Thin film transistor and producing method thereof

A technology of thin film transistors and manufacturing methods, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of deterioration of working characteristics of thin-film transistors, and achieve the effect of excellent working characteristics and pollution suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

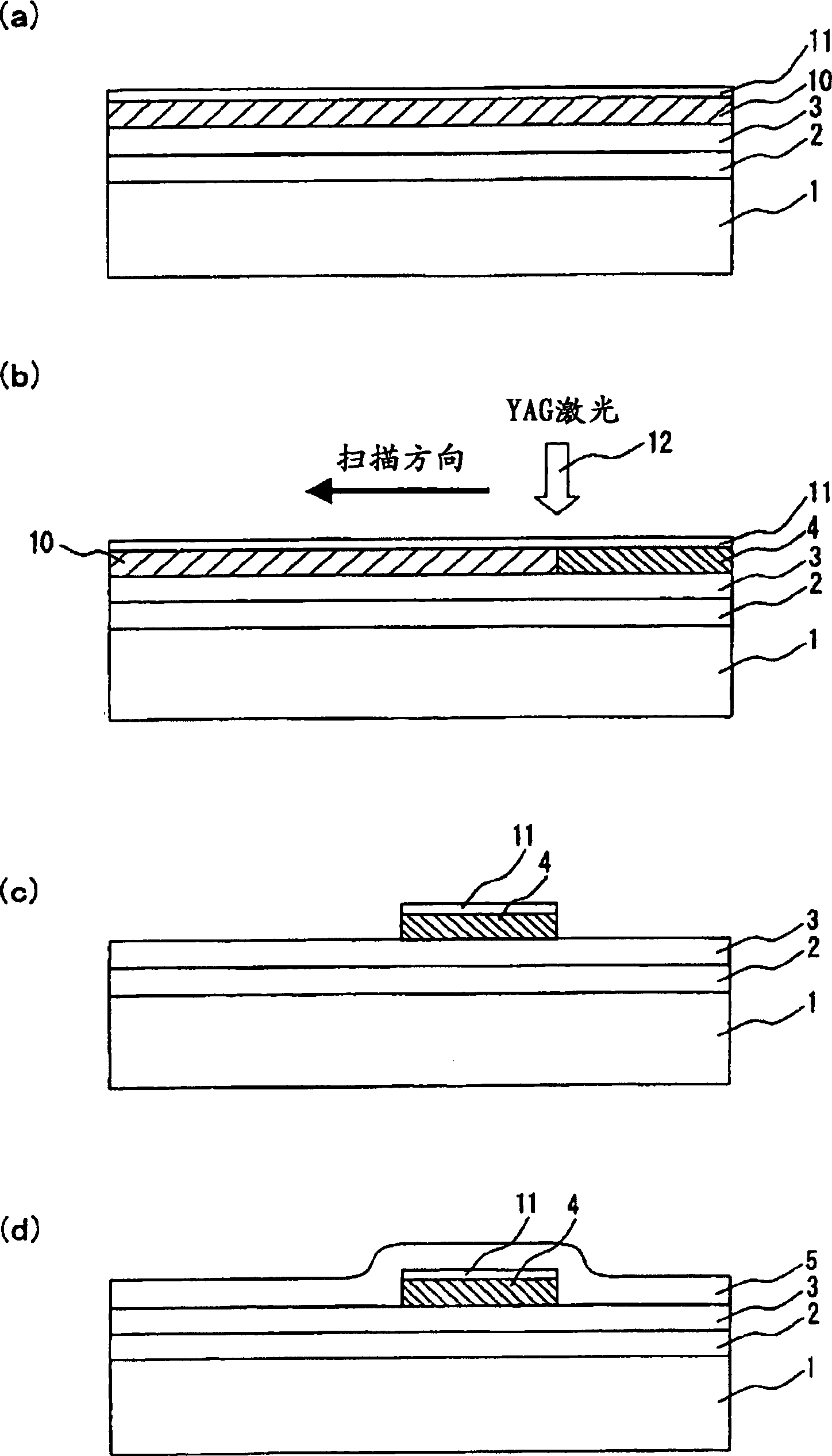

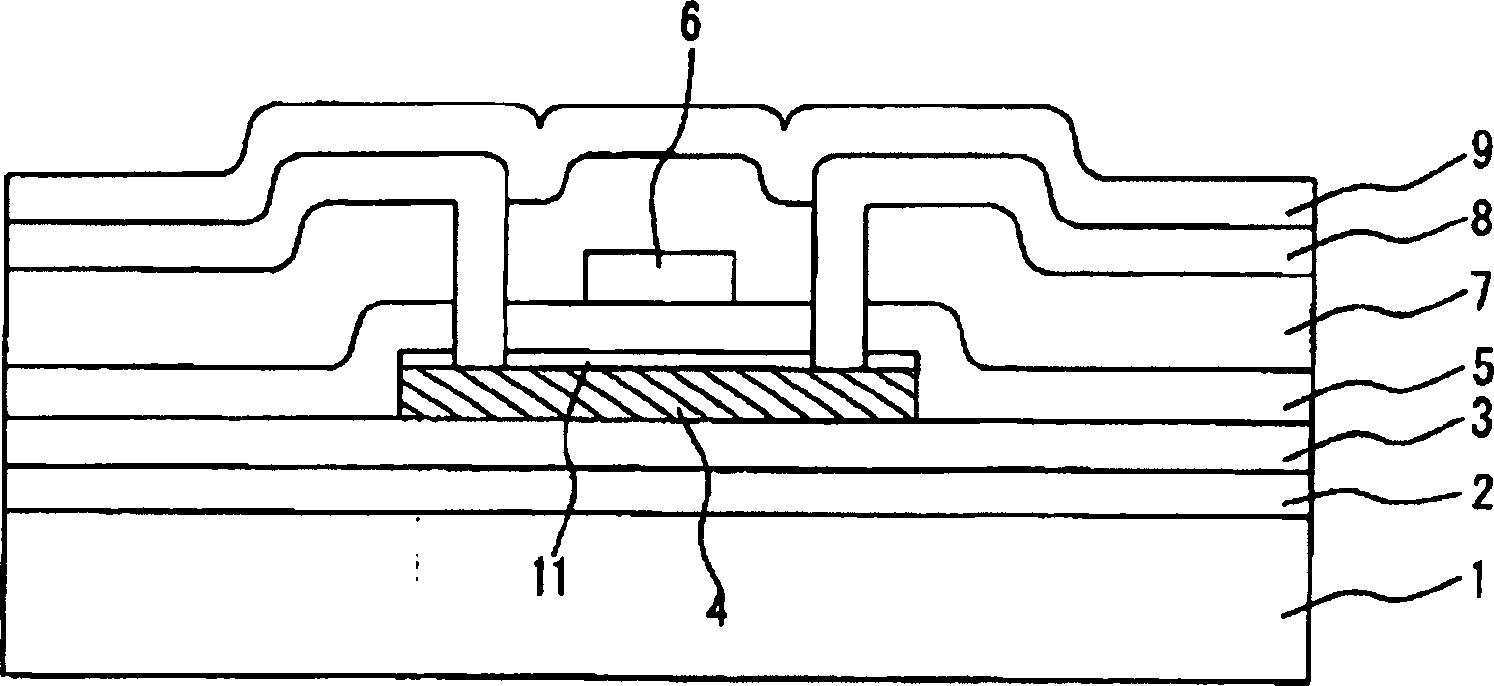

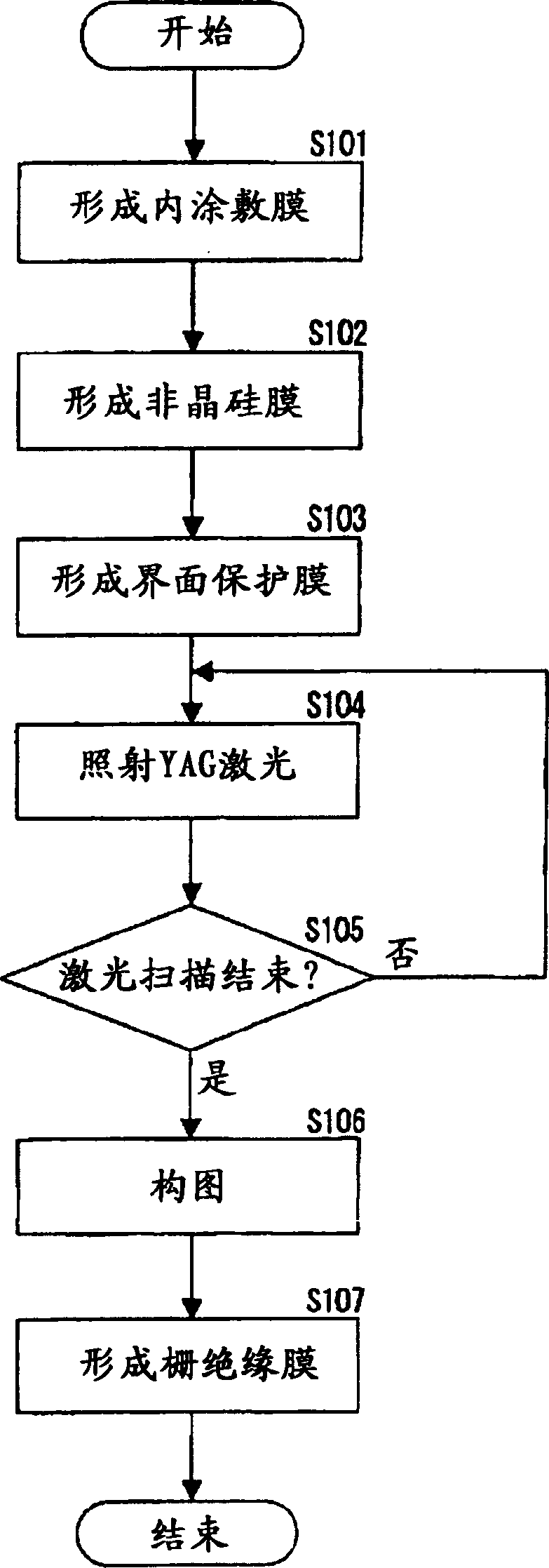

[0044] figure 1 (a)~ figure 1 (d) shows an example of the main part of the method for manufacturing a low-temperature polysilicon TFT according to Embodiment 1 of the present invention, and shows steps up to the formation of the gate insulating film 5 .

[0045] The insulating substrate 1 is an insulating transparent substrate such as a glass substrate, on which a silicon nitride film 2, a silicon oxide film 3, an amorphous silicon film 10, and a silicon oxide film 11 are sequentially formed. ( figure 1 (a) process). The amorphous silicon film 10 is an amorphous silicon film that is polycrystallized by laser irradiation described later and becomes an active semiconductor layer by ion