Continuous preparing method for petroleum sulfosalt

A technology of petroleum sulfonate and sulfonating agent, which is applied in the direction of organic chemistry, etc., can solve the problems of difficult flow, uneven reactor wall, difficult membrane type continuous sulfonation method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

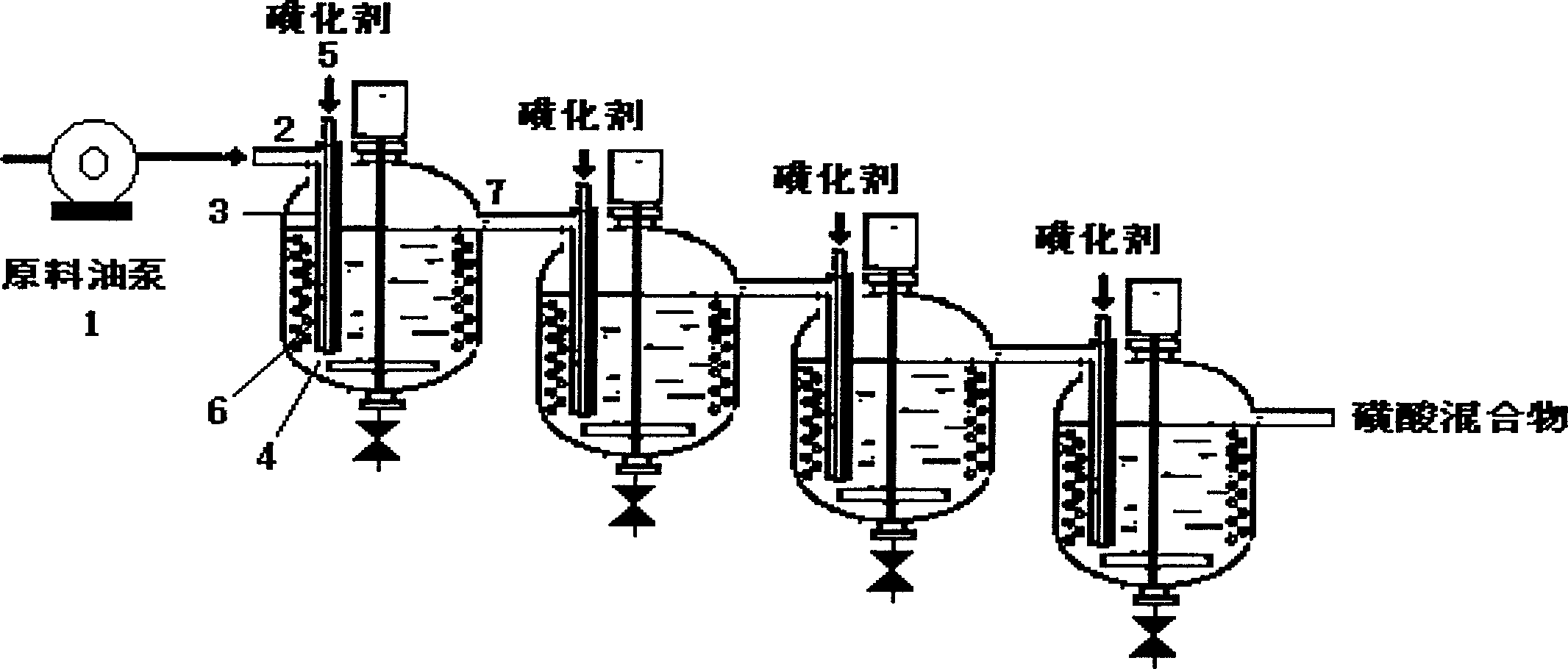

example 1

[0019] The raw material oil is straight run oil of Gudao crude oil, the sum of aromatics and colloid content (measured by column separation method) is 41.2%, and the freezing point and boiling point range are shown in Table 1. A 2:1 mixture (weight ratio) of raw oil and dichloroethane is injected into the first sulfonation reactor with a flow rate of 1800 g / hr by a metering pump. The sulfonating agent is a 25% sulfur trioxide solution diluted with dichloroethane, which is sent into the first to the fourth sulfonation reactors with a ratio of 40:25:25:10 with a metering pump, and the total flow is 1296g / h (sulfur trioxide: raw oil=0.27, weight ratio). The temperature of the first to fourth sulfonation reactors is controlled at -5°C, +5°C, +5°C and +15°C respectively, and the total residence time of materials in the four sulfonation reactors is 2hr. After the material flowing out of the device is neutralized with ammonia water to pH = 7, it is distilled at 130°C, the water is ...

Embodiment 2

[0022] The raw material oil is the aromatic fraction extracted from Liaohe crude oil. The sum of aromatic hydrocarbon and colloid content (measured by column separation method) is 75.7%. The freezing point and boiling point range are shown in Table 1. The mixture of raw oil and dichloroethane (2:1, weight ratio) is injected into the first sulfonation reactor with a metering pump, and the flow rate is 1800g / hr. The sulfonating agent is a 25% sulfur trioxide solution diluted with dichloroethane, which is sent into the first to the fourth sulfonation reactors with a ratio of 40:25:25:10 with a metering pump, and the total flow is 1728g / hr (sulfur trioxide: raw oil = 0.36, weight ratio). The temperatures of the first to fourth sulfonation reactors are all controlled at +5°C. All the other steps obtain the sulfonate product by example 1, and test the oil-water interfacial tension by the steps described in example 1 with the XZD-3 type interfacial tensiometer. The results are sho...

Embodiment 3

[0024] The feedstock oil is the aromatic fraction extracted from the normal third-line fraction of Iranian crude oil. The sum of aromatic hydrocarbon and colloid content (measured by column separation method) is 69.1%. The freezing point and boiling point range are shown in Table 1. The mixture of raw oil and dichloroethane (2:1, weight ratio) is injected into the first sulfonation reactor with a metering pump, and the flow rate is 1800g / hr. The sulfonating agent is a 25% sulfur trioxide solution diluted with dichloroethane, which is sent into the first to the fourth sulfonation reactors with a ratio of 50:20:20:10 with a metering pump, and the total flow rate is 1440g / hr (sulfur trioxide: raw oil = 0.30, weight ratio). All the other steps obtain the sulfonate product by example 1, and test the oil-water interfacial tension by the steps described in example 1 with the XZD-3 type interfacial tensiometer. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com