 grams of magnesium chloride hexahydrate, 120.0 grams of urea and 250 grams of water are put into a three-necked flask of 1000 milliliters, and 1.0 grams of polyethylene glycol-1000 and 0.8 grams of polyethylene glycol-400 are added simultaneously, and the water bath is heated to 363K, React for 4 hours, age for 5 hours, filter with suction, wash with deionized water until no chloride ion is detected by silver nitrate solution.

[0028] (2) The precipitate was washed 10 times with absolute ethanol, then soaked for 24 hours, filtered with suction, and washed 6 times to ensure that the water was completely replaced.

[0029] (3) The product obtained in (2) is put into a supercritical dryer, and the CO from the steel cylinder 2 After the gas is liquefied by the condenser, pressurized by the high-pressure pump and heated by the heater, the gas reaches a supercritical state, and maintains a constant temperature and pressure at 16MPa and 333K for 3 hours. When the et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com