Method and apparatus for recovering float oil on sea by magnetic fluid power

A power recovery and magnetic fluid technology, which is applied in separation methods, grease/oily substance/float removal devices, and open-air water surface cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

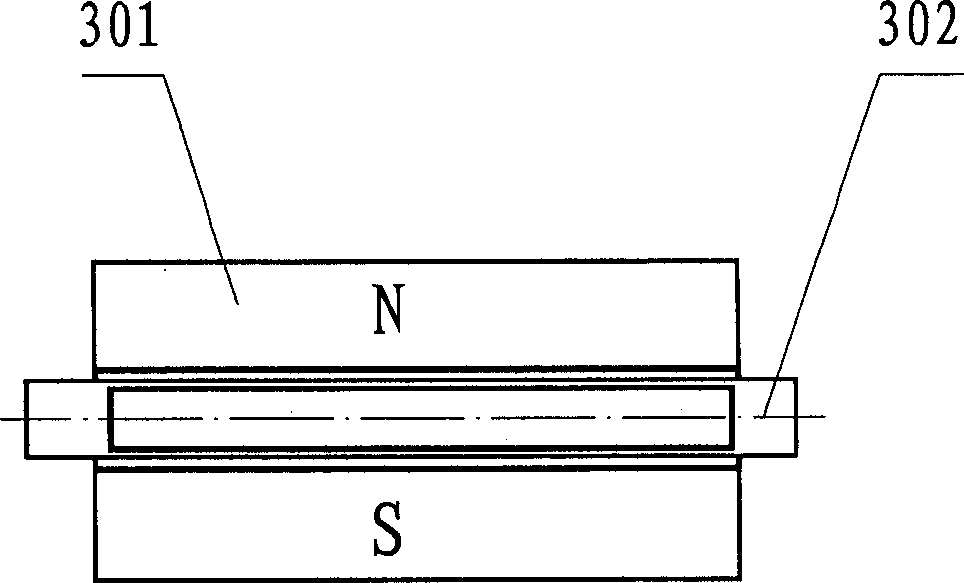

[0018] The method and device for recovering floating oil on the surface of the sea by magnetic fluid power utilizes the magnetic fluid power generated by the magnetic fluid propeller to pressurize and accelerate the oily seawater in the magnetic fluid channel, and then in the volute oil-water separation chamber (oil-water separation oil-repelling worm) The oil slick layer becomes thicker and is recovered through the oil discharge pipe, and the separated seawater is sprayed out from the tail nozzle.

