Detaching type polymer/montmorillonite composite material and preparing method thereof

A nano-composite material and montmorillonite technology, which is applied in the field of preparation of exfoliated polymer/montmorillonite nano-composite materials, can solve the problem of weakening the interaction between polymer and montmorillonite, increasing the density of modifier, and adversely affecting montmorillonite. Soil dispersion and other problems, to achieve the effect of easy promotion, quick effect, and low production input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

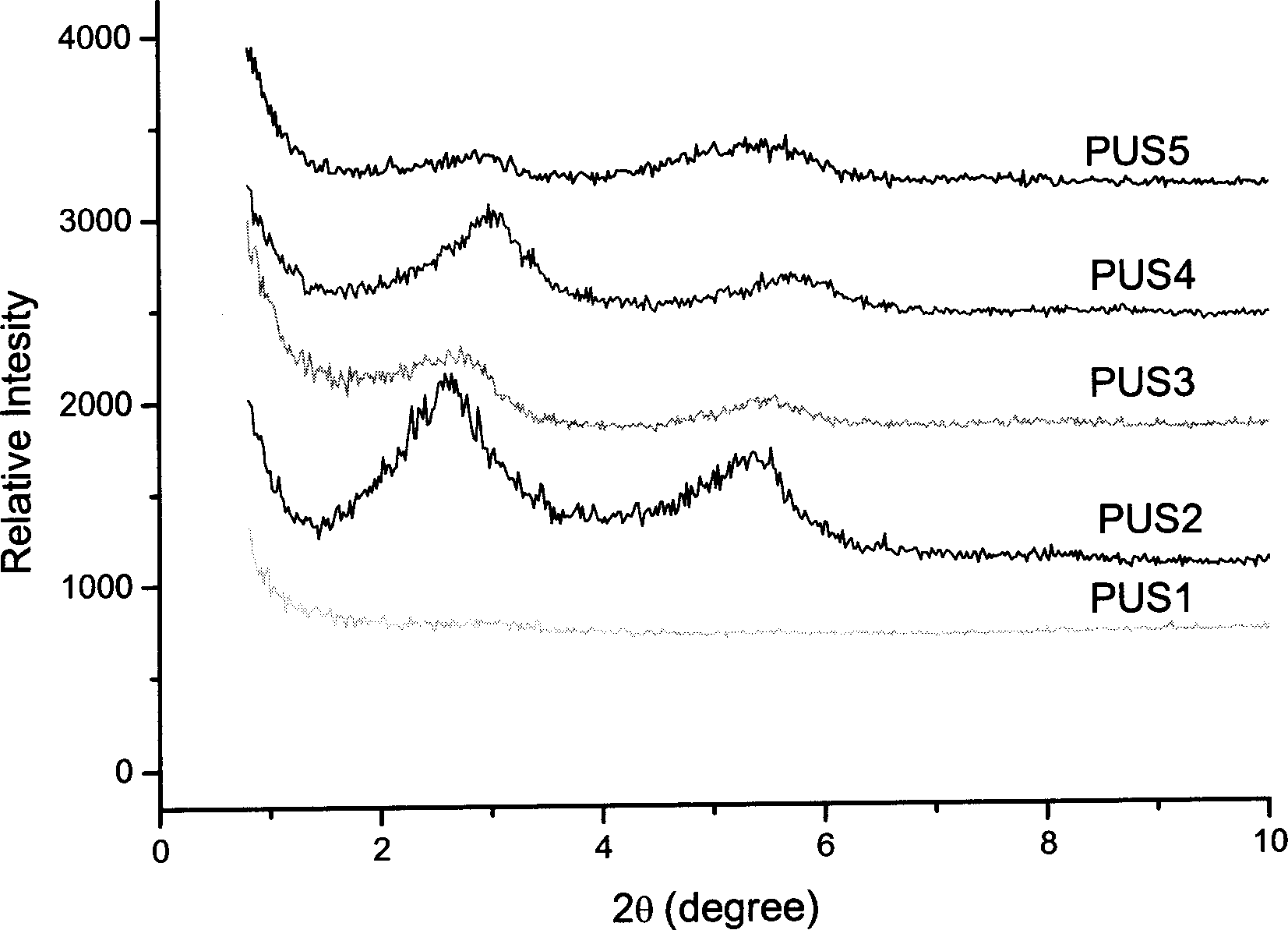

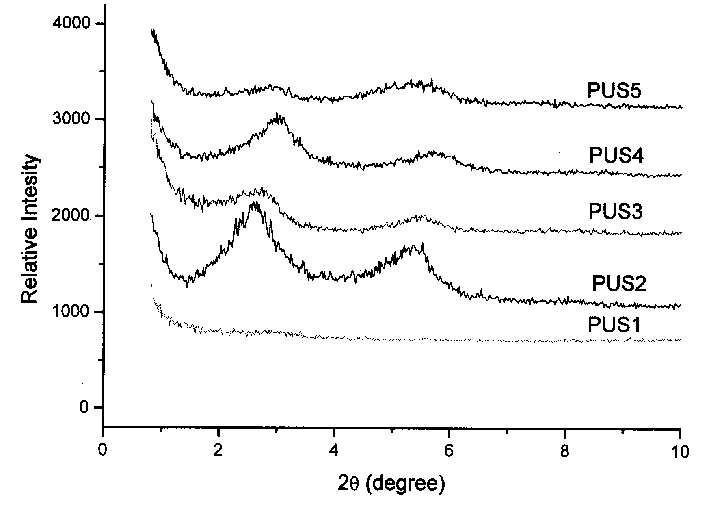

[0012] 24 grams of montmorillonite with a cation exchange capacity of 120meq / 100g was stirred in 500ml of deionized water at high speed for 0.5h to form a stable suspension system. Add 17.3 grams of cation exchanger octadecylamine to 500 ml of deionized water, add equimolar protonating agent hydrochloric acid, and emulsify at a high speed to form a uniformly dispersed emulsion. The suspension and emulsion heated to 60° C. were mixed under high-speed stirring for 10 minutes, precipitated, filtered, vacuum-dried and pulverized to obtain organic montmorillonite (OM1). Melt intercalation of polyurethane and organic montmorillonite in traditional polymer mixing or extrusion equipment to directly obtain polymer / montmorillonite nanocomposite PUS1, its wide-angle X-ray results (see attached table 1) It shows that PUS1 has an exfoliated structure. Change the dosage of cation exchanger to be 1.0CEC, 1.5CEC, 2.0CEC, 2.5CEC respectively, namely respectively 28.8 grams, 43.2 grams, 57.6 g...

Embodiment 2

