Anti methanol toxication platinum bismuth catqalyst and its preparation method

A bismuth catalyst, catalyst technology, applied in electrical components, battery electrodes, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

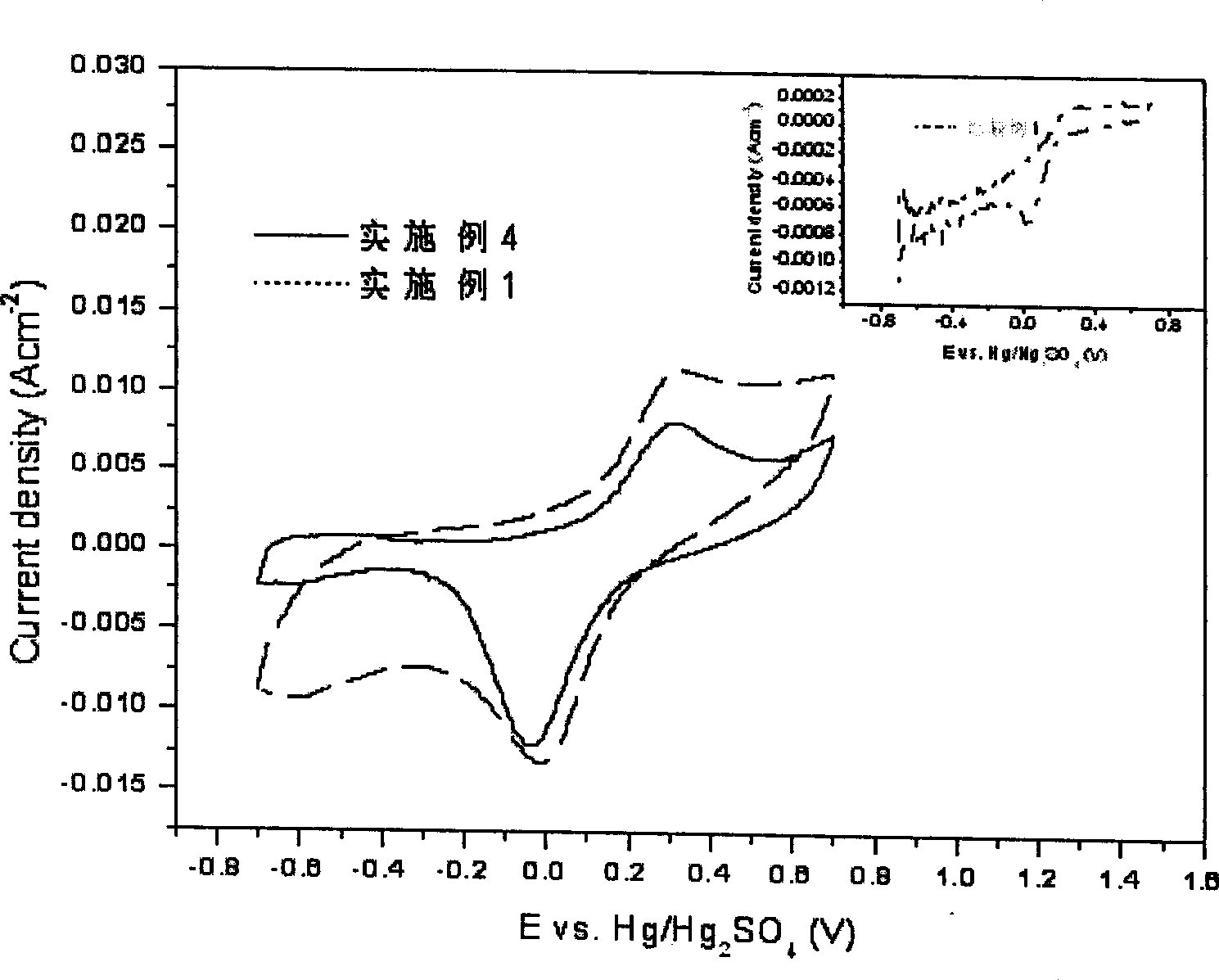

Image

Examples

Embodiment 1

[0020] Mix metal Pt powder with a purity of 99.99% and metal Bi powder with a molar ratio of 1:1 in an agate mortar and transfer them to a cylindrical bearing steel mold with a diameter of 10 mm. Apply a pressure of 10MPa on the desktop electric tablet press produced by the company for cold rolling, and hold the pressure at 10MPa for 100 seconds to obtain a block.

[0021] Put the cylindrical block into a quartz tube with a diameter of 12 mm, and seal the quartz tube after evacuating for 15 minutes. The quartz tube with the sample sealed was put into a heating furnace, and melted at 800°C, and this was repeated 4 times. After the sample is completely cooled, it is taken out, and a bulk platinum-bismuth catalyst is obtained without heat treatment.

Embodiment 2

[0023] Mix metal Pt powder with a purity of 99.99% and metal Bi powder with a molar ratio of 1.5:1 in an agate mortar, and transfer them all to a cylindrical bearing steel mold with a diameter of 10 mm. Apply a pressure of 10 MPa on the desktop electric tablet press produced by the technology company for cold rolling, and hold the pressure for 100 seconds under the pressure of 10 MPa to obtain a cylindrical block.

[0024] Put the cylindrical block into a quartz tube with a diameter of 12 mm, and seal the quartz tube after evacuating for 15 minutes. The quartz tube with the sample sealed was put into a heating furnace, and melted at 800°C, and this was repeated 4 times. Heat treatment at 700° C. for 48 hours to obtain a bulk platinum-bismuth catalyst.

Embodiment 3

[0026]Mix metal Pt powder with a purity of 99.99% and metal Bi powder with a molar ratio of 2:1 in an agate mortar, and transfer them all to a cylindrical bearing steel mold with a diameter of 10 mm. Apply a pressure of 15 MPa on the desktop electric tablet press produced by the technology company for cold rolling, and hold the pressure for 100 seconds under the pressure of 15 MPa to obtain a cylindrical block.

[0027] Put the cylindrical block into a quartz tube with a diameter of 12 mm, and seal the quartz tube after evacuating for 15 minutes. The quartz tube with the sample sealed was put into a heating furnace, and melted at 900°C, and this was repeated 3 times. Heat treatment at 600° C. for 240 hours to obtain a bulk platinum-bismuth catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com