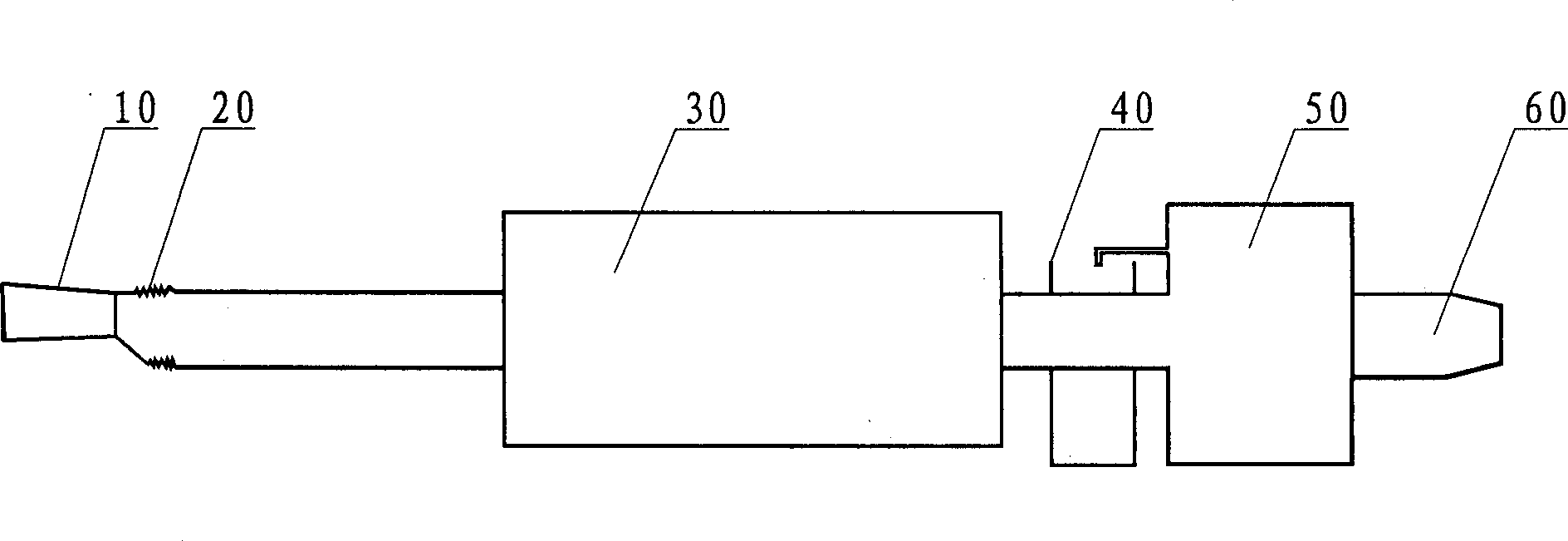

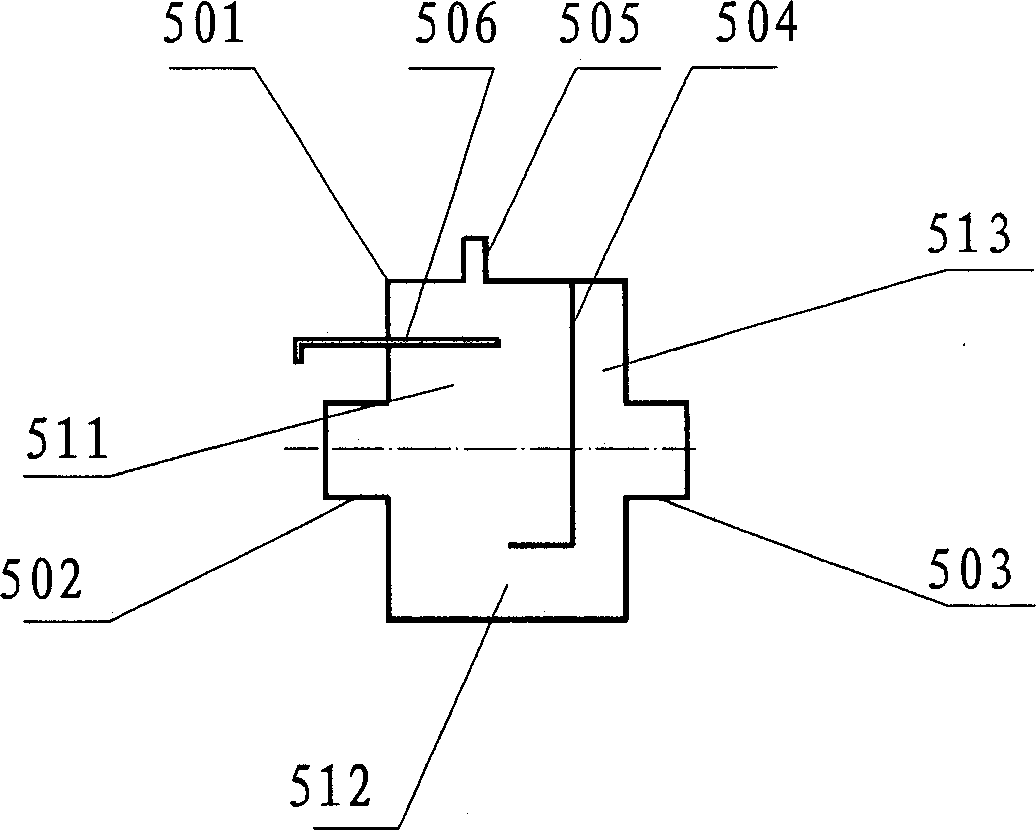

[0019] The device of magnetic fluid power recovery sea surface oil slick designed by the method of the present invention is as figure 1 As shown, it includes a floating flat trumpet-shaped water suction port 10 connected in sequence, a flexible transition guide section 20, the inlet section is higher than the outlet section, a magnetic fluid propeller 30, and a recovery oil tank 40, oil-water separation and oil resistance Worm 50 and tail nozzle 60. The detailed structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com