Metal organic compound vapor deposition device for the growth of zinc oxide semiconductor film

An organic compound, vapor deposition technology, used in semiconductor/solid-state device manufacturing, crystal growth, single crystal growth and other directions, can solve problems such as difficulty in obtaining p-type doping sources, reducing the quality of crystal films, and unsolved problems, achieving real-time Effective nitrogen doping, good laminar flow, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

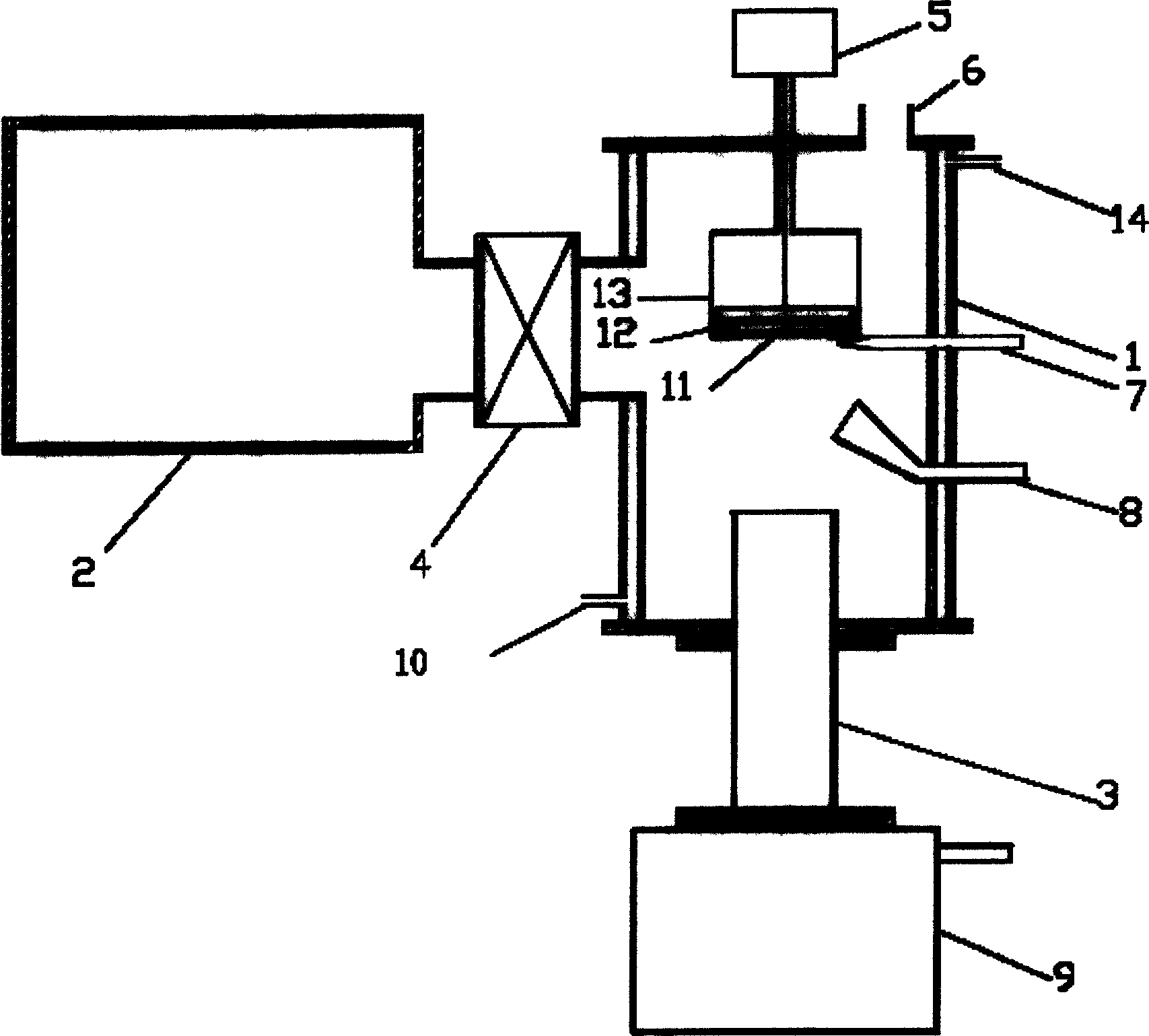

[0011] refer to figure 1 The metal-organic compound vapor deposition device for growing zinc oxide semiconductor thin films of the present invention includes a growth chamber 1, a sampling chamber 2, a movable shutter 4 connecting the growth chamber and the sampling chamber, and an atomic generator for activating cracked nitrogen source gas. 9, the air outlet pipe 3 of the atomic generator 9 is placed in the growth chamber 1, the growth chamber adopts a water-cooled structure, has a double wall, the outer wall has a water inlet 10 and a water outlet 14, and the interlayer is filled with cooling water for cooling, which can avoid the growth of the inner wall. The reaction on the substrate can increase the temperature gradient of the gas around the substrate and reduce the uniform gas phase reaction. The growth chamber is provided with a horizontal sample rack 13 driven by a motor 5, a sample heater 12, an oxygen source intake pipe 7, a zinc source intake pipe 8, and an exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com