Method for making nano-scale metal powder and method for making high-frequency soft magnetic core using same

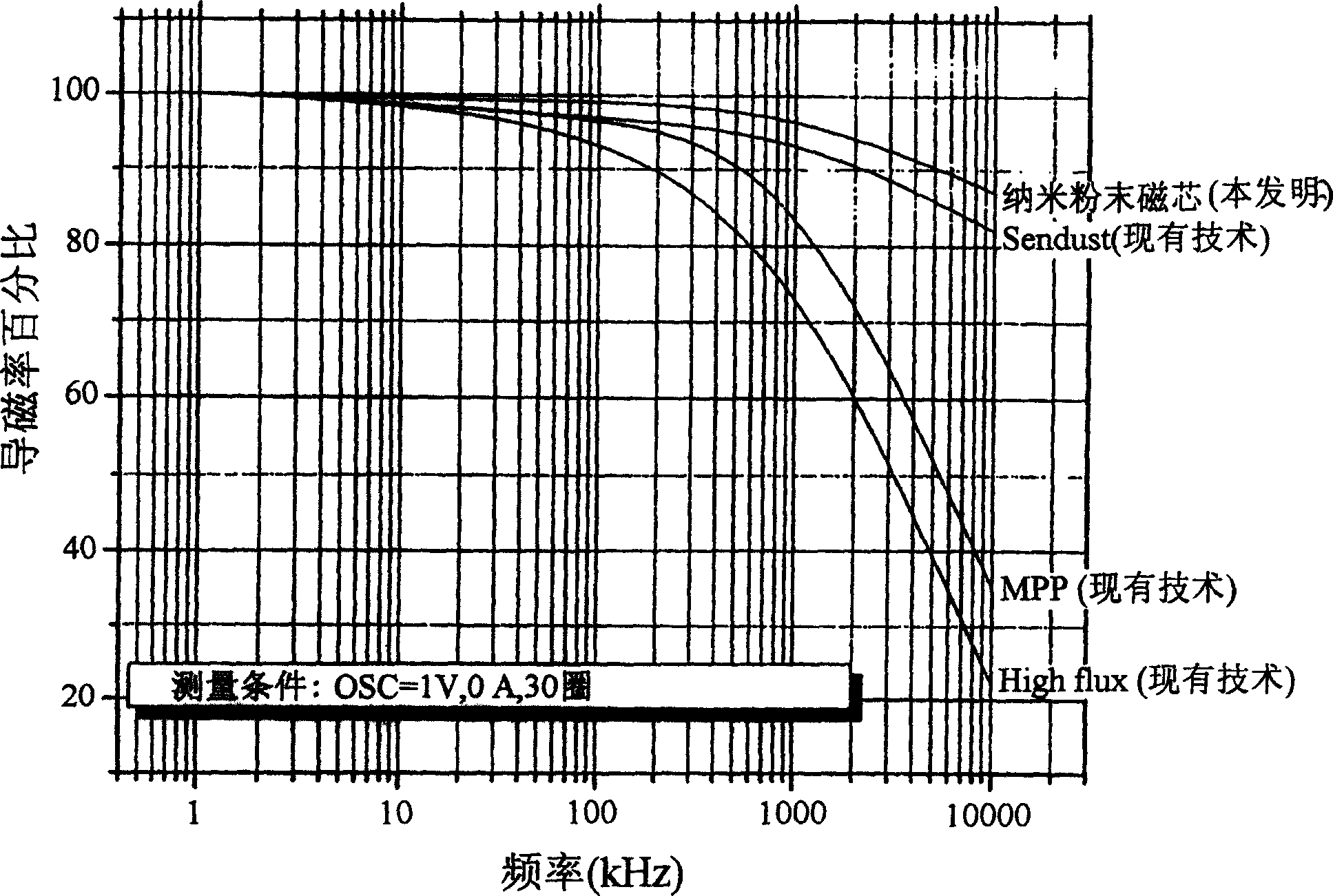

一种金属粉末、软磁芯的技术,应用在金属加工设备、纳米结构制造、纳米技术等方向,能够解决导磁率降低等问题,达到涡电流损耗小、降低处理成本、佳热稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

