Hydrogenorator with water lubricated bearing structuve

A technology for water turbine generators, water lubricated bearings, applied in the direction of bearing components, shafts and bearings, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

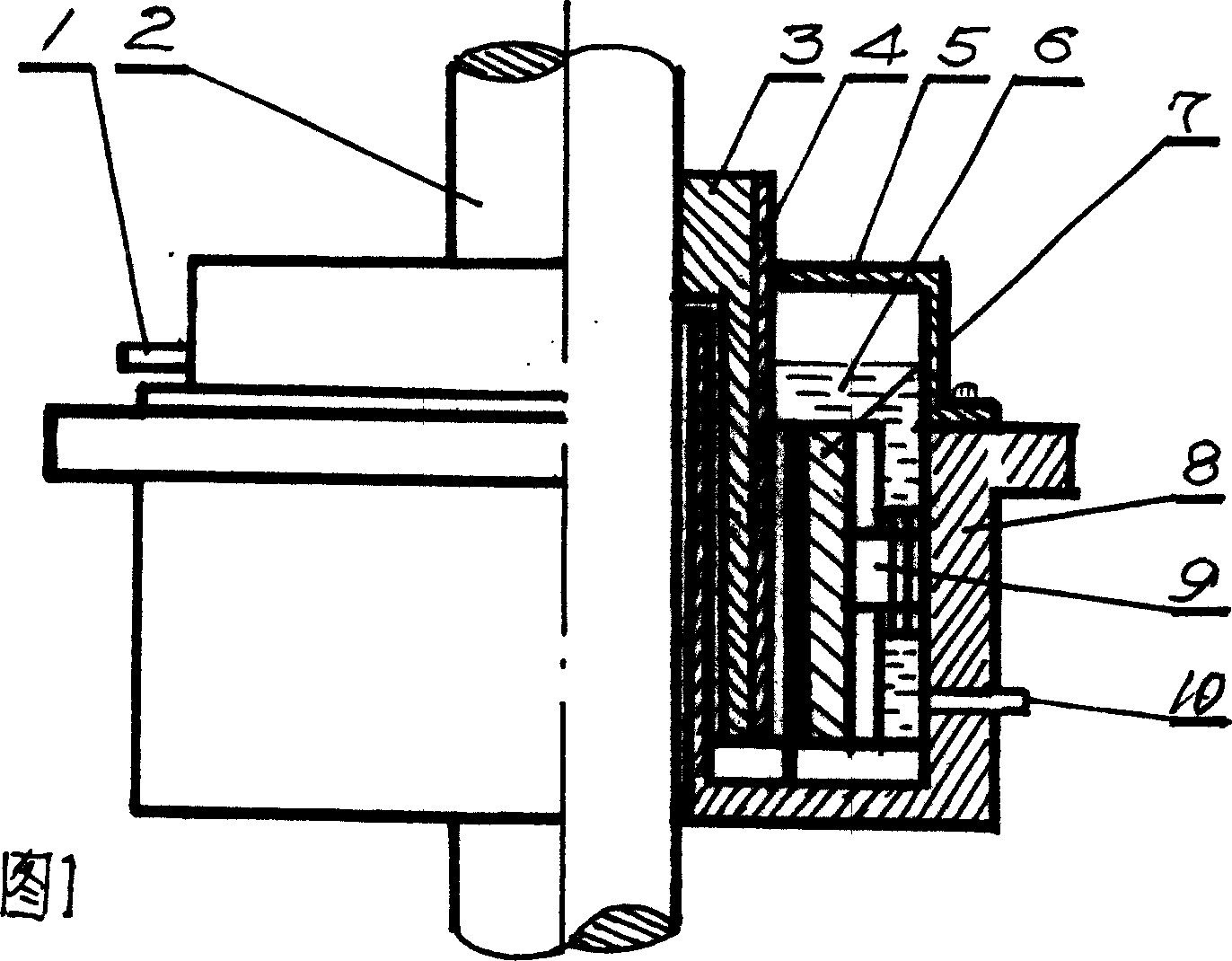

[0011] Example 1, the segmented water lubricated bearing of hydroelectric generator are described as follows in conjunction with accompanying drawing 1 and accompanying drawing 2. The journal 3 is fixed on the main shaft 2 of the water turbine, and its surface is compounded with a stainless steel layer 4, and the surface roughness of the journal 3 in frictional contact with the segmented guide bearing bush 7 is lower than 0.8 microns. The bearing bush is supported on the side wall of the water bearing basin 8 by means of support bolts 9 . Water inlet pipe 10 is installed in the basin bottom, and cold water 6 flows into the basin and fills up therefrom and draws water pipe 1 to flow out on cover 5. Block guide bearing bush 7 is by the tile base of steel, and its surface is brazed with the thick stainless steel wire layer of 5.0mm, and stainless steel wire city is inlaid into 0.5~1.5mm in the plastic tile surface, and plastic layer is thick 2.0~3.0mm. The semi-tightness of the ...

