Highly soluble, high molecular weight soy bean protein

A high-molecular-weight, high-solubility technology, applied in the protein composition of vegetable seeds, plant protein processing, protein food ingredients, etc., can solve the problems of high cost of isolates, complex process of isolates, and affecting uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

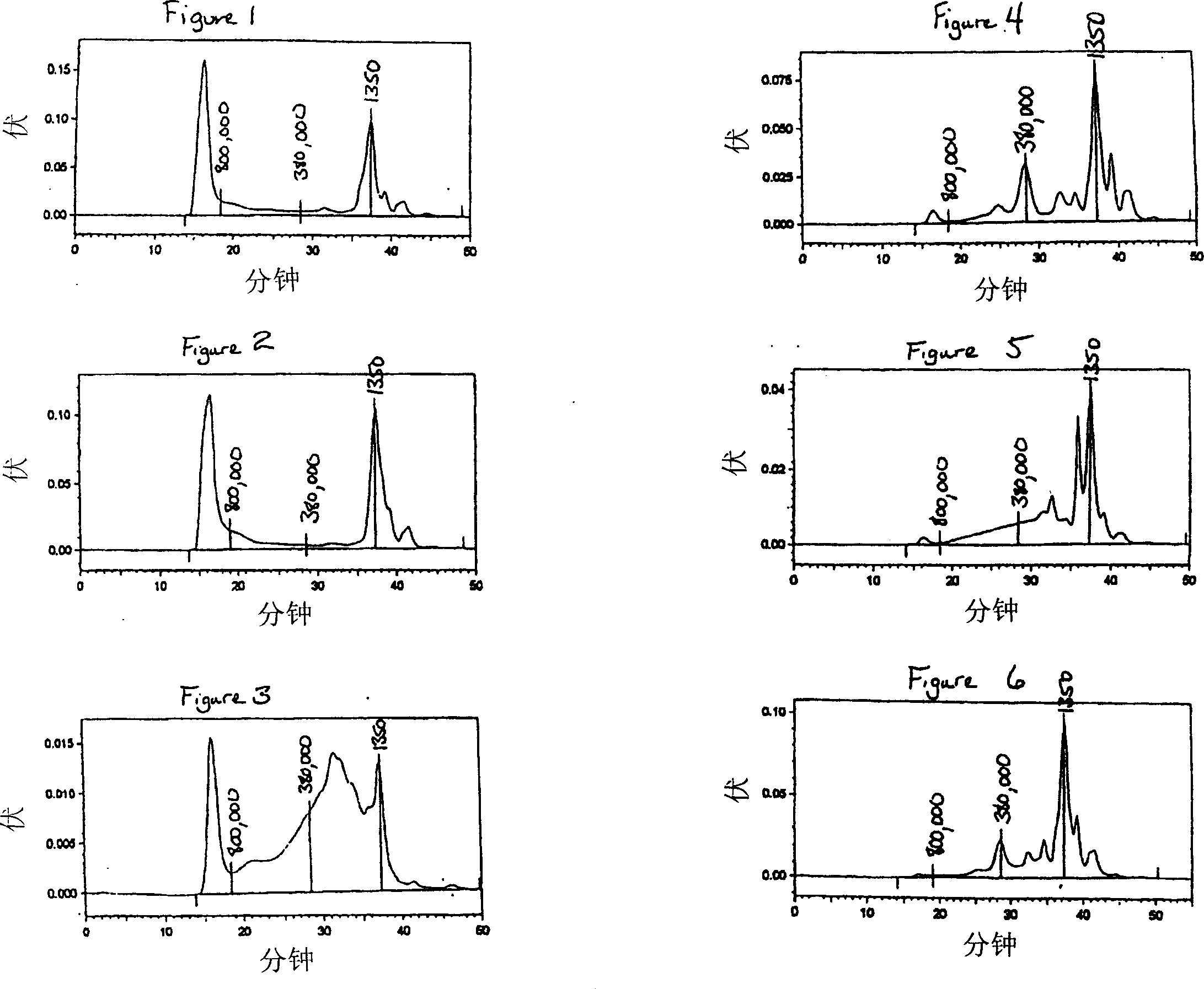

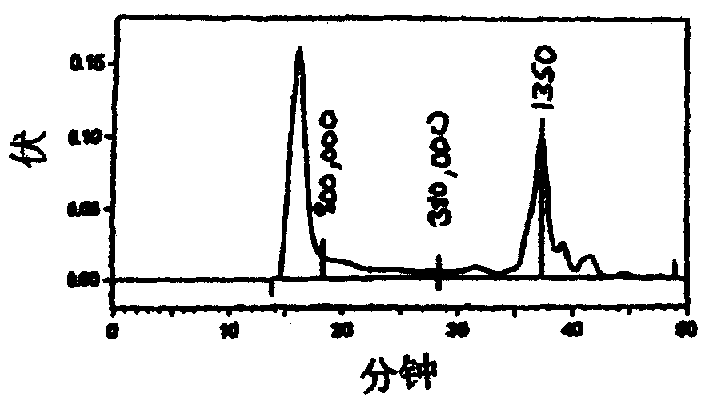

Image

Examples

preparation example Construction

[0043] The method for preparing protein product of the present invention comprises the following steps:

[0044] (a) providing soybean material defatted with hexane;

[0045] (b) adjusting the pH of the material;

[0046] (c) heating the material at an effective temperature for an effective time;

[0047] (d) removing fibers from the material;

[0048] (e) heat-treated materials;

[0049] (f) Dried material.

[0050] The product can be used in liquid or dry beverages, food or nutritional products.

[0051] The method of the present invention generally also comprises the following steps:

[0052] (1) soybean hulling;

[0053] (2) Roll the shelled soybeans into cakes;

[0054] (3) soybean oil is extracted from soybean cake with hexane solvent;

[0055] (4) removing the solvent of the defatted bean cake without heating or toasting to prepare a "white" cake;

[0056] (5) rolling bean cakes to prepare bean flour;

[0057] (6) Removal of fiber from soy flour and its protein....

Embodiment 1

