Conductive paste and conductive film using it, plating method and production method for fine metal component

A conductive thin film, fine metal technology, used in semiconductor/solid-state device manufacturing, electrical components, conductive materials dispersed in non-conductive inorganic materials, etc., can solve through hole pattern deformation, mold damage, and fine metal components repeatability Reduce and other problems to achieve the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0247]

[0248] Titanium trichloride and sodium citrate were added to pure water to prepare a reducing agent solution, in which the concentrations of the two components adopted the values shown in Table 1 below:

[0249] Table 1

[0250] Component Concentration (mol / L)

[0251] Titanium trichloride 0.102

[0252] Sodium citrate 0.306

[0253] Ammonia water is then added to the reducing agent solution to adjust the pH of the reducing agent solution to 9 to 10 while maintaining its liquid temperature at 35°C.

[0254] Further, nickel chloride hexahydrate was added to pure water to prepare a solution in which the concentration of nickel chloride was 0.04 mol / L.

[0255] After adding 100 ml of reducing agent solution to 100 ml of this solution, as described above, followed by stirring at a temperature of 35° C. for one hour, the solid components precipitated in the solution were filtered, rinsed, and then dried to produce Ni powder .

[0256] When th...

example 2

[0274]

[0275] Nickel chloride hexahydrate and ferric chloride were added to pure water to prepare a solution in which the concentrations of the two components adopted the values shown in Table 2 below:

[0276] table 3

[0277] Component Concentration (mol / L)

[0278] Nickel chloride 0.008

[0279] Ferric chloride 0.032

[0280] To 100 ml of this solution was added 100 ml of the same reducing agent solution as used in Example 1, followed by stirring at 35° C. for one hour, and the solid component precipitated in the solution was filtered, rinsed, and then dried for Permalloy [Ni(20%)-Fe alloy] powder is produced.

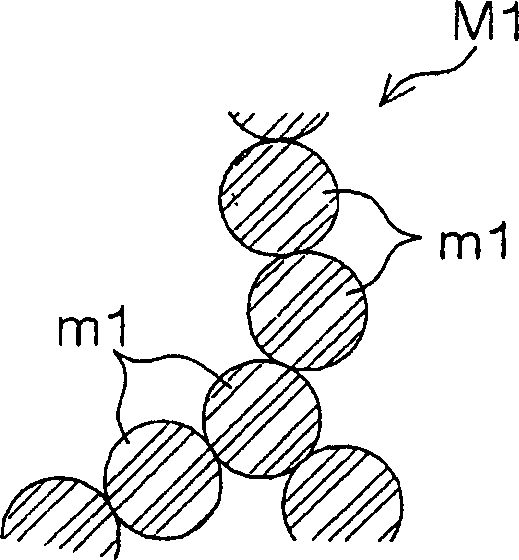

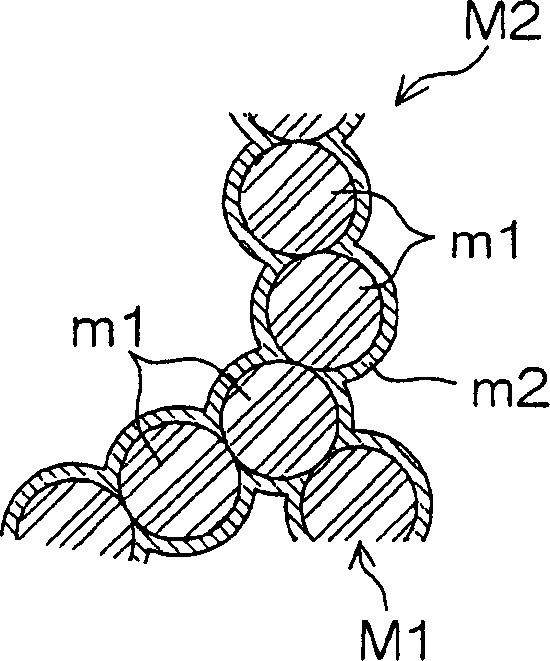

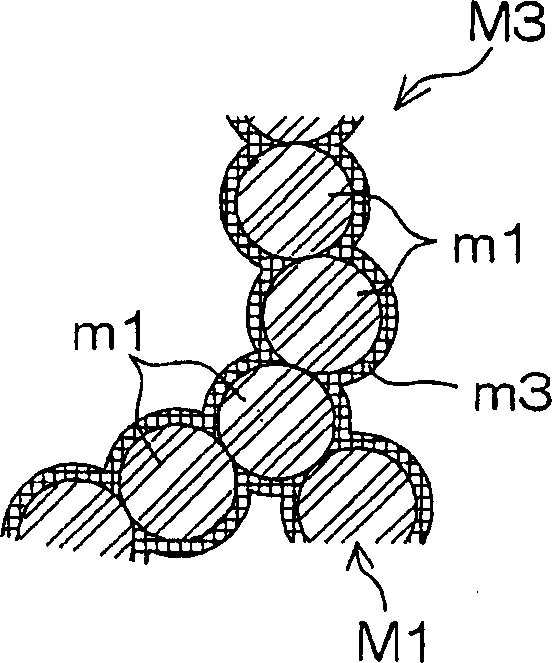

[0281] When the shape of the obtained permalloy powder was observed with a scanning electron microscope, as Figure 9 As shown, it was confirmed that the permalloy powder had the form of fine metal particles connected in a chain shape.

[0282] When the diameter of each metal particle and the chain diameter of the permalloy p...

example 3

[0291]

[0292] The same conductive paste as prepared in Example 1 was applied to one surface of the polyimide film used as a substrate so that the amount of solid content attached was 20 mg / cm 2 , and then apply a magnetic field with a strength of 79 A / m to the coating film along its plane and bake it at 100° C. for four hours to remove the solvent, thereby forming a conductive film.

[0293] In this conductive thin film, the chain-like Ni powder is oriented in the above-mentioned direction of the magnetic field, and has high electrical conductivity only in the direction of its in-plane orientation. That is, the volume resistivity in the direction of the orientation of the chain Ni powder in the plane of the conductive film exhibits 5×10 -5 The low value of Ω·cm, while the volume resistivity in the direction perpendicular to the orientation direction in the same plane is 3×10 -3 Ω·cm, while the volume resistivity in the thickness direction of the conductive film is 2.5×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com