Aromatic liquid crystal polyester and its film

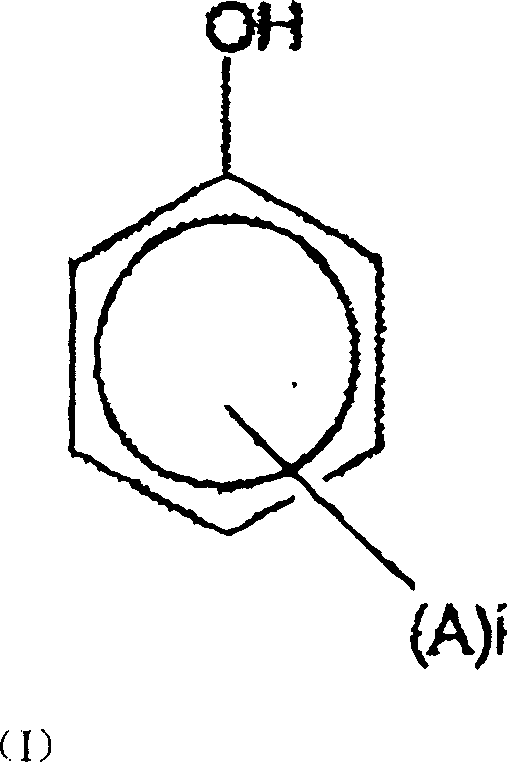

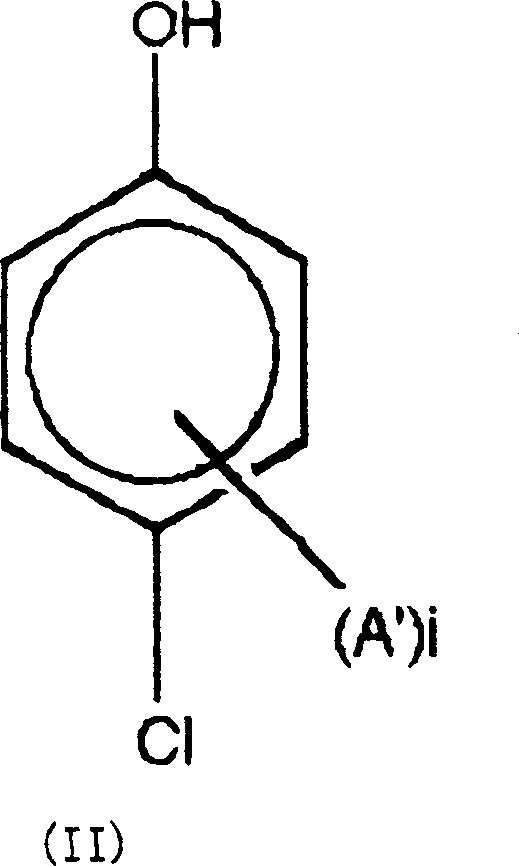

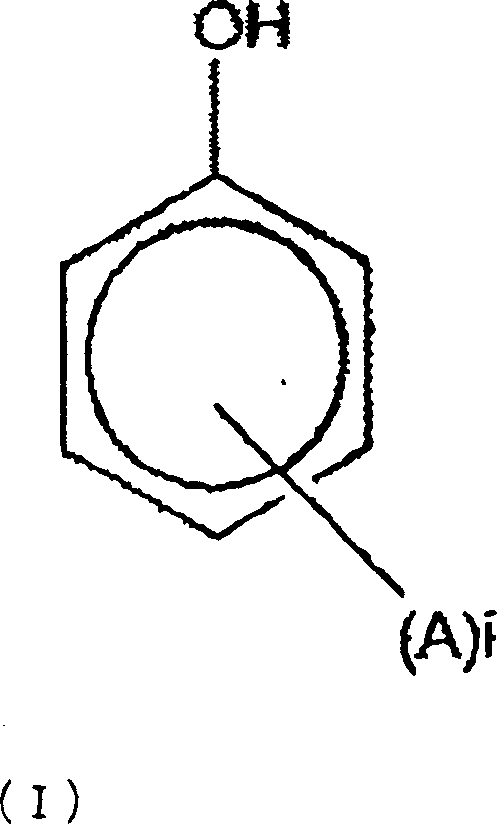

A liquid crystal polyester and aromatic technology, which can be used in liquid crystal materials, other household appliances, electronic equipment, etc., and can solve problems such as deterioration of electrode materials and insufficient dielectric loss of dielectric films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0115] The method for preparing the dielectric paste of the present invention is not particularly limited, and includes a method of dissolving an aromatic liquid crystal polyester in a solvent to obtain an aromatic polyester solution, and adding dielectric powder or the like to the solution.

[0116] A dielectric film can be obtained by coating the dielectric paste of the present invention on a substrate.

[0117] Specifically, if necessary, the dielectric paste of the present invention is filtered with a filter or the like to remove fine impurities contained in the dielectric paste, and then coated on a substrate, and the solvent is removed to obtain a dielectric film.

[0118] Regarding the viscosity of the dielectric paste to be used, the appropriate viscosity varies depending on the coating method, but is preferably 0.1 poise to 200 poise, more preferably 0.5 poise to 30 poise.

[0119] The coating method is not particularly limited, and known methods such as spin coating,...

manufacture example 1

[0133] Add 752.72g (4.00 moles) of 2-hydroxyl-6-naphthoic acid, 220.22g (2.00 moles) of hydroquinone, 2, 432.38 g (2.00 mol) of 6-naphthalene dicarboxylic acid, 986.19 g (9.2 mol) of acetic anhydride, and 0.143 g of 1-methylimidazole as a catalyst were stirred at room temperature for 15 minutes, and then the temperature was raised while stirring. After internal temperature reached 145 degreeC, it stirred for 1 hour, maintaining the same temperature.

[0134] Next, while distilling off distilled by-product acetic acid and unreacted acetic anhydride, the temperature was raised from 145° C. to 310° C. over 3 hours. Then, 1.427 g of 1-methylimidazole was further added, and the temperature was maintained at the same temperature for 30 minutes to obtain an aromatic polyester. The obtained aromatic polyester was cooled to room temperature, and pulverized with a pulverizer to obtain an aromatic polyester powder (particle diameter: about 0.1 mm to about 1 mm).

[0135] The powder obt...

manufacture example 2

[0137] 191.8 g (1.02 moles) of 2-hydroxyl-6-naphthoic acid, 4,4'-dihydroxybiphenyl 63.3 g (0.34 mole), isophthalic acid 56.5 g (0.34 mole) and acetic anhydride 191 g (1.87 mole). After fully substituting the inside of the reaction vessel with nitrogen, the temperature was raised to 150°C over 15 minutes under nitrogen flow, and the temperature was maintained, and refluxed for 3 hours.

[0138] Thereafter, while distilling off distilled by-product acetic acid and unreacted acetic anhydride, the temperature was raised to 320° C. over 170 minutes, and the reaction end point was when the torque was confirmed to increase, and the contents were taken out. The obtained solid was cooled to room temperature, pulverized with a coarse pulverizer, and kept at 250° C. for 10 hours under a nitrogen atmosphere to conduct a polymerization reaction in the solid phase. The obtained aromatic liquid crystal polyester was dissolved in p-chlorophenol, and the intrinsic viscosity was measured at 60°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com