example 2

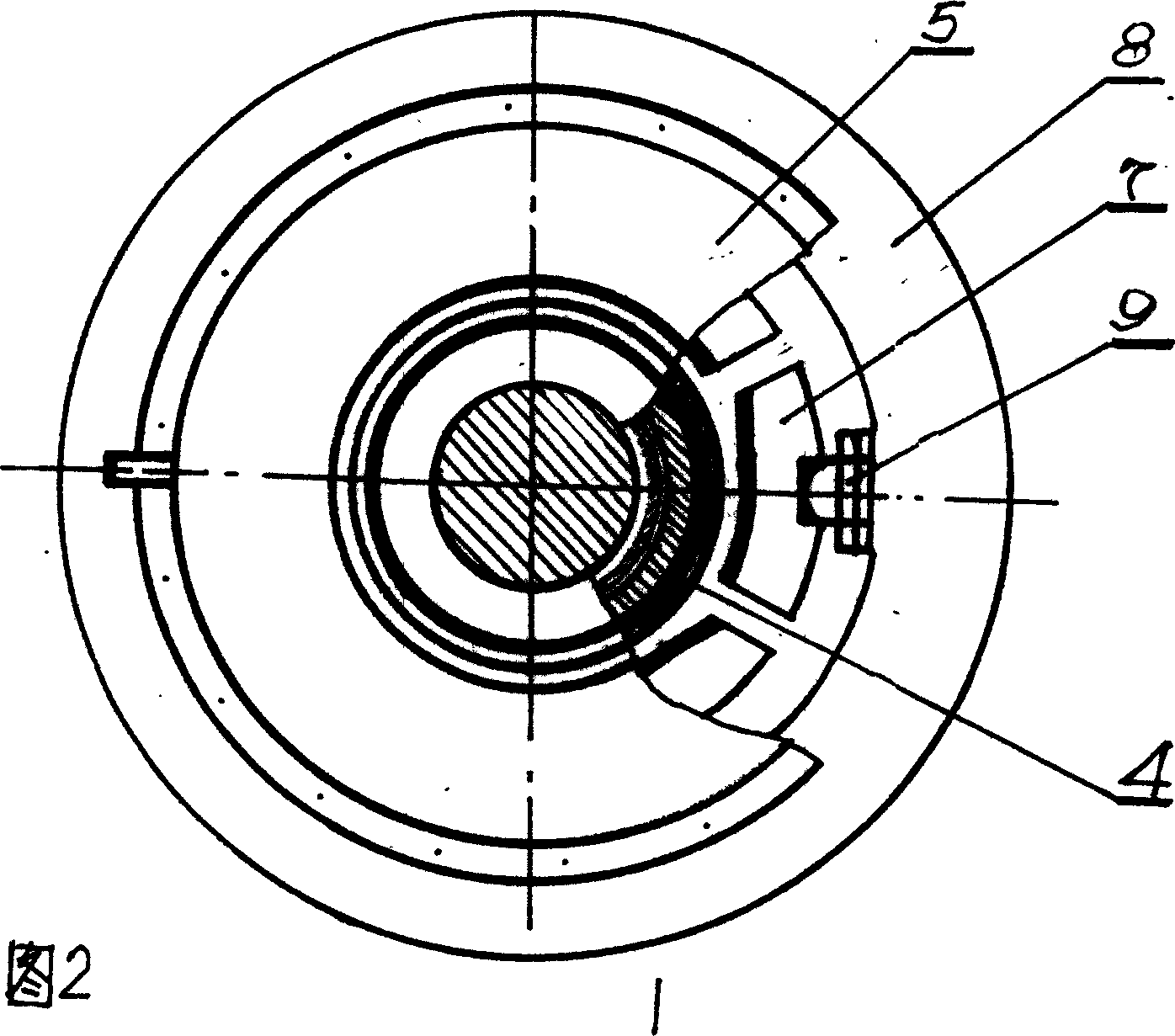

[0012] Example 2. The bearing shell of the cylindrical water-lubricated bearing of the hydroelectric generator is shown in Figure 2. Due to the shell type cylinder type, the pad base 11 is a steel structure. Its inner surface is brazed with tube alloy wire layer 12, and the thickness of the modified layer is 4.0-5.0 mm, and the plastic tile surface 13 and copper alloy wire layer 12 are inlaid with 0.5-1.5 mm. Plastic tile surface 13 is divided into 4 sections by the gutter 14 that is inclined along the direction of rotation, and every section is provided with water inlet wedge surface 17, and its length is 1 / 4 of the circumferential length of this section plastic surface. The water outlet wedge surface 15 is 1 / 9 of the circumferential length of this section. The ratio of the bearing surface 16 to the bearing reaches 0.1 to 0.3mm.

