Two-phase mixed conductor oxygen-breathable film

A hybrid conductor, oxygen-permeable membrane technology, applied in semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve the problems of high tension, material cracking and fragmentation, and high cost of dual-phase membrane preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

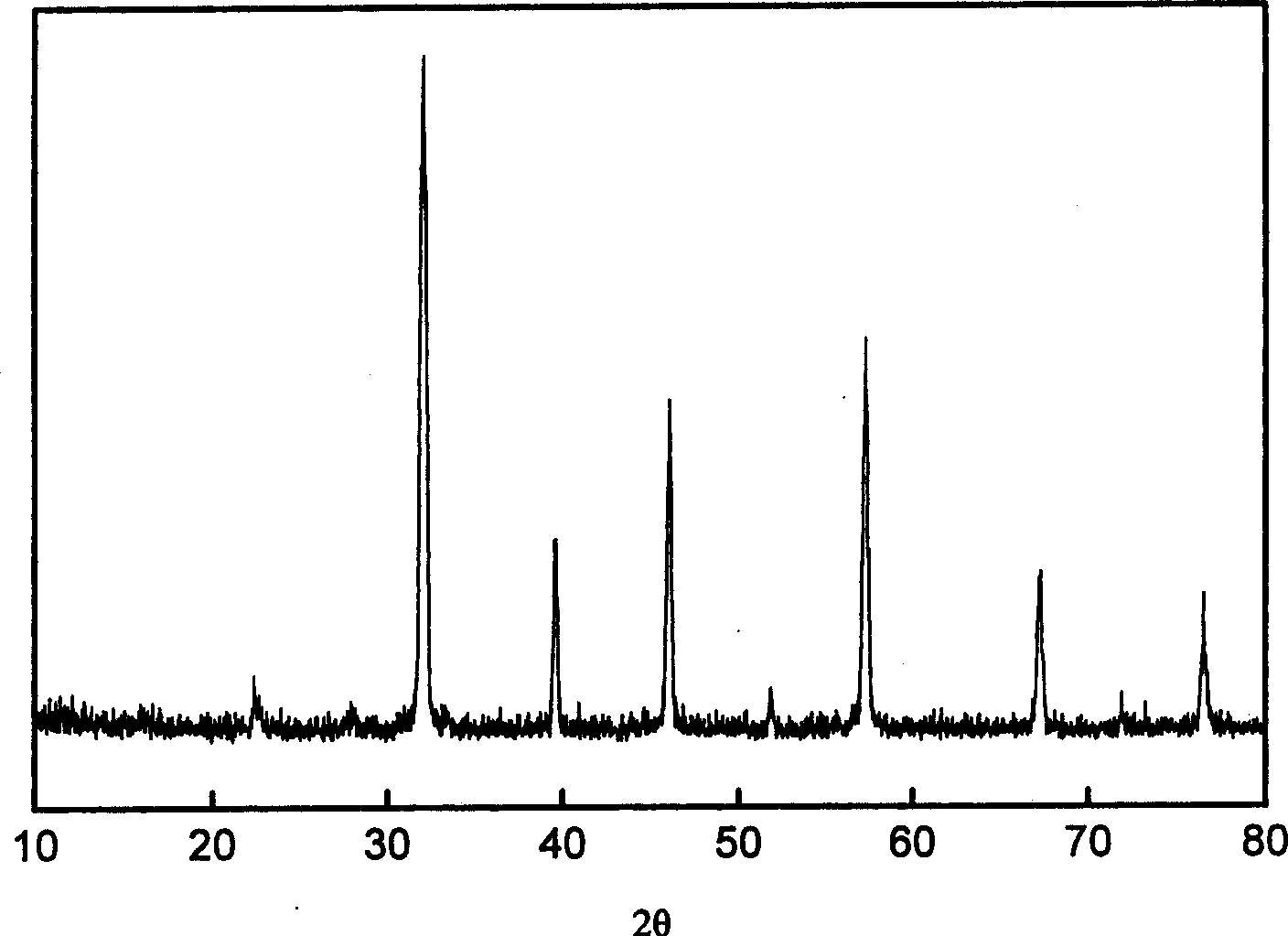

[0032] Synthesis of La by Citric Acid Complexation 0.15 Sr 0.85 Ga 0.3 Fe 0.7 o 3-δ .At first accurately weigh 2.092g metal gallium (99.999%), make it dissolve with nitric acid solution, pipette 19.36ml concentration and be 0.7747M La(NO 3 ) 3 , 91.80ml of Sr(NO 3 ) 2 , 42.11ml of Fe(NO 3 ) 3 , mix them to form a mixed solution, add 78.18g EDTA and 42.03g citric acid, and then use NH 3 .H 2 O adjusts the pH of the solution to 6.0, heats and stirs the solution at a constant temperature of 80°C, and finally obtains a purple-red colloid with the continuous evaporation of water, pretreats the colloid at 150°C and decomposes the initial powder at 950°C Calcined at ℃ for 5h to obtain LSGFO powder. It was detected as pure phase perovskite by XRD.

