Non-Oriented Electrical Steel Sheet Having Superior Magnetic Properties and a Production Method Therefor

a technology of non-oriented electrical steel and magnetic properties, which is applied in the direction of inorganic material magnetism, etc., can solve the problems of difficult cold rolling, reduced processing efficiency, and reduced life of molds, and achieve excellent magnetic properties, increase the distribution density of coarse inclusions, and enhance the growth of grains and the mobility of domain walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0098]Vacuum melting was performed in a laboratory, thus preparing steel ingots having the components shown in Table 1 below. As such, the amount of each of impurity elements C, S, N, Ti was controlled to 0.002%, and 0.3˜0.5% of Al was added to molten steel to facilitate the formation of inclusions, after which the remainder of Al, and Si and Mn were added thus making steel ingots. Each of the ingots was heated to 1,150° C., and finish hot rolled at 850° C. thus manufacturing a hot rolled sheet having a thickness of 2.0 mm. The hot rolled sheet was annealed at 1,050° C. for 4 min and then pickled. Subsequently, cold rolling was conducted so that the thickness of the sheet was 0.35 mm, followed by carrying out final annealing at 1,050° C. for 38 sec.

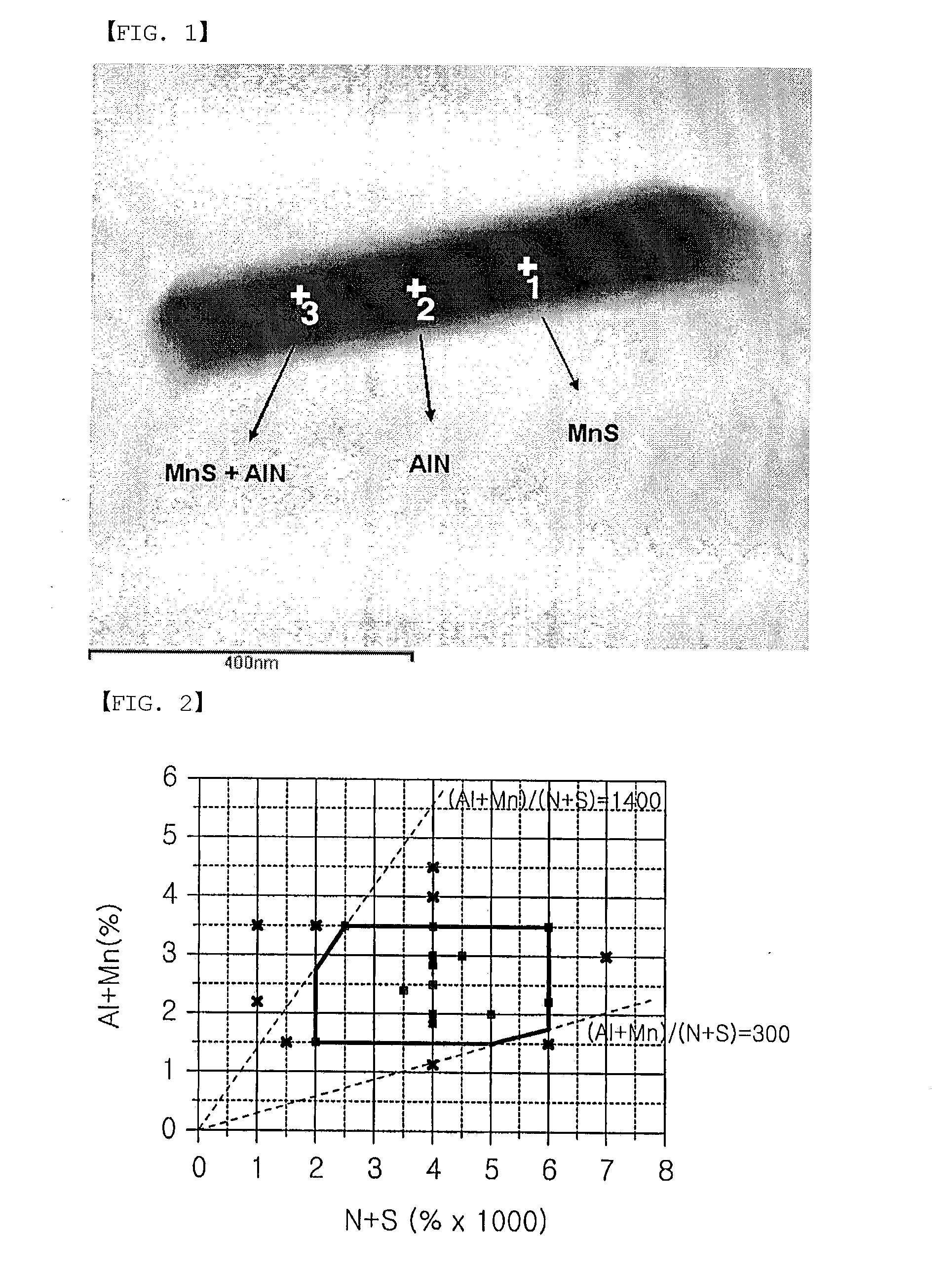

[0099]The size and distribution density of inclusions of respective sheets, the core loss, the magnetic flux density and hardness were measured. The results are shown in Table 2 below. A sample for use in observing the inclusions was manu...

