Preparation of maleic di-ester cationoid polymerisable emulsifier

A technology of maleic anhydride diesters and polymerized emulsifiers, applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., can solve the problem of insufficient stable emulsion, high reactivity, and the number of polymerizable emulsifiers There are not many problems, and the effects of avoiding the reduction of emulsification effect, simple reaction operation and excellent emulsification performance are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

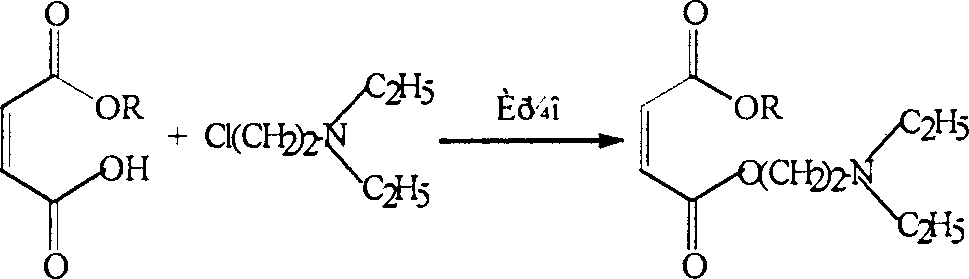

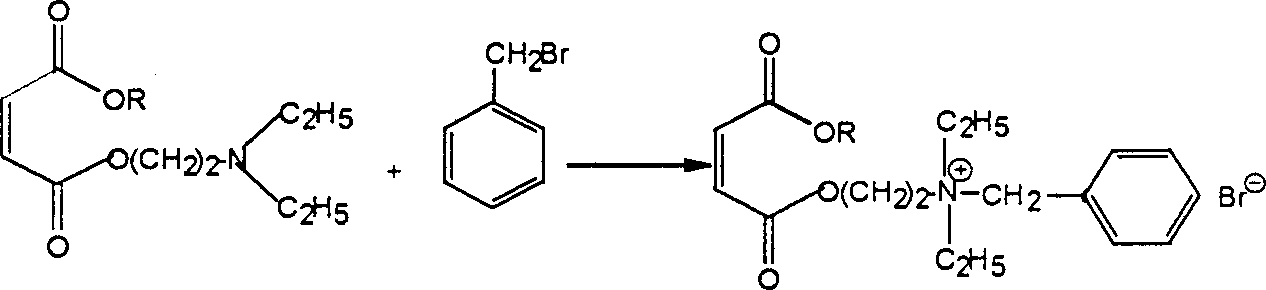

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of dodecyl maleic anhydride diester cationic polymerizable emulsifier

[0023] 1-1 prepare dodecyl maleic anhydride half ester by maleic anhydride and lauryl alcohol, reaction formula is as follows:

[0024]

[0025] Synthesis steps: Heat 49g (0.5mol) of maleic anhydride and 93g (0.5mol) of dodecanol to a molten state and react for 1h, then add 150ml of n-heptane, continue the reaction for 15min, then stir at room temperature for 3h, then at 15°C After reacting for 2-3 hours, the resulting white precipitate was collected and recrystallized with 150ml of n-heptane to obtain half ester of dodecyl alkyl maleic anhydride with a melting point of 58.9-59.3°C and a yield of 91.5%.

[0026] Infrared spectral analysis (IR, cm -1 , KBr): 3418 (OH), 1722 (C=O), 1646 (C=C).

[0027] NMR (600MHz, CDCl 3 )analyze:

[0028] δH: 0.89(t, 3H, CH 3 ), 1.27(m, 18H, (CH 2 ) 9 ), 1.73 (m, 2H, CH 2 ), 4.30(t, 2H, CH 2 O), 6.37-6.50 (d, 2H, HC=CH).

[0029] 1...

Embodiment 2

[0039] Example 2 Preparation of cetyl maleic anhydride diester cationic polymerizable emulsifier

[0040] 2-1 Prepare hexadecyl maleic anhydride half ester from maleic anhydride and cetyl alcohol, the reaction formula is as follows:

[0041]

[0042] Synthesis steps: Heat 49g (0.5mol) of maleic anhydride and 121g (0.5mol) of cetyl alcohol to a molten state for 1 hour, then add 150ml of n-heptane, continue the reaction for 15mm, then stir at room temperature for 3 hours, then at 15°C After reacting for more than 2 hours, the resulting white precipitate was collected and recrystallized with 150 ml of n-heptane to obtain hexadecyl maleic anhydride half ester with a melting point of 58.9-59.3°C and a yield of 92.3%.

[0043] Infrared spectral analysis (IR, cm -1 , KBr): 3415 (OH), 1722 (C=O), 1639 (C=C).

[0044] NMR (600MHz, CDCl 3 )analyze:

[0045] δH: 0.90(t, 3H, CH 3 ), 1.30(m, 26H, (CH 2 ) 13 ), 1.75 (m, 2H, CH 2 ), 4.31(t, 2H, CH 2 O), 6.38-6.52 (d, 2H, HC=CH). ...

Embodiment 3

[0056] Example 3 Preparation of octadecyl maleic anhydride diester cationic polymerizable emulsifier

[0057] 3-1 Prepare octadecyl maleic anhydride half ester from maleic anhydride and stearyl alcohol, the reaction formula is as follows:

[0058]

[0059] Synthetic steps: Heat 49g (0.5mol) maleic anhydride and 135g (0.5mol) octadecyl alcohol to molten state for 1h reaction, then add 150ml of n-heptane, continue the reaction for 15min, then stir at room temperature for 3h, then at 15°C The reaction was carried out for 2-3 hours, and the resulting white precipitate was collected and recrystallized with 150 ml of n-heptane to obtain octadecyl maleic anhydride half ester with a melting point of 58.9-59.3° C. and a yield of 91.8%.

[0060] Infrared spectral analysis (IR, cm -1 , KBr): 3417 (OH), 1722 (C=O), 1646 (C=C).

[0061] NMR (600MHz, CDCl 3 )analyze:

[0062] δH: 0.88(t, 3H, CH 3 ), 1.26(m, 30H, (CH 2 ) 15 ), 1.72 (m, 2H, CH 2 ), 4.30(t, 2H, CH 2 O), 6.38-6.51 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com