Micromoleculer capsule and its preparation method and application

A micro-molecule and capsule technology, applied in the field of micro-molecule capsules, can solve the problems of core material limitations, highly volatile fragrance substances, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

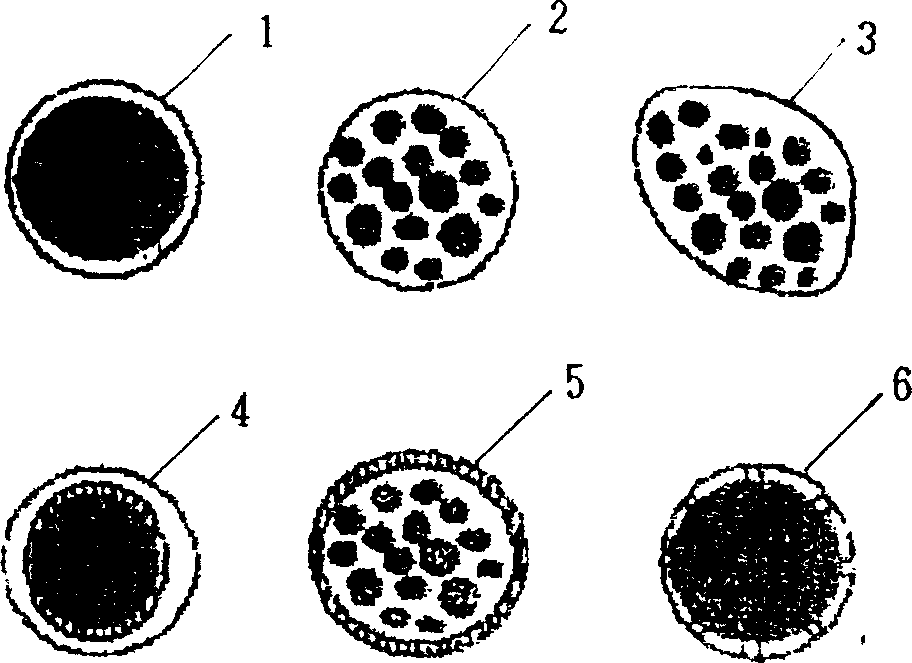

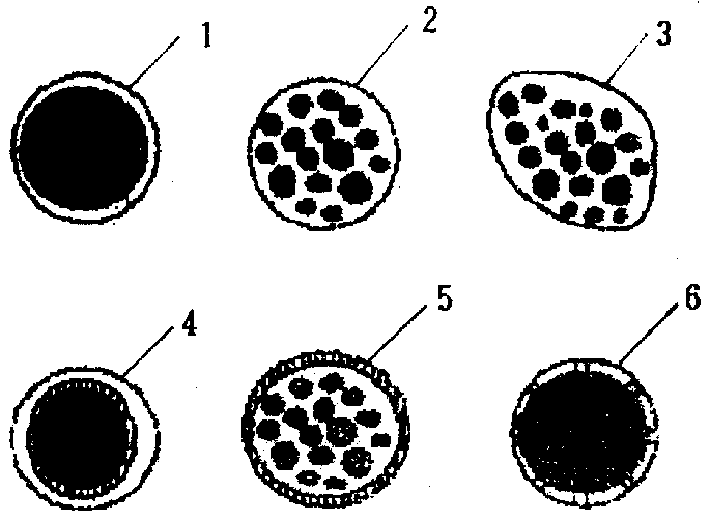

Image

Examples

Embodiment 1

[0043] Pour 0.5 parts by weight of calcium lactate into 100 parts by weight of water, pour in while stirring until a homogeneous phase is formed, then pour 60 parts by weight of polyamino acid and 13 parts by weight of cyclodextrin into it, and stir to form a homogeneous phase. Phase encapsulation slurry; control the temperature of the encapsulation slurry at 40° C. to 50° C., add 3 parts by weight of potassium malate to the encapsulation slurry as the capsule core material, and stir to make it homogenized. The mixed homogenate is sprayed, dehydrated and dried in a negative pressure hot air flow at 30°C to 55°C to form a solid powder with a particle diameter of ≤100 μm and a moisture content of ≤5%, which is the required micromolecular capsule.

Embodiment 2~9

[0045] Except that the capsule core material is potassium gluconate, zinc gluconate, manganese gluconate, zinc malate, manganese malate, potassium lactate, zinc lactate or manganese lactate, other processes are the same as in Example 1.

Embodiment 10

[0047] Repeat embodiment 1, following difference is arranged: the calcium lactate of 1 weight part is poured into the water of 100 weight parts, pours while stirring, until forming homogeneous phase, then the polyamino acid of 60 weight parts and 15 weight parts The cyclodextrin is poured into it and stirred into a homogeneous encapsulation slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com