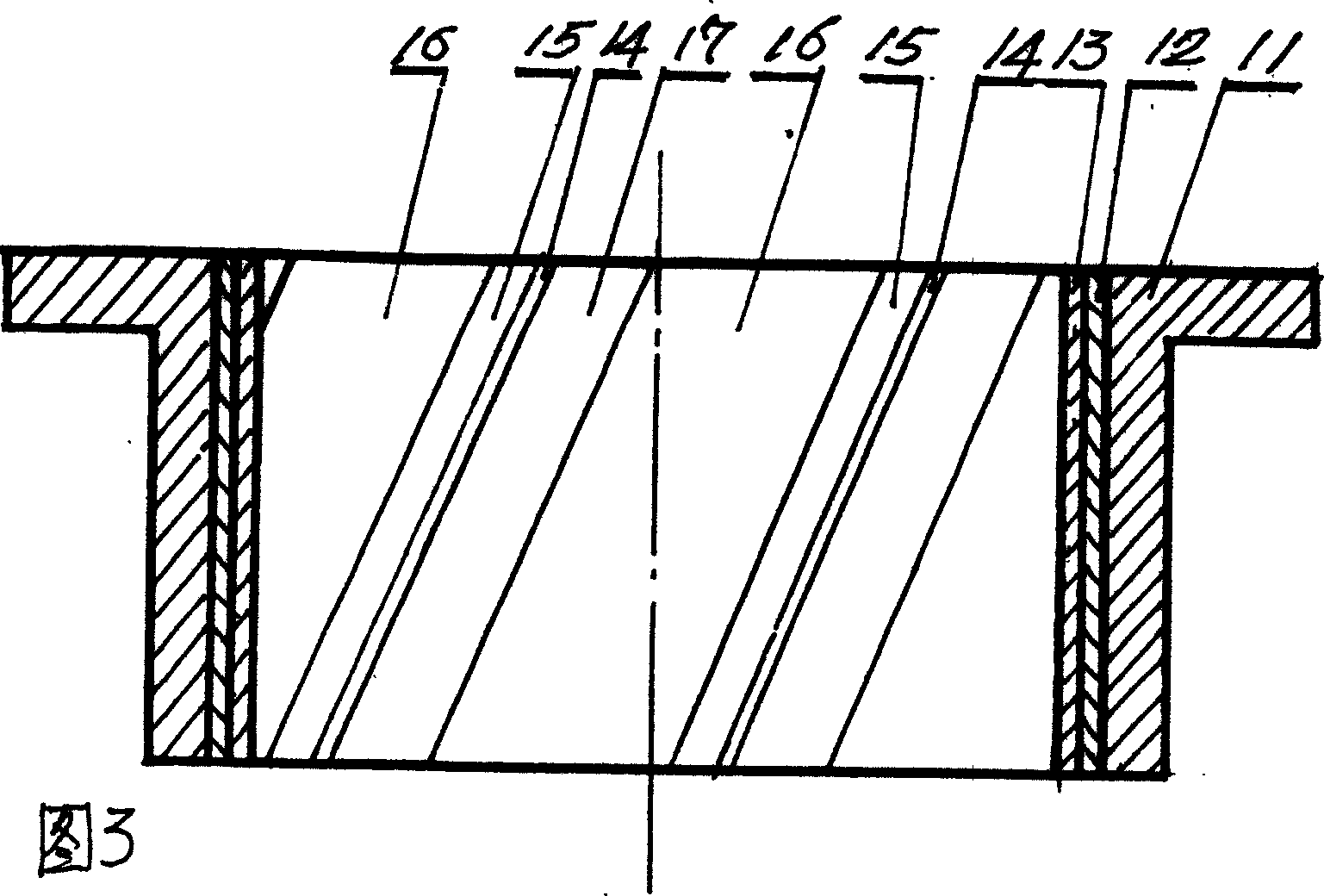

[0013] Example 3, the structure of the horizontal water-lubricated bearing is that the surface of the main shaft 25 is welded with a layer of sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com