Drip irrigation pipe head binding method

A bonding method and drip irrigation pipe technology, which are applied in the fields of botany equipment and methods, climate change adaptation, gardening, etc., can solve the problems of high defective rate, difficult to control, and the dripper has not been preheated, so as to improve the pressure bearing. Strength, productivity and bond strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

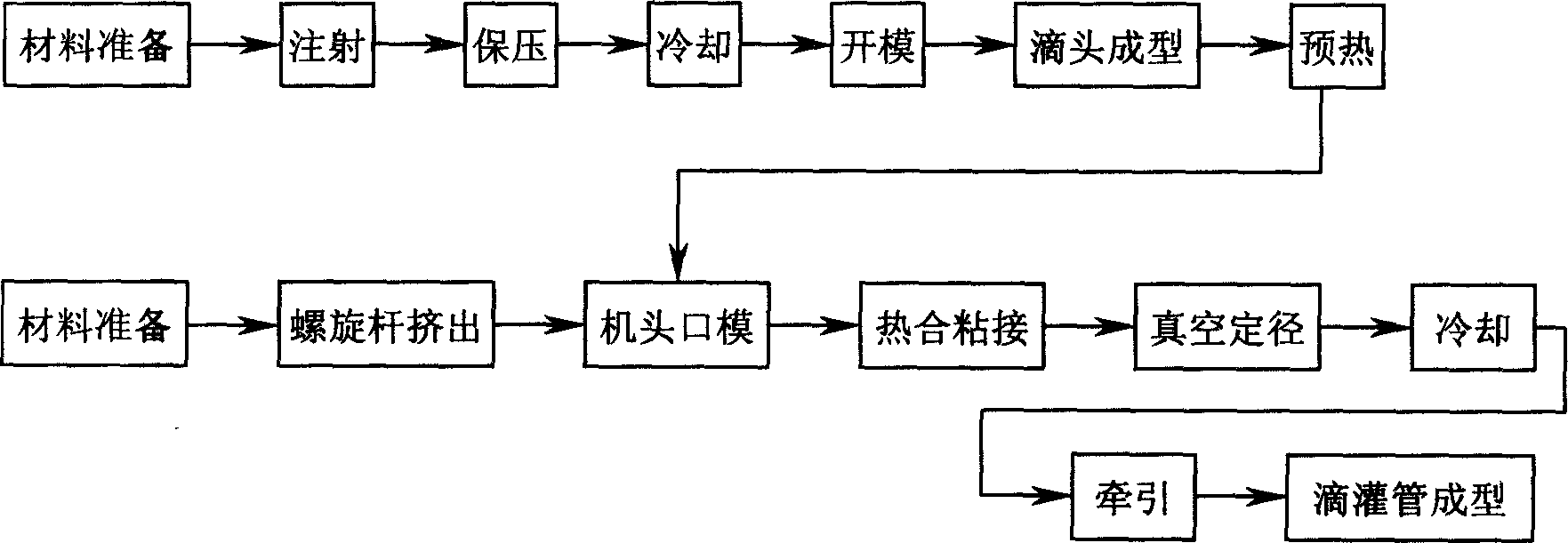

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

[0008] According to the technical scheme, the material formula and method steps are:

[0009] 1. Material preparation: The selection of dripper and tube embryo material is the basis of the processing technology, that is, the material must not only meet the performance of the product, the injection molding (extrusion) processing technology, but also meet the bonding processing technology. Therefore, (1) The dripper material should have certain strength and hardness, and it should also be suitable for the processing technology of injection molding. Its melt index is 6-8, and the material formula is high pressure polyethylene: low pressure polyethylene: medium density polyethylene = 2 : 6: 2; tube embryo material should have a certain degree of flexibility to meet the extrusion process, its melt index is 6 ~ 8, the material formula is high pressure polyethylene: linear po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com