Crank shaft of refrigeration compressor

A technology for refrigeration compressors and crankshafts, which is applied to mechanical equipment, machines/engines, and liquid variable displacement machinery, etc. It can solve problems such as reduced lubrication performance and cooling performance, unsmooth supply of refrigeration oil, and inability to supply refrigeration oil in time. Achieve high centrifugal force and prevent refrigeration oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

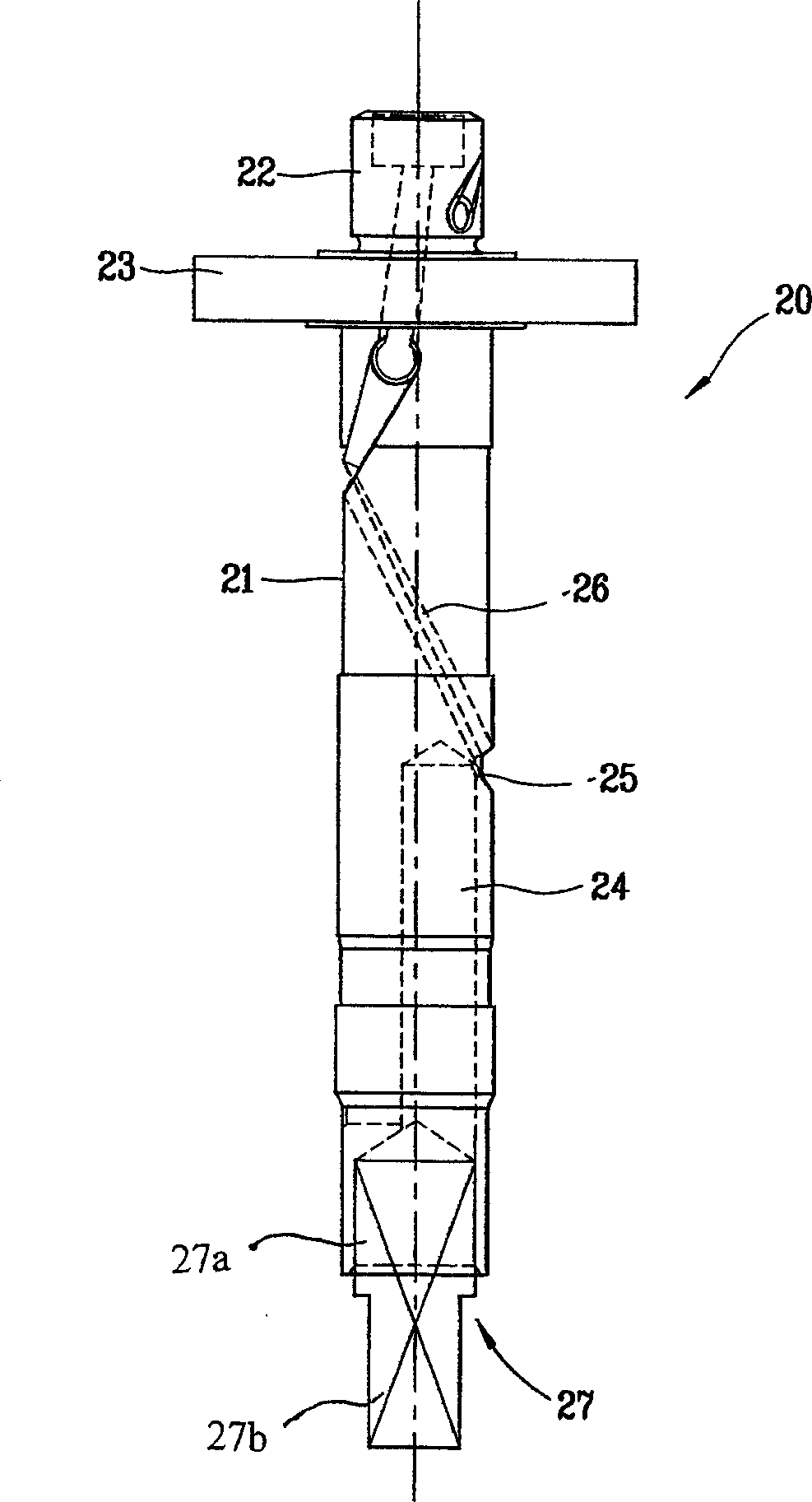

[0035] Such as Figure 4 The crankshaft shown is a form in which an oil pump is directly coupled to the lower end of the shaft. Such as Figure 4 As shown, the oil pump is composed of a hollow cylindrical plunger 37a inserted into the peripheral surface of the lower end of the shaft, and a thruster 37b obliquely provided inside the plunger to form a refrigerating machine oil ascending oil passage, and rotates on the shaft 31. A centrifugal oil pump that pumps out the refrigerating machine oil by the centrifugal force generated during the operation.

[0036]First, when power is supplied to the motor to rotate the rotor, the shaft portion 31 pressed into the rotor rotates accordingly. At this time, the refrigerating machine oil rises up by the propeller 37b of the oil pump by the centrifugal force and flows into the first oil groove 34 of the shaft. Next, the refrigerating machine oil rises through the oil passage between the first oil tank 34 and the rotor, and flows into th...

Embodiment 2

[0039] Figure 5 In the crankshaft shown, the oil pump is not directly connected to the shaft, but inserted into the lower end of the rotor.

[0040] Such as Figure 5 As shown, the plunger 47a of the above-mentioned oil pump is inserted into the lower end of the rotor 5 by a predetermined length, and the plunger 47a is separated from the lower end of the shaft portion 31 by a predetermined interval. At this time, there is no problem even if the plunger 47a is tangent to the shaft portion 31 . In this case, an O-ring should be provided between the plunger 47a and the rotor 5 in order to prevent oil leakage of the refrigerating machine.

[0041] When electricity is applied and the electric part rotates the rotor, the shaft part 31 rotates together with the oil pump. At this time, the refrigerating machine oil rises under the action of the propeller 47b of the oil pump by centrifugal force and flows into the first oil groove 34 of the shaft portion, and the subsequent functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com