Separation and coupling technology for multiphase catalytic reaction

A technology of reaction separation coupling and catalytic reaction, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems that do not involve industrial applications, and achieve saving equipment investment, energy consumption and The effect of operating cost, heat transfer reaction speed improvement, and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

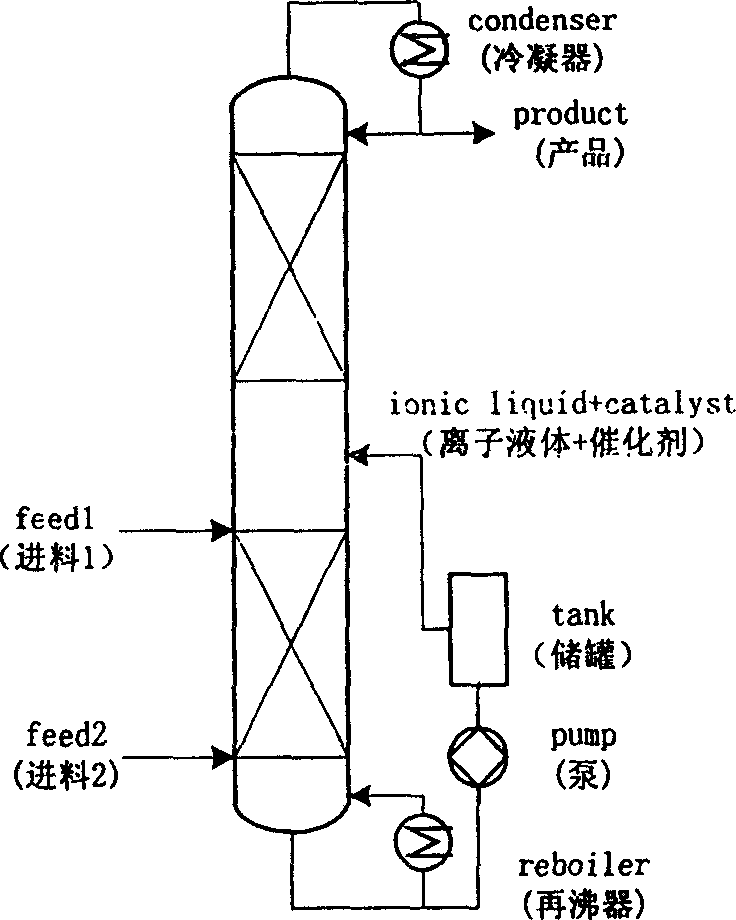

[0032] This example is the separation and production of butyl acetate by cyclic catalytic reaction, and the device is as attached Figure 5 As shown, it includes a glass packed tower, filled with glass beads, and a heating kettle is arranged at the bottom of the tower. Butanol and acetic acid are pumped in from the middle and lower part of the reaction section of the tower, with a molar ratio of 2:1, using [Bmim]BF 4 Ionic liquid, reaction kettle liquid temperature 130°C, tower top 20°C, continuous operation, composed of chromatographic analysis tower top product, calculated acetic acid conversion rate is 40%.

Embodiment 2

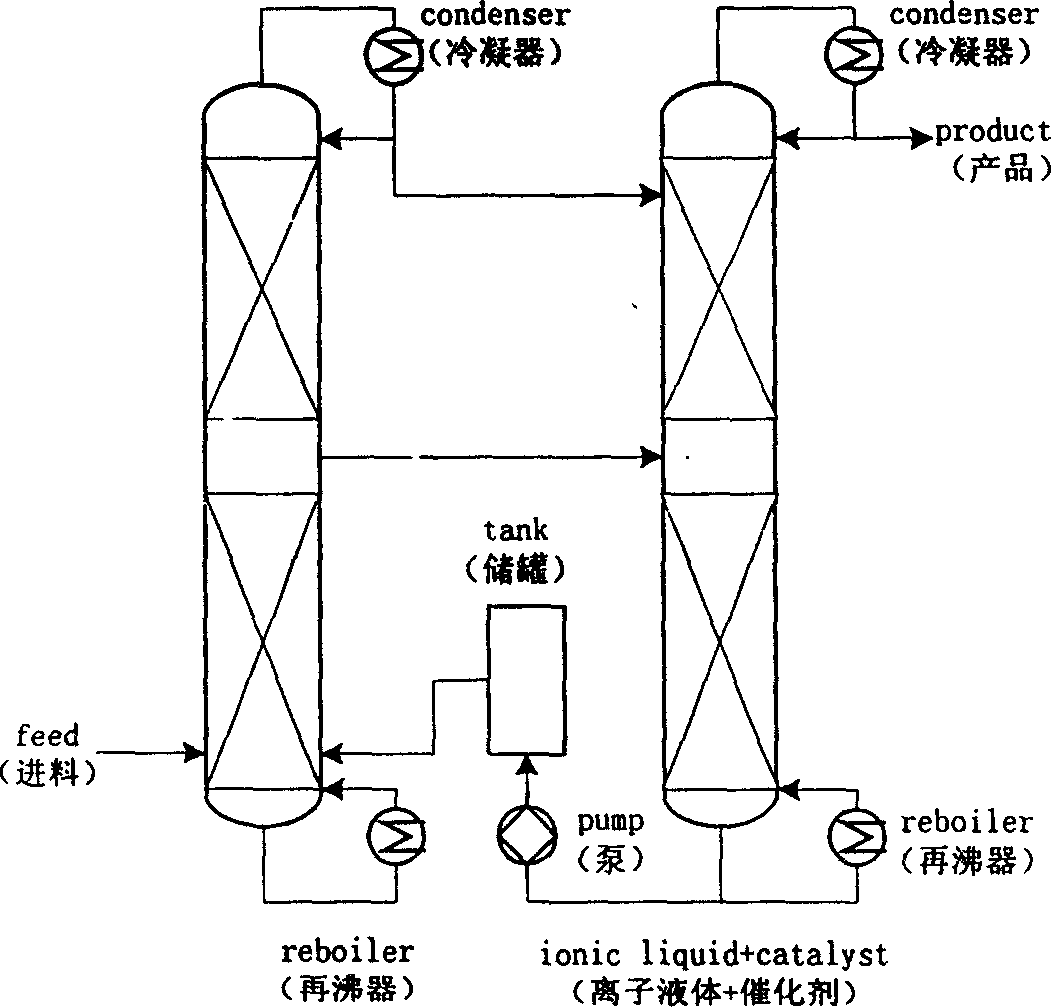

[0034] This example is the separation and production of methyl methacrylate (MMA) by cyclic catalytic reaction. The device is as attached Figure 6 As shown, it includes a glass packed tower, filled with glass beads, and a heating kettle is arranged at the bottom of the tower. Methanol and methacrolein are pumped in from the middle of the tower reaction section, the molar ratio is 8:3, and oxygen or oxygen-enriched air is fed in from the bottom of the tower, using [Bmim]PF 6 The ionic liquid is controlled at a proper temperature of the reactor liquid and the temperature of the tower top, and is continuously operated under reduced pressure. It is composed of chromatographic analysis of the tower top product, and the conversion rate of methacrolein is calculated to be 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com