Embodiment 2

[0034] Synthesis of citric acid complexation.Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ .The Ba(NO 3 ) 2 , 54ml concentration is 0.9259MSr (NO 3 ) 2 Solution, 12.03ml concentration is 1.6622M Fe(NO 3 ) 3 Solution, 79.01ml concentration is 1.0125M Co(NO 3 ) 2 solution, mix them evenly, add 74.45g EDTA and 63.04g citric acid, use NH 3 Adjust the pH to 6.0, heat and stir the solution at a constant temperature of 80°C, and finally obtain a purple-red colloid with the continuous evaporation of water, pretreat the colloid at 150°C for preliminary decomposition, and put the primary powder at 950°C Calcined for 5h to obtain BSCFO powder. It was detected as pure phase perovskite by XRD.

Embodiment 3

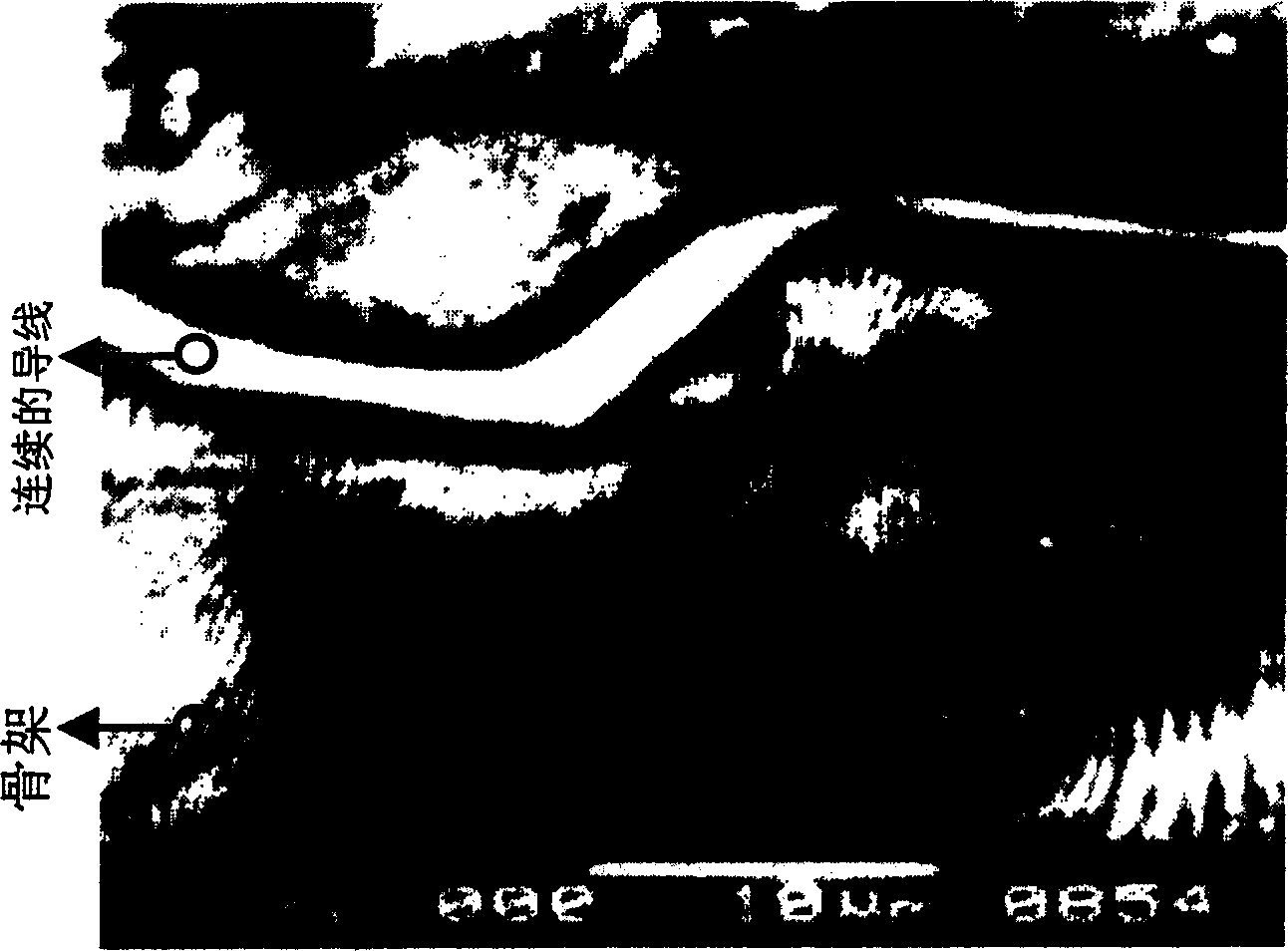

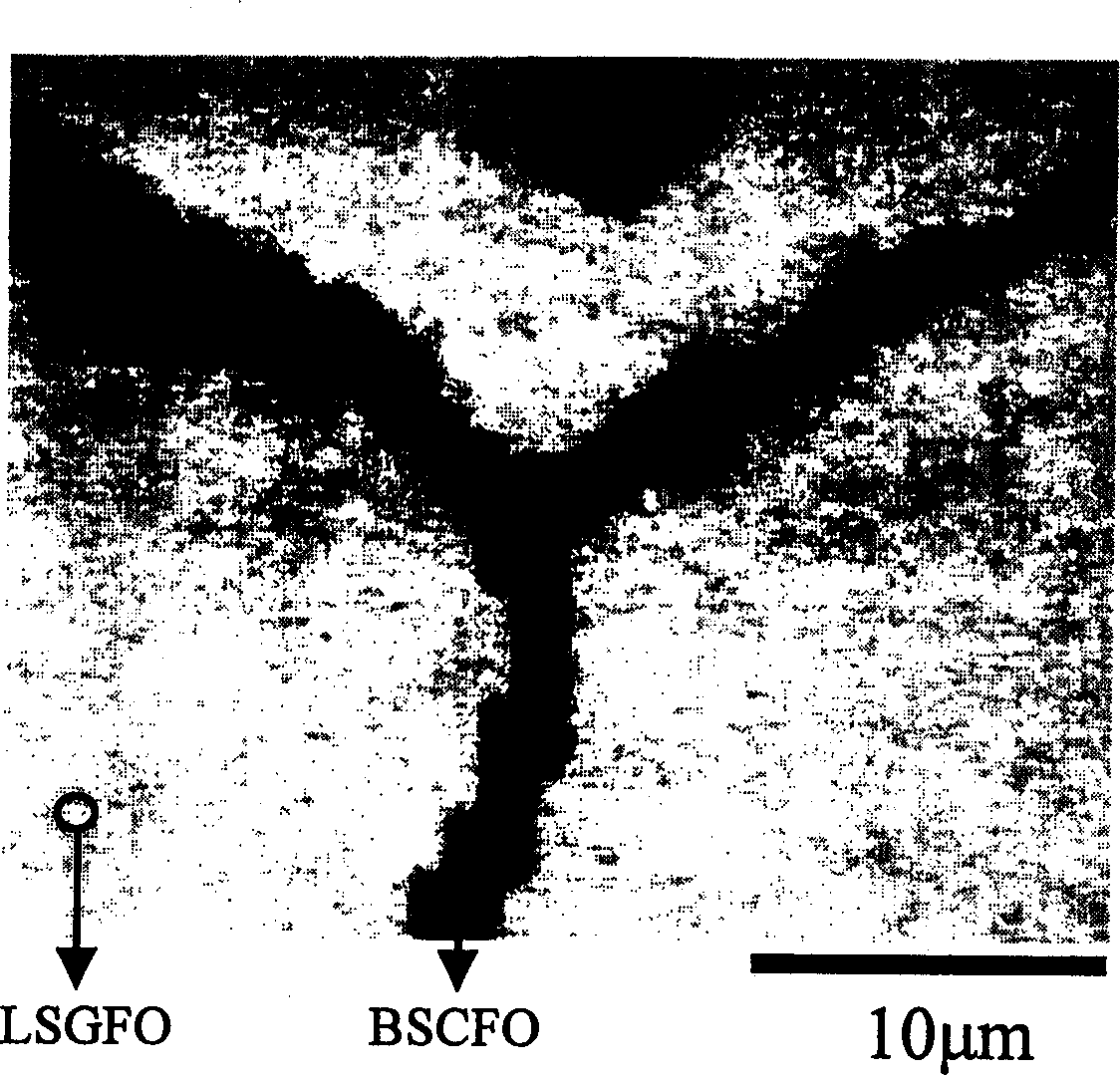

[0036] Preparation of dual-phase LSGFO-BSCFO sheet-like oxygen-permeable membrane: The synthesized LSGFO and BSCFO powders are ground and sieved to below 200 mesh. Then use a graduated cylinder to measure 12.8ml of LSGFO powder and 1ml of BSCFO powder, mix them evenly, and grind them with a ball mill for 20 hours. Then it is formed into pieces on a single-axis hydraulic press with a pressure of 15-20T / cm 2 . The dense LSGFO-BSCFO dual-phase membrane can be obtained by sintering the membrane at 1200°C for 10 hours. Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com