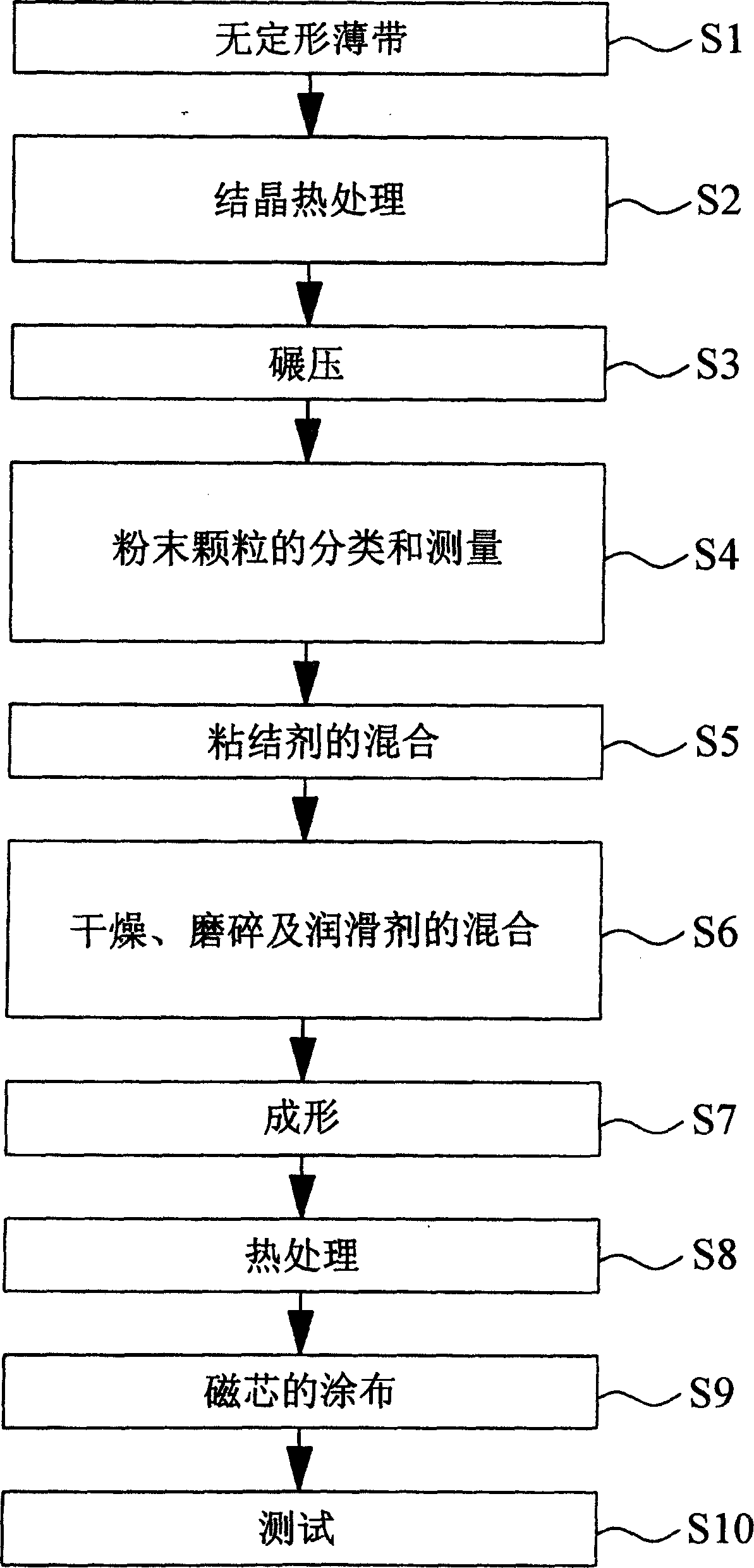

Method used

Image

Examples

Embodiment 1

[0046] The Fe-containing 73.5 Cu 1 Nb 3 Si 13.5 B 9 The amorphous ribbons of the components were heat-treated in nitrogen at 540° C. for 40 minutes to obtain nanoscale grain ribbons. Such as figure 2 As shown, the size of the crystalline grains is 10 to 15 nm. After crushing the thin ribbon of nano-sized grains by using a crusher, the powder particles are classified and measured to obtain 50% powder passing through -100~+140 mesh and 50% passing through -140~+200 mesh purpose powder.

[0047] Then, the prepared nanoscale grain powder was mixed with 3 wt % of low-melting glass, and then dried. After drying, the bulk powder mixed with low-melting glass was re-rolled using a ball mill, and then 0.5 wt% of Zn-stearate was added to and mixed with the rolled powder. Thereafter, use a core forming die at 16 tons / cm 2 The powder mixed with Zn-stearate was molded under a molding pressure of 100 to obtain a ring magnetic core.

[0048] Thereafter, the magnetic core molded bod...

Embodiment 2

[0058] In Example 2, the magnetic permeability of the ribbon and the size of the crystalline grains were measured, wherein the grains were crystallized at the nanoscale and heat-treated the amorphous metal ribbon in nitrogen at a temperature of 380 to 620° C. 2 hours and got it. Figure 5 Showing the change in magnetic permeability with the change in heat treatment temperature, Table 2 shows the size of crystal grains according to heat treatment temperature and heat treatment time.

[0059] exist Figure 5 In , the magnetic permeability is compared according to the most suitable time, which is the magnetic permeability in the thin strip state. Only when the magnetic permeability in the ribbon state is 15000 or higher, a magnetic permeability of 125 or higher is exhibited at 100 kHz and 1 V after the core is formed.

[0060] From Figure 5 As can be seen in , a magnetic permeability of 15,000 or higher is exhibited in the range of 400 to 600°C, while no such magnetic permeab...

Embodiment 3

[0065] In the same manner as in Example 1, an amorphous thin tape was obtained. Among the powder particles of the nanoscale metal powder, 70% of the powder passes through the mesh of -100 to +140, and 30% of the powder passes through the mesh of -140 to +200. When the magnetic core is formed by an extrusion molding machine, cracks may appear on the surface of the magnetic core after the magnetic core is formed. Thus, after heat treatment, the magnetic core can crack.

[0066] If the powder passing -100 ~ +140 mesh is 65% or more, it can be seen from the experiment of changing the powder particle distribution of the metal powder that cracks will appear during the forming process and a magnetic core with the desired characteristics cannot be obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com