Method and device for connecting plastic material using high welding speed

A technology of plastic materials and transparent materials, which can be used in welding/welding/cutting items, welding equipment, laser welding equipment, etc., and can solve problems such as poor welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

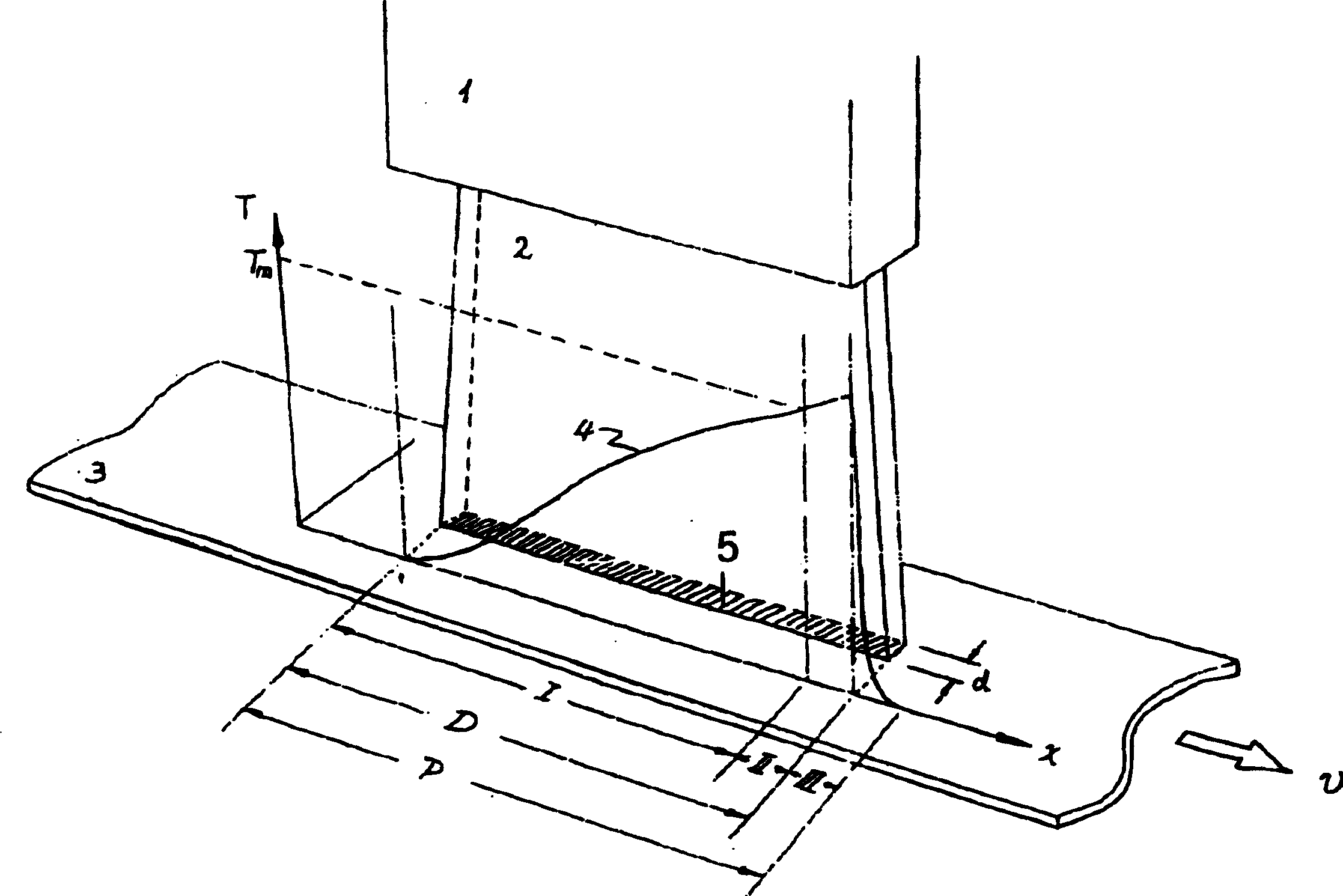

[0027] figure 1 Shown is a laser source 1 with a curtain-like collimated laser beam 2 which produces a linear irradiation field 5 on a plastic material 3 . The width d and length D of the irradiation field 5 can be influenced by a corresponding optical