Foreign matter removnig device and method

A technology for foreign objects and blowing devices, applied in the field of scale skin devices, can solve the problems of pressure feeding rate limitation, long time, and increase in the appearance of abrasive equipment, and achieve constant flow rate, decompression/expansion compensation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

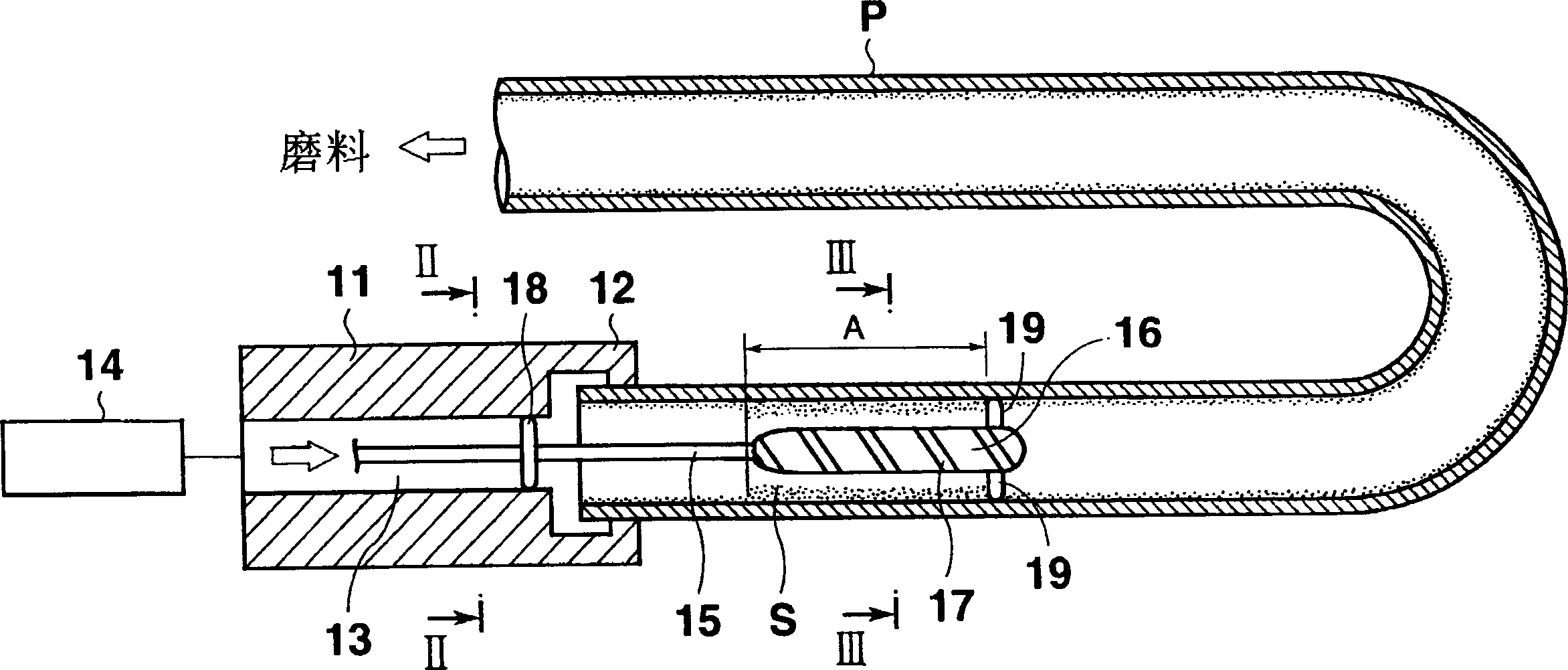

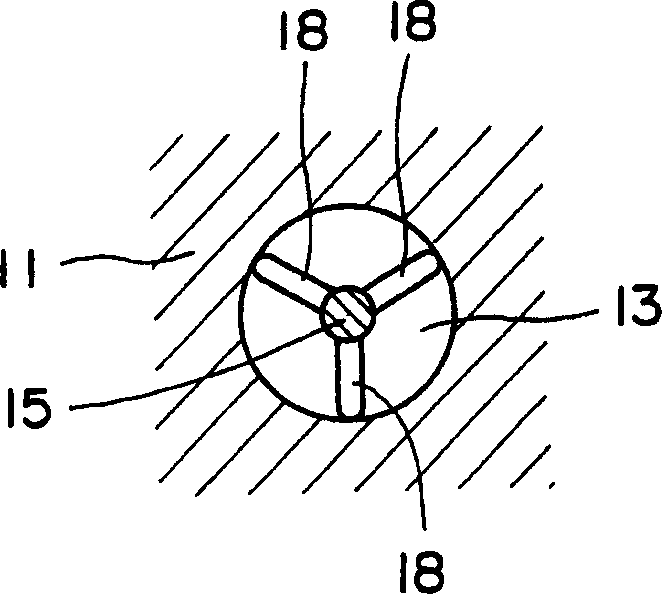

[0052] figure 1 is a schematic diagram of a foreign object removing device according to a first embodiment of the present invention. figure 2 means along figure 1 A cross-section taken on the plane II-II, image 3 means along figure 1 A cross-section taken on plane III-III.

[0053] Such as Figures 1 to 3 As shown, the foreign matter removing apparatus of the first embodiment is used, for example, to abrade scale S as foreign matter generated in a pipe P used as a heat transfer tube of a heat exchanger of a nuclear power plant or the like. In particular, a large amount of scale S is generated in the area A near the opening of the pipe P. As shown in FIG.

[0054] For example, when, for example, the tube sheet is made of SUS304, and the heat transfer tube is made of copper-nickel alloy, a large thickness layer having a thickness of 70 to 100 micrometers is produced in the region where the tube sheet and the outlet portion of the heat transfer tube are interconnected , r...

no. 2 example

[0070] Figure 5 A foreign object removing device according to a second embodiment of the present invention is schematically illustrated. In the first embodiment described above, the abrasive aid 16 is inserted from one end and the abrasive is sent from the same end using pressure. However, in the second embodiment, as Figure 5 Insertion and transmission are performed from opposite ends as shown.

[0071] and figure 1 Similar to the shown apparatus, the foreign matter removing apparatus of the second embodiment is used to abrade scale S generated as foreign matter in a pipe P used as a heat transfer tube of a heat exchanger or the like.

[0072] In particular, if Figure 5 As shown, in the foreign object removing device of this second embodiment, similar to figure 1 , the retainer 11 is freely connectable / detachable to one open end of the pipe P, and the retainer 11 has a blowing path 13 and an engaging portion 12 whose interior is circular in cross-section. Also, anoth...

no. 3 example

[0078] Figure 6 A device for removing foreign objects according to a third embodiment of the present invention is schematically shown. and figure 1 Similarly, the foreign matter removing device of this third embodiment is also used to abrade scale S generated as foreign matter in the pipe P used as a heat transfer tube of a heat exchanger or the like.

[0079] In this third embodiment, if Figure 6 As shown, the abrasive is sent from the blast device 14a into the pipe P by pressure. In addition to this, abrasive material is also sent by means of pressure from a further blower device 14 into the interior of the abrasive aid 16 in a direction opposite to the flow direction of the abrasive material in the pipe P. Thus, the abrasive is ejected from the inside toward the periphery of the abrasive assisting part 16 .

[0080] In this foreign matter removing device, as a holding mechanism for holding the abrasive assisting member 16, the figure 1 Similarly, a holder 11, a suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com