Lucid ganoderma spore powder polysaccharide, production method and use

A technology of Ganoderma lucidum spore powder and production method, which are applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, organic active ingredients, etc., can solve problems such as unreported, and achieve enhanced immune activity, simple extraction and separation method, and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Soak 100 g of dried Ganoderma lucidum spore powder softened by microwave at room temperature for 24 hours with 1 liter of deionized water, and filter. The filtrate was concentrated under reduced pressure at 50°C to 200-300 ml. Then precipitate with 95% ethanol, the final concentration of ethanol is 85%, and precipitate for 24 hours. Centrifuge, dissolve the precipitate with 200-300 ml of water, centrifuge, and dialyze with deionized water for 48-72 hours. Concentrate under reduced pressure at 50°C and freeze-dry to obtain 1.5 g of total sugar LzPS of Ganoderma lucidum spores with a purity of 69%.

Embodiment 2

[0037]100 g of dried Ganoderma lucidum spore powder softened by microwaves was boiled with 1 liter of deionized water at 80-90° C. for 1 hour, and filtered. The filtrate was concentrated under reduced pressure at 50°C to 200-300 ml. Then precipitate with 95% ethanol, the final concentration of ethanol is 85%, and precipitate for 24 hours. Centrifuge, dissolve the precipitate with 200-300 ml of water, centrifuge, and dialyze with deionized water for 48-72 hours. Concentrate under reduced pressure at 50°C and freeze-dry to obtain 2.1 g of total sugar LzPS of Ganoderma lucidum spores with a purity of 67%.