[0086] At 32.2°C, disperse 22.7kg of soybean flour with a PDI of 86 into 235.4kg of water, and adjust the pH to 7.5 with NaOH. The suspension was stirred at 32.2 °C for 30 min and then centrifuged at 6000 rpm in a decanter centrifuge with a differential screw speed of 6. The insoluble centrifuge cake was discarded, and the supernatant was heat treated with a steam heater at 115°C for 15 seconds, then cooled to 140°F in a jacketed tank, and the pH was adjusted to 7.4 with HCl. The suspension was then spray dried. The spray dried product contained 59.0% protein, 1.5% crude fiber, 0.2% fat, 8.0% ash, 3% water.

[0087] The molecular weight of product is determined by above-mentioned method and standard, and the result is as shown in Figure 1. About 75% of the protein in the product has a molecular weight greater than 800,000.

Embodiment 2

[0089] At 60°C, disperse 22.7kg of soybean flour with a PDI of 86 into 235.4kg of water, and adjust the pH to 7.5 with NaOH. The suspension was stirred at 60°C for 30 minutes and then centrifuged in a decanter centrifuge. The insoluble centrifuge cake was discarded, and the supernatant was heat-treated with a steam heater at 121° C. for 15 seconds. The supernatant was then cooled to 48.9°C in a jacketed tank, and the pH was adjusted to 7.0 with HCl. The suspension was then subjected to ultrafiltration using a spiral wound membrane with a molecular weight cut-off (MWCO) of 10,000, removing approximately 75% of the feed volume of permeate. The retentate was heat treated with a steam heater at 93.3°C for 15 seconds. The retentate was then cooled to 60°C in a jacketed tank and spray dried.

[0090] The retentate has the following composition:

[0091] Protein (dry weight) (%) 79.79

[0092] Moisture (%) 1.23

[0093] Ash (as it is) (%) 6.87

[0094] Natural fiber (as is) (%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com