Underwater epoxy resin grouting material

An epoxy resin grouting and liquid epoxy resin technology, which is applied in the field of underwater epoxy resin grouting materials, can solve the problems of high surface tension and contact angle of the slurry, water conditions that cannot be applied to the slurry material, and low wetting and wetting ability. , to achieve the effect of excellent wetting performance, low curing shrinkage and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1 (formulation number CW1):

[0014] 100 parts by weight of bisphenol A type liquid epoxy resin with an epoxy value of 0.52

[0015] Acetone 40 parts by weight

[0016] 40 parts by weight of furfural

[0017] 20 parts by weight of phenol formaldehyde hexamethylenediamine condensation product

Embodiment 2

[0019] Embodiment 2 (formulation number CW2):

[0020] 100 parts by weight of bisphenol A type liquid epoxy resin with an epoxy value of 0.53

[0021] Acetone 40 parts by weight

[0022] 40 parts by weight of furfural

[0023] 40 parts by weight of phenol-formaldehyde m-phenylenediamine condensation product

[0024] 3 parts by weight of silane coupling agent

[0025] Mix the above formula evenly to obtain the underwater epoxy resin grouting material of the present invention.

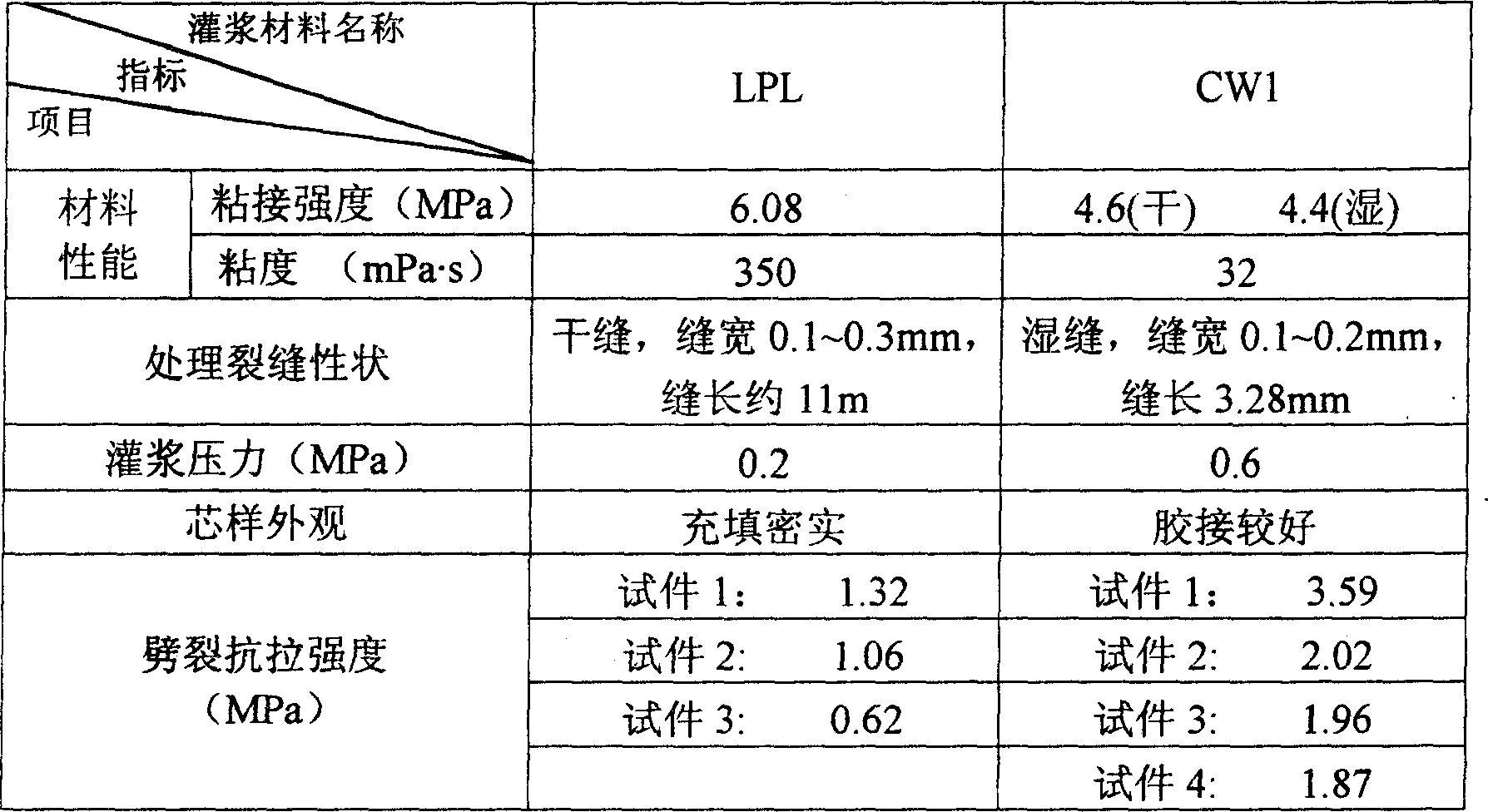

[0026] Tables 1 to 4 have shown the experimental results of the underwater epoxy resin grouting material of the present invention, by the analysis of these experimental results it can be known that:

[0027] Compared with similar domestic slurry materials, this slurry material is mainly hydrophobic and hydrophilic. It uses slurry to drain water and abandons acetone pilot grouting. It saves labor and materials, is beneficial to environmental protection, and ensures project quality. Three Gorges Proje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com