doping. Both the silicon nitride film 2 and the silicon oxide film 3 are insulating undercoat films for stabilizing the characteristics of the semiconductor layer. The silicon oxide film 11 is an insulating interface protection film that prevents the amorphous silicon film 10 from being exp...

Embodiment approach 2

[0071] In Embodiment Mode 1, a method of manufacturing a thin film transistor in which the silicon oxide film 11 as an interface protective film is left is described. In this manufacturing method, until the silicon oxide film 5 serving as the gate insulating film is formed, it is considered that a native oxide film is formed on the surface of the silicon oxide film 11, and the defect level increases. Such a silicon oxide film 11 remains between the polysilicon film 4 and the gate electrode 6 of the thin film transistor. On the contrary, in this embodiment mode, by removing the silicon oxide film 11 after the photolithographic patterning, the operating characteristics as a thin film transistor are further improved.

[0072] Figure 4 Steps S201 to S208 are a flowchart showing an example of main parts in the method of manufacturing a low-temperature polysilicon TFT according to Embodiment 2 of the present invention. From step S201 to step S206, and from image 3 The processin...

Embodiment approach 3

[0075] Figure 7 is a diagram showing an example of the main part of the method for manufacturing a low-temperature polysilicon TFT according to Embodiment 3 of the present invention, and figure 1 In the same manner as Embodiment 1 shown, each step up to the formation of the gate insulating film 5 is shown.

[0076] The insulating substrate 1 is an insulating transparent substrate such as a glass substrate, on which a silicon nitride film 2, a silicon oxide film 3, an amorphous silicon film 10, and a silicon oxide film 11 are sequentially formed. ( Figure 7 (a) process). The amorphous silicon film 10 is an amorphous silicon film that is polycrystallized by laser irradiation and becomes an active semiconductor layer by ion doping. Both the silicon nitride film 2 and the silicon oxide film 3 are insulating undercoat films for stabilizing the characteristics of the semiconductor layer. The silicon oxide film 11 is an insulating interface protection film that prevents the am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com