[0025] 40 grams of montmorillonite with a cation exchange capacity of 50 meq / 100 g was stirred in 1000 ml of deionized water at high speed for 1 hour to form a stable suspension system. Add 12 grams of cation exchanger cetyltrimethylammonium bromide into 200 ml of deionized water, add equimolar protonating agent sulfuric acid, and emulsify at high speed to form a uniformly dispersed emulsion. The suspension and emulsion heated to 80° C. were mixed under high-speed stirring for 30 minutes, precipitated, filtered, vacuum-dried and pulverized to obtain organic montmorillonite. Melt intercalation of polyamide 6 and organic montmorillonite in traditional polymer mixing or extrusion equipment to directly obtain polymer / montmorillonite nanocomposites, the (001 ) diffraction peaks disappear, indicating that montmorillonite is well dispersed in these polymers and has an exfoliated structure.

Embodiment 3

[0027] 16 grams of montmorillonite with a cation exchange capacity of 150 meq / 100 g was stirred in 1000 ml of deionized water at high speed for 2 hours to form a stable suspension system. Add 14.4 grams of cation exchanger cetyltrimethylammonium bromide to 300 ml of deionized water, add equimolar protonating agent sulfuric acid, and emulsify at high speed to form a uniformly dispersed emulsion. The suspension and emulsion heated to 90° C. were mixed under high-speed stirring for 60 minutes, precipitated, filtered, vacuum-dried and pulverized to obtain organic montmorillonite. Melt intercalation of polyamide 66 and organic montmorillonite in traditional polymer mixing or extrusion equipment to directly obtain polymer / montmorillonite nanocomposites, the (001 ) diffraction peaks disappear, indicating that montmorillonite is well dispersed in these polymers and has an exfoliated structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com