Embodiment 3

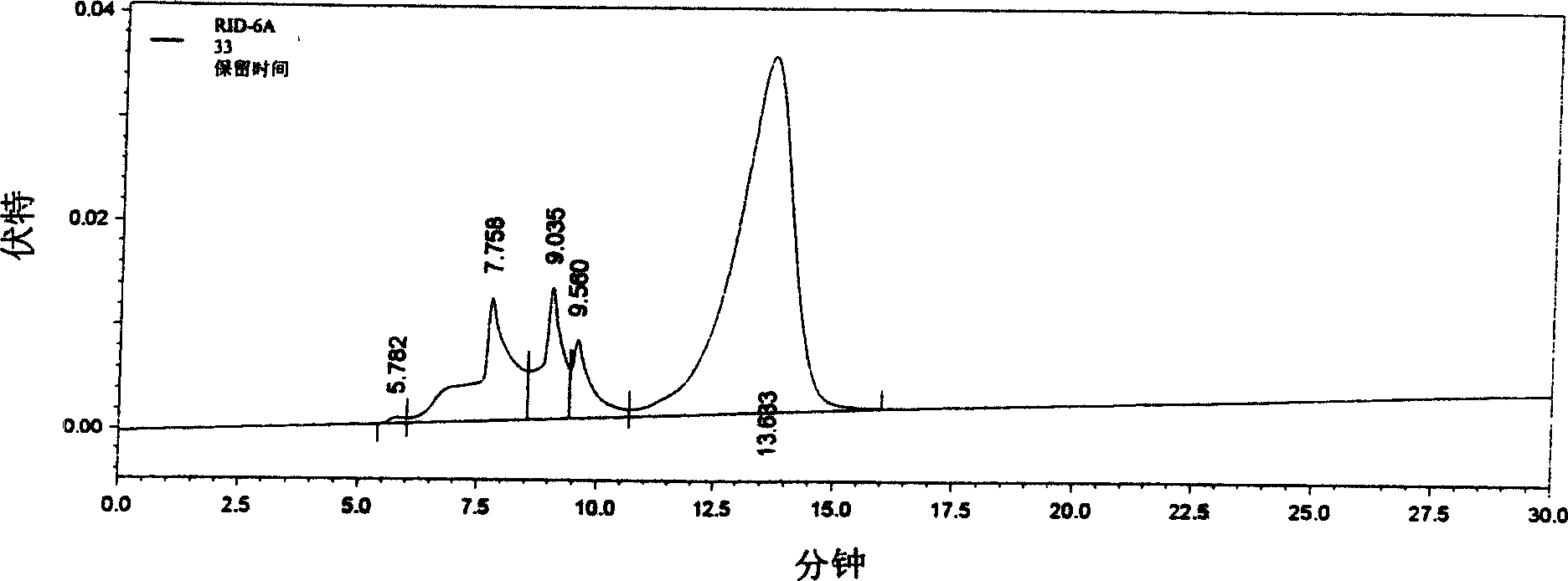

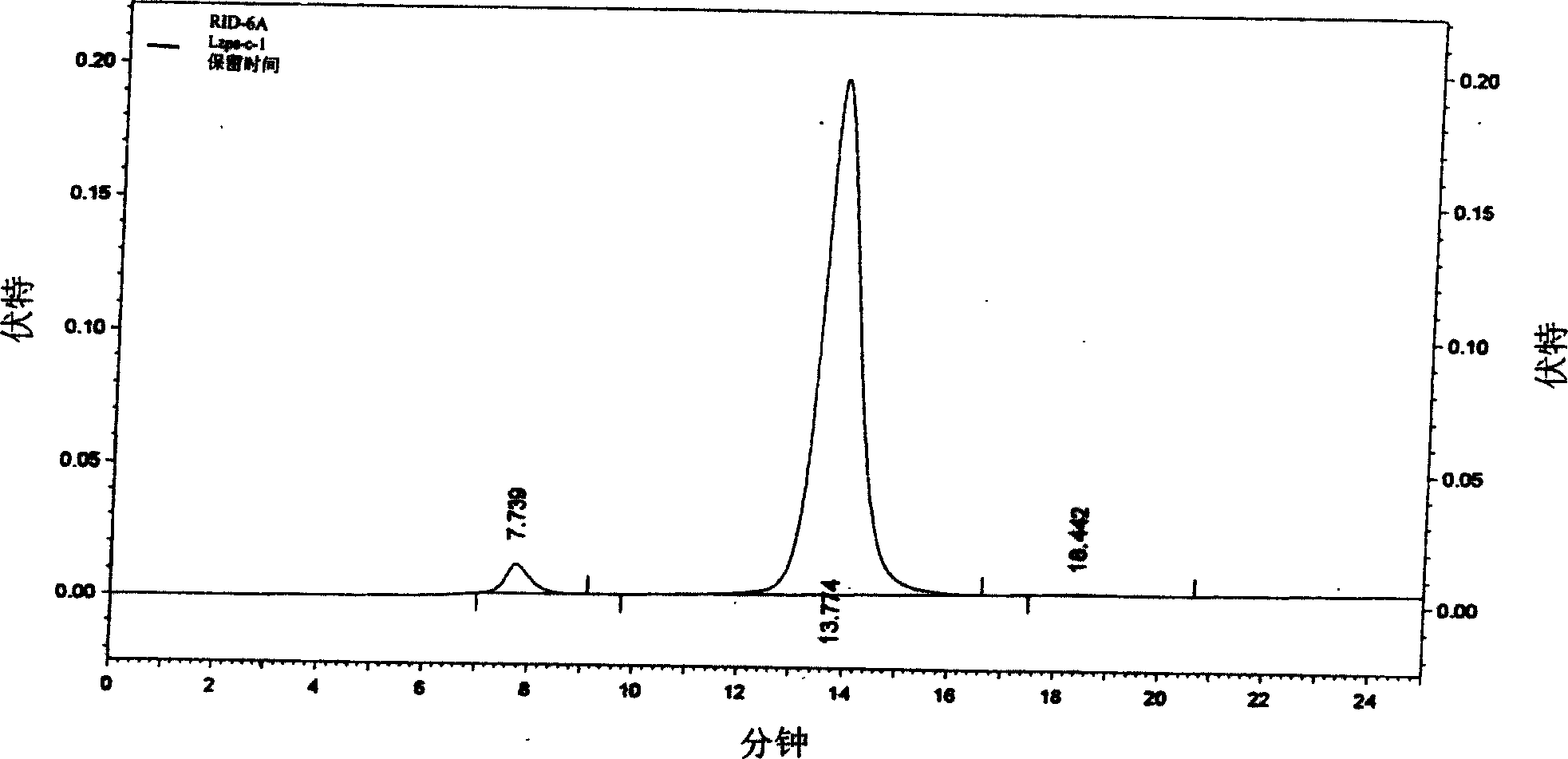

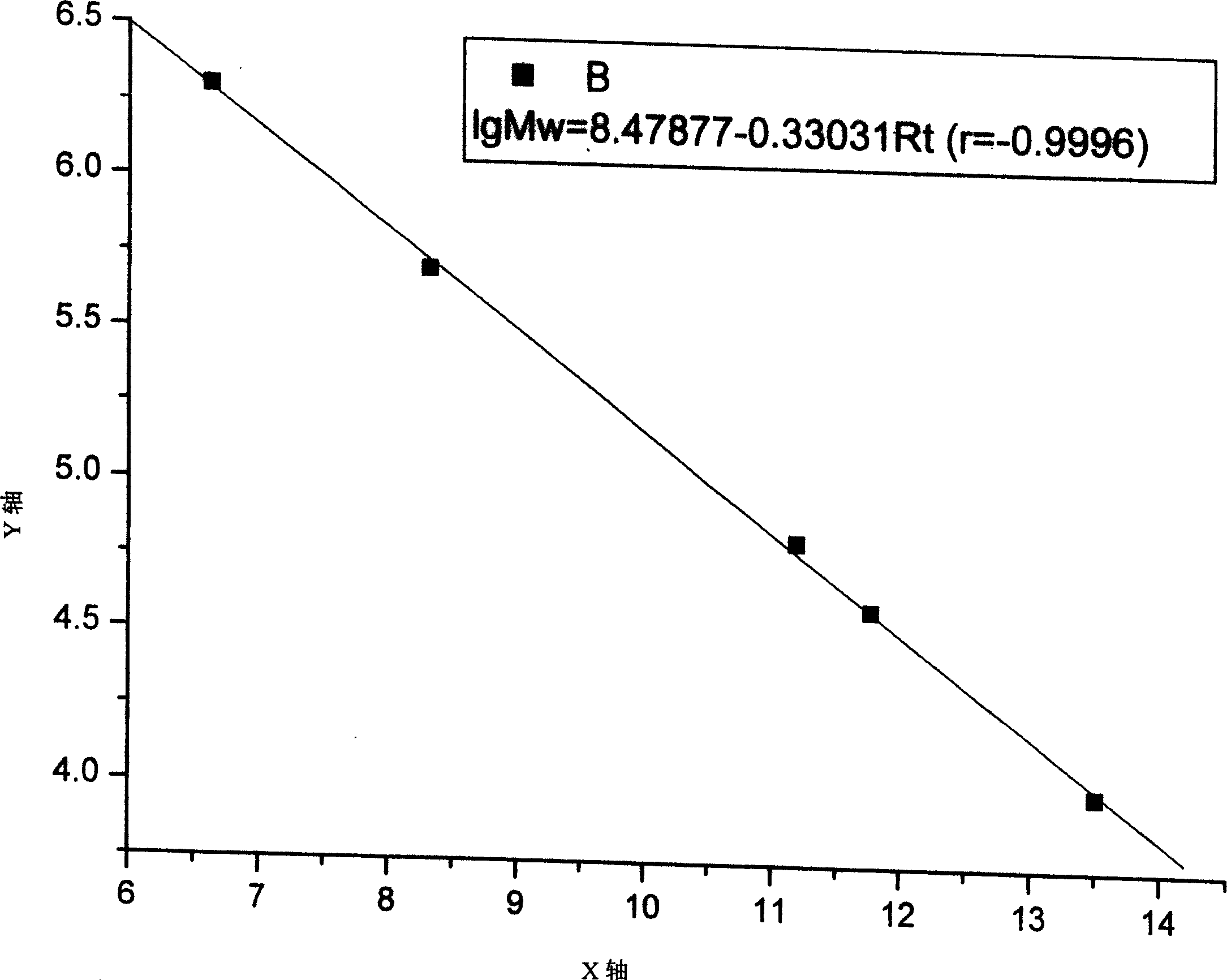

[0039] Add 150 ml of water to dissolve Ganoderma lucidum spore total sugar LzPS, add 2 times of 95% ethanol under stirring, overnight, centrifuge and dissolve the precipitate in 50 ml of water, dialyze with deionized water for 24 hours, centrifuge, concentrate under reduced pressure, freeze-dry Obtain the first fraction LzPS-a 0.26g with a purity of 68%, add 3 times of 95% ethanol to the supernatant and process the same as above to obtain the second fraction LzPS-b 0.20g with a purity of 76%, add 5 times of 95% ethanol to the supernatant The third fraction LzPS-c 0.21g with a purity of 70% was obtained by the same treatment as above, and the supernatant was added with 7 times of 95% ethanol to obtain the fourth fraction LzPS-d 0.18g with a purity of 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com