Detecting method for elastic modulus and strength of fragile coating layer

A technology of elastic modulus and test method, which is applied in the direction of strength characteristics, the use of stable tension/pressure to test the strength of materials, and measurement devices, which can solve the problems of insufficient evaluation technology of film mechanical properties, unstable data, and rare reports. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

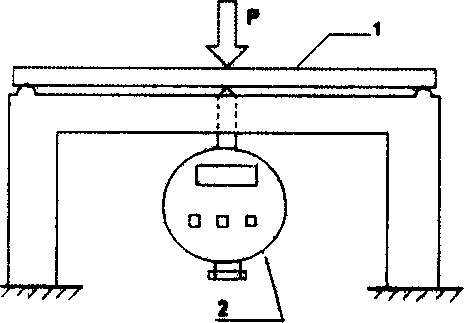

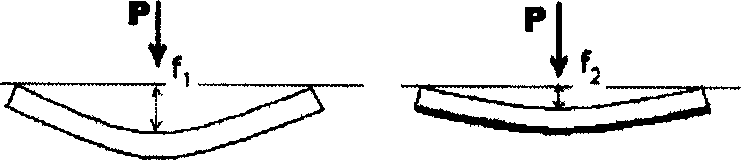

[0041] Such as Picture 1-1 , 1-2 , diagram 2-1 , Pic 4-1 , 5-1 As shown, taking the elastic modulus and strength of the four-sided silicon carbide coating formed on the surface of the graphite substrate by CVD as an example, the length of the beam sample is 40 mm, the width B of the beam sample before coating is 4 mm, and the thickness of the beam sample before coating is H is 3mm, the film thickness h is about 0.18mm, the span L is 30mm, and the elastic modulus of the graphite matrix is about 10GPa. The displacement is tested with a precision dial gauge. The measured elastic modulus of the silicon carbide coating is about 324GPa, and the strength is 249MPa. The results are basically consistent with the data measured with the single material.

[0042] Test method for elastic modulus of brittle film layer:

[0043] By comparing the changes in the bending stiffness of the beam sample under bending load before and after coating, according to the deformation of the beam ...

Embodiment 2

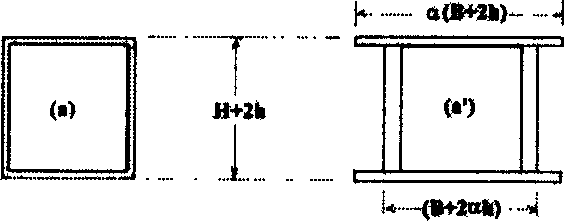

[0060] The difference with embodiment 1 is: as Figure 2-2 , image 3 , 4-2 , 5-2, taking the elastic modulus and strength of the single-sided glass film layer of the aluminum beam sample as an example, the length of the beam sample is 45mm, the span is 40mm, and the width B of the beam sample before coating is 4mm , the thickness H of the coated front beam sample is 3 mm, the load increment is 4 kg, and the displacement is tested by a precision dial gauge. The elastic modulus of the boron glass film layer on the surface of the aluminum alloy is measured to be about 68GPa, and the strength is about 120MPa. The results are basically consistent with the data measured with single material.

[0061] The expression of the moment of inertia of the asymmetric beam specimen coated on the lower surface is:

[0062] I b = BH 3 12 + α...

Embodiment 3

[0069] The difference from Example 2 is that the elastic modulus of the hard plastic beam sample with the upper and lower aluminum thin layers is tested, and the moment of inertia expression of the beam sample with coating on both sides is:

[0070] I 2 = αBh 3 6 + αBh 2 ( h + H ) 2 + BH 3 12 ; - - ( 6 )

[0071] The expression (7) for the modulus ratio is derived from this:

[0072] α = E 2 E 1 = I 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com