Explosion proof method of close region of explosion

A near area, explosion-proof box technology, applied in the direction of blasting, aircraft parts, aircraft indicating devices, etc., can solve the problems of high cost, inconvenient use of explosion-proof measures, etc., achieve light weight, small size, and solve the limitations of the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

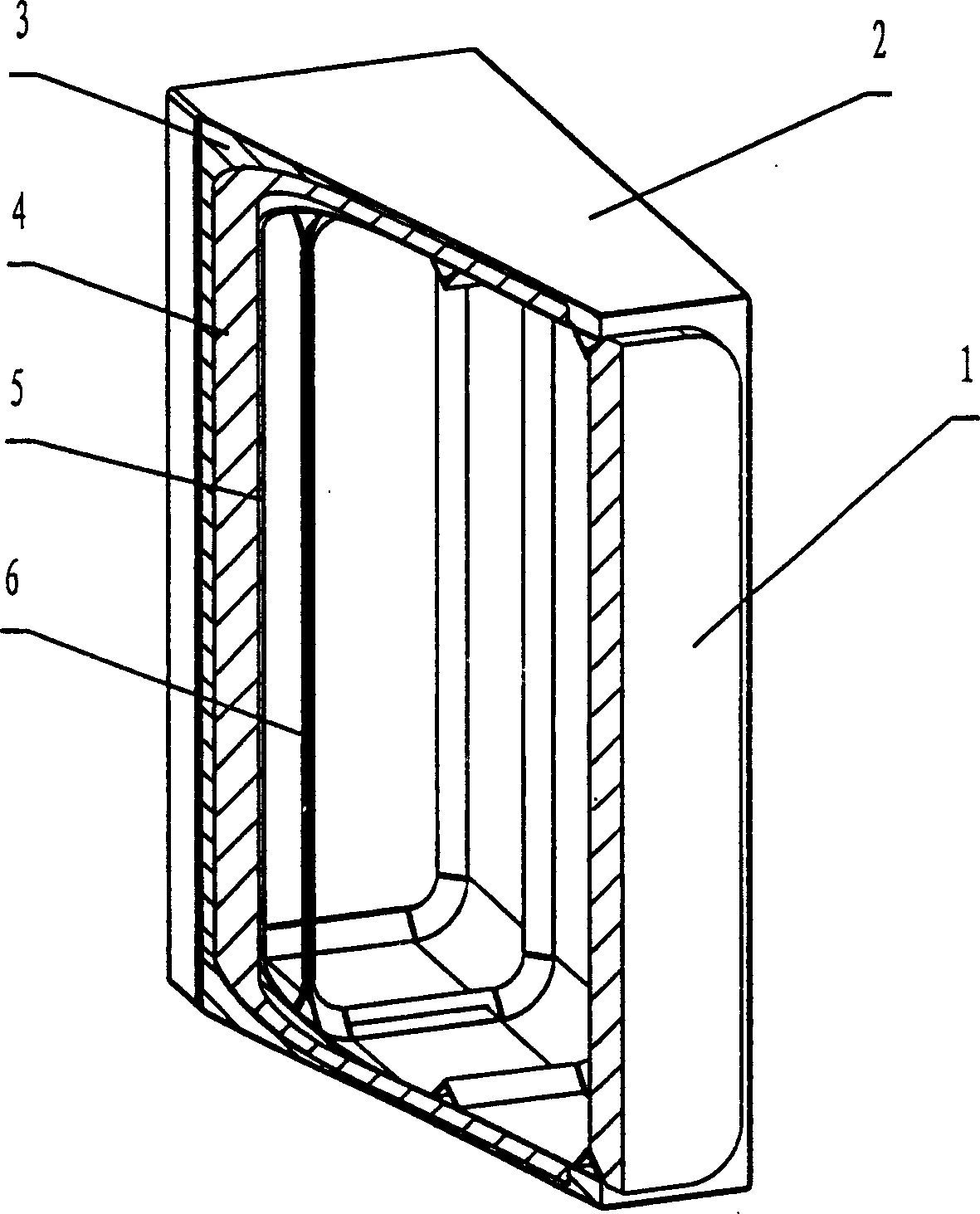

[0027] refer to figure 1 , the explosion-proof method that the present invention can be used in such an explosion near area of the civil aviation cabin is described in detail:

[0028] 1. Prepare in advance the components of the explosion-proof box used in the near area of the explosion (such as figure 1 shown), placed at the predetermined position, the parts include:

[0029] (1) adopting a metal plate with a thickness of 1mm-4mm to make the shell 5, which is in the shape of a square tube with two ends open, with a length of 800mm, a width of 215mm, and a height of 660mm;

[0030] (2) mining thickness is that 20 millimeters of closed-cell polyurethane materials make a porous material layer 3, and its shape is the square tube shape of two ends opening, and its length is 800 millimeters, and width is 220 millimeters, and height is 680 millimeters; Better tensile strength, larger elongation thickness is 25 millimeters of rubber to make a lightweight material layer 4, and i...

Embodiment 2

[0037] Such as figure 1 Shown, on the basis of embodiment 1, increase a step (4) adopt 0.5 millimeter thick aluminum plate to make a height be 750 millimeters, width is 305 millimeters, the decorative shell 2 that length is 800 millimeters, and this shell is enclosed within Outside the porous material layer 3, it is positioned at the outermost layer of the box body. It is usually used as a dining car in the aviation cabin. It is beautiful, does not take up space, and has one more layer of explosion-proof measures.

[0038] In this example, the closed-cell polyurethane material is prepared from isocyanate, combined polyether and metal powder; among them, the isocyanate is dimethylmethane diisocyanate isomer, and the combined polyether has a density of 200kg / m 3 , the closed cell rate is 95%, and the polyurethane material with a pore size of 0.1mm is compressed with a compressive strength of 600kPa. The metal powder is copper powder with a particle size of 60 microns. The weight...

Embodiment 3

[0040] On the basis of Example 1, the shell bladder made of steel plate in step (1) is replaced by shell shell 5 made of composite material, and several ribs 6 are added on the inner surface of shell shell 5 to strengthen the shell The rigidity of the tube 5 is to better achieve the purpose of vacuuming, reduce the impact strength of the explosion itself, and reduce the strong noise of the explosion, so as to ensure that the side of the tube of the shell tube 5 will not leak high-speed debris outward, ensuring flight safety .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com