Milling roller of flour mill, method for machining milling teeth on milling roller surface and use of milling roller

A processing method and milling machine technology, applied in the field of milling rollers, can solve the problems of low unit flow rate and powder extraction rate of smooth rolls, affecting output and grinding effect, and low powder extraction rate, so as to reduce production consumption and Equipment investment, improvement of crushing and grinding effects, improvement of hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

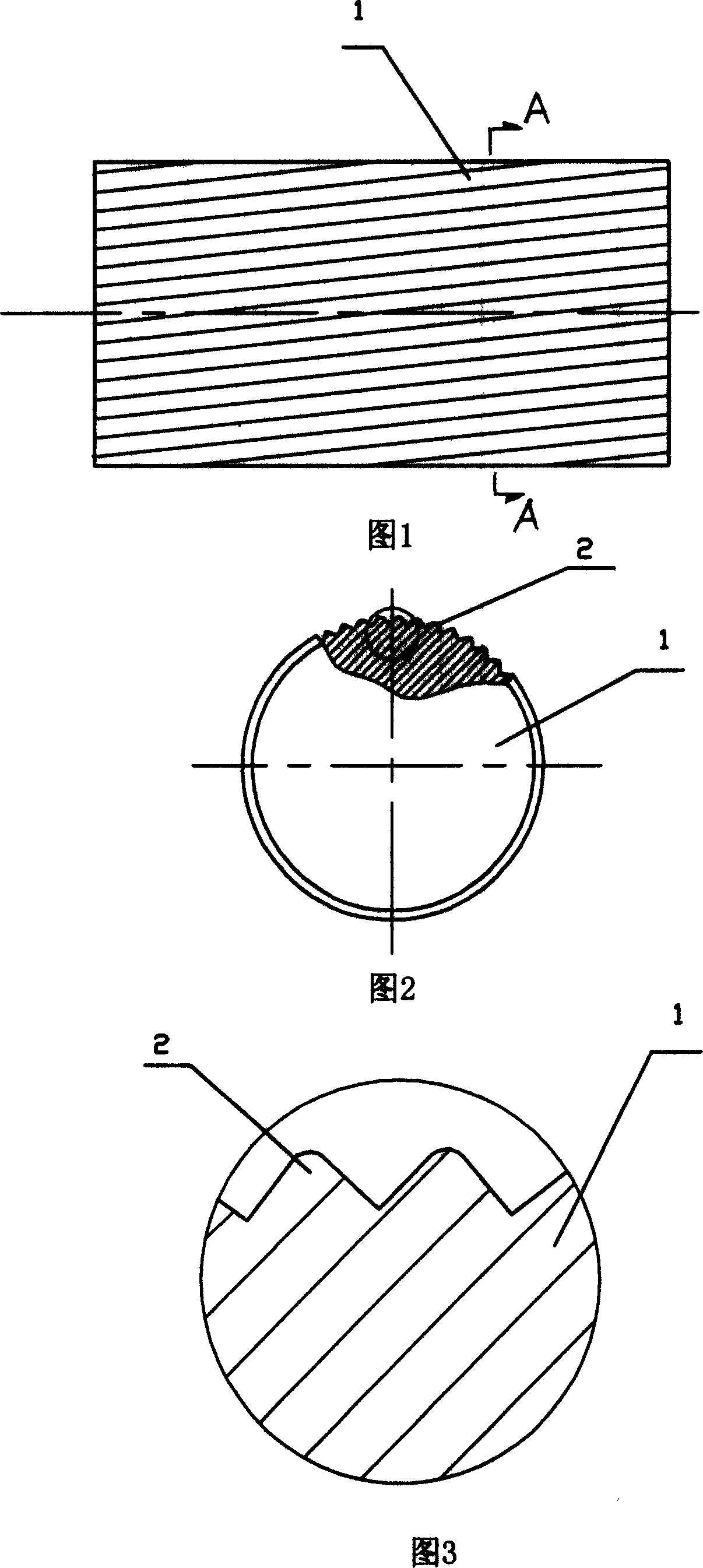

[0049] The diameter of the grinding roller 1 is 220 mm and the length is 500 mm. The number of teeth of the drawing grinding teeth 2 is 3.15 teeth / cm, the tooth height is 0.85 mm, the distance between the grinding teeth 2 is 3.17 mm, the sharp angle of the drawing grinding teeth 2 is 22°, and the obtuse angle is 68°, the inclination of grinding teeth 2 is 6%, the tooth top plane is 0.2mm, and the speed ratio of fast and slow rolls is 2.5:1.

[0050] The specific operating process parameters of plasma treatment on the surface of grinding roller 1 are: voltage 220V, current 92A, air pressure 0.95MPa, temperature 7600°C, grinding roller speed 32r / min, gun head running speed 0.2m / min, treatment cycle 4, treatment time It is 16min. The average radius of the tooth top after treatment is 0.4mm.

[0051] flow

Embodiment 2

[0053] The diameter of the grinding roller 1 is 250 mm, the length is 1000 mm, the number of teeth of the drawing grinding teeth 2 is 8.7 teeth / cm, the tooth height is 0.061 mm, the distance between the grinding teeth 2 is 1.155 mm, the sharp angle of the drawing grinding teeth is 30°, and the obtuse angle is 80° °, the inclination of the grinding tooth 2 is 6%, the tooth top plane is 0.1 mm, and the speed ratio of the fast and slow rolls is the conventional drawing grinding roll of 2.0:1.

[0054] The specific operating process parameters of plasma treatment on the surface of grinding roller 1 are: voltage 220V, current 92A, air pressure 0.9MPa, temperature 7200°C, grinding roller speed 32r / min, gun head running speed 0.2m / min, treatment cycle 3, treatment time It is 22min. The average radius of the tooth top after treatment is 0.22mm.

[0055] flow

Embodiment 3

[0057] The diameter of the grinding roller 1 is 215mm, the length is 350mm, the number of teeth of the drawing grinding teeth 2 is 5.5 teeth / cm, the tooth height is 0.5mm, the distance between the grinding teeth 2 is 1.82mm, the sharp angle of the drawing grinding teeth is 28°, and the obtuse angle 62°, the inclination of grinding teeth 2 is 15%, the tooth top plane is 0.15mm, and the speed ratio of fast and slow rolls is 2.5:1.

[0058] The specific operating process parameters of plasma treatment on the surface of grinding roller 1 are: voltage 220V, current 100A, air pressure 0.96MPa, temperature 7600°C, grinding roller speed 32r / min, gun head running speed 0.18m / min, treatment cycle 4, treatment time 12min. The average radius of the tooth top after treatment is 0.35mm.

[0059] flow

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com