Carbon source denitrogenation inside cells for sewage

A carbon source nitrogen method and denitrification technology, applied in the field of environmental protection, can solve the problems of low denitrification efficiency, high infrastructure costs, and difficulty in controlling the dosage, so as to improve the denitrification efficiency, reduce the amount of excess sludge, and save all resources. The effect of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

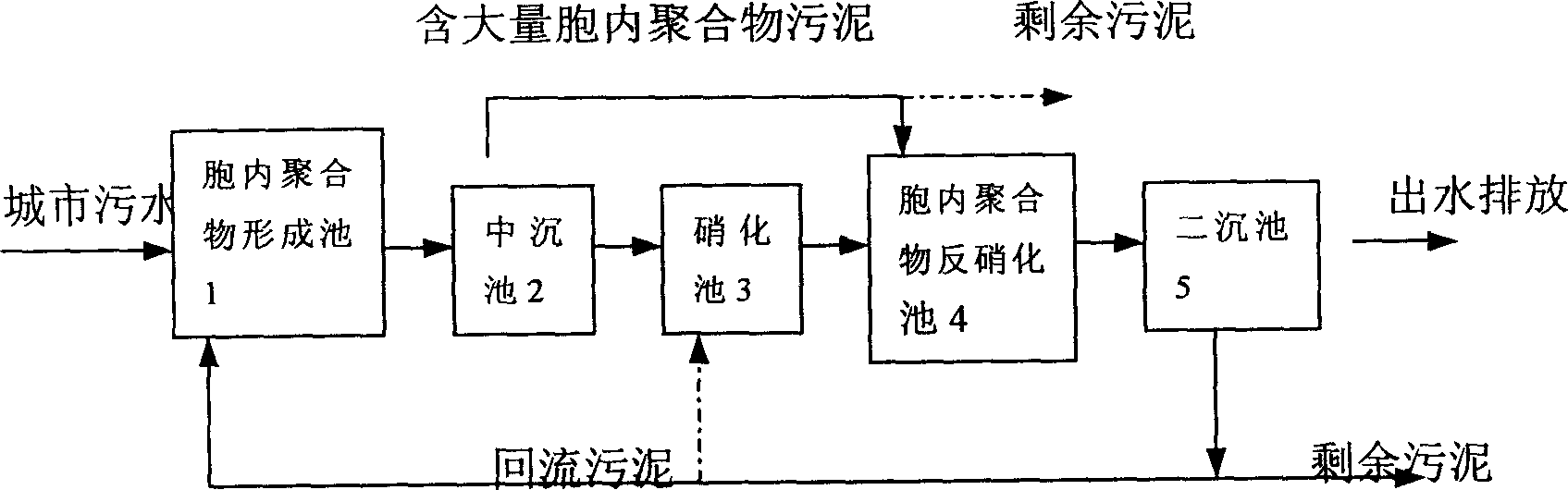

[0037] The urban sewage from a certain place is pretreated by grille, grit and primary sedimentation, and then mixed with the return sludge from the secondary sedimentation tank in the intracellular polymer formation tank. The hydraulic retention time is 40 minutes, and the dissolved oxygen is controlled. At about 2mg / l, the mixed solution from the intracellular polymer formation tank enters the intermediate sedimentation tank, and the sedimentation time is 1.5 hours. The sedimentation sludge flows into the intracellular polymer denitrification tank, and the supernatant enters the nitrification tank (using Soft fiber packed bed reactor), the hydraulic retention time is 6 hours, and the dissolved oxygen is controlled at about 3.5mg / l. The sludge phase of the inner polymer is mixed, and the hydraulic retention time is 1.0 hour, and the underwater low-speed submersible mixer is used for mixing. The mixed liquid flowing out from the intracellular polymer denitrification tank enter...

Embodiment 2

[0040] The urban sewage from a certain place is pretreated by grille, grit and primary sedimentation, and then mixed with the return sludge from the secondary sedimentation tank in the intracellular polymer formation tank. The hydraulic retention time is 30 minutes, and the dissolved oxygen is controlled. Around 2mg / l. The mixed solution from the intracellular polymer formation tank enters the intermediate sedimentation tank, and the sedimentation time is 1.5 hours. The sedimentation sludge flows into the intracellular polymer denitrification tank, and the supernatant enters the nitrification tank (soft fiber packed bed reactor) ), the effective residence time is 4.5 hours, and the dissolved oxygen is controlled at about 3mg / l. The liquid flowing out from the nitrification tank enters the intracellular polymer and the nitrification tank, and is mixed with the sludge containing a large amount of intracellular polymer from the intermediate sedimentation tank. The hydraulic reten...

Embodiment 3

[0043] The urban sewage from a certain place is pretreated by grille, grit and primary sedimentation, and mixed with the return sludge from the secondary sedimentation tank in the intracellular polymer formation tank. The hydraulic retention time is 20 minutes, and the dissolved oxygen is controlled. At about 2 mg / l, the mixed solution from the intracellular polymer formation tank enters the intermediate sedimentation tank, and the sedimentation time is 1.5 hours. The sedimentation sludge flows into the intracellular polymer denitrification tank, and the supernatant enters the nitrification tank (soft fiber packed bed reactor), the hydraulic retention time is 3 hours, and the dissolved oxygen is controlled at about 2.5mg / l. The sludge phase of the polymer is mixed, and the hydraulic retention time is 0.5 hours, and the underwater low-speed submersible mixer is used for mixing. The mixed liquid flowing out from the intracellular polymer denitrification tank enters the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com