example 2

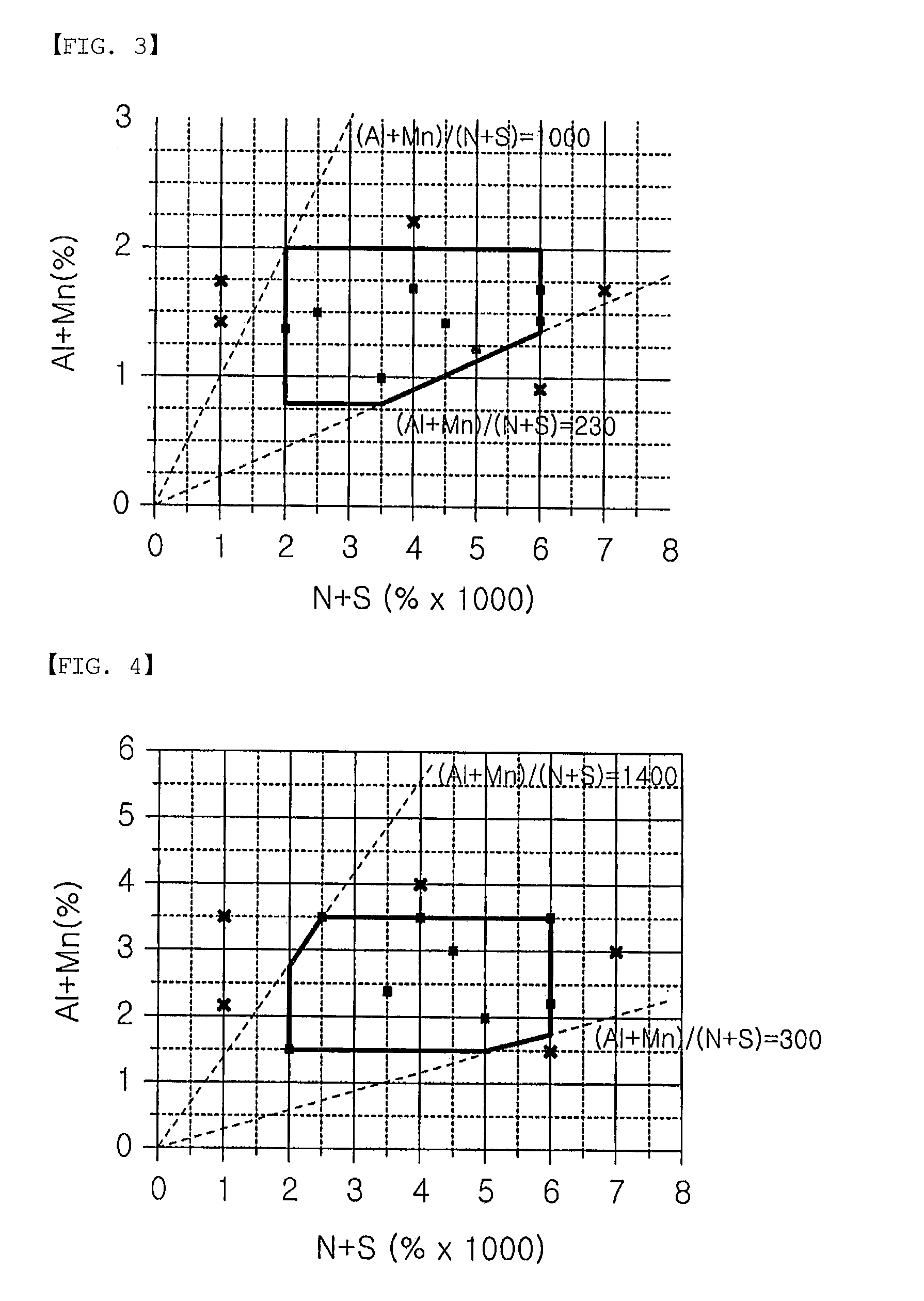

[0102]Vacuum melting was performed in a laboratory, thus preparing steel ingots having the components shown in Table 3 below. As such, the components of steel were controlled while variously adjusting the amounts of impurity elements N and S, and 0.3˜0.5% of Al was added to molten steel to facilitate the formation of inclusions, after which the remainder of Al, and Si and Mn were added thus making steel ingots. Each of the ingots was heated to 1,1500, and finish hot rolled at 850° C. thus manufacturing a hot rolled sheet having a thickness of 2.0 mm. The hot rolled sheet was annealed at 1,050° C. for 4 min and then pickled. Subsequently, cold rolling was conducted so that the thickness of the sheet was 0.35 mm, followed by carrying out final annealing at 1,050° C. for 38 sec.

[0103]The size and distribution density of inclusions of respective sheets, the core loss, the magnetic flux density and hardness were measured. The results are shown in Table 4 below. A sample for observing the...

example 3

[0106]Vacuum melting was performed in a laboratory, thus preparing steel ingots having the components shown in Table 5 below. As such, 0.3˜0.5% of Al was added to molten steel to facilitate the formation of inclusions, after which the remainder of Al, and Si, Mn and P were added thus making steel ingots. Each of the ingots was heated to 1,150° C., and finish hot rolled at 850° C. thus manufacturing a hot rolled sheet having a thickness of 2.0 mm. The hot rolled sheet was annealed at 1,050° C. for 4 min and then pickled. Subsequently, cold rolling was conducted so as to form sheets having different thicknesses in the range of 0.15˜0.35 mm, followed by carrying out final annealing at 1,050° C. for 38 sec. The core loss and magnetic flux density of respective sheets having different thicknesses were measured. The results are shown in Table 6 below. A sample for observing the inclusions was manufactured using a replica method that is typical in the steel industry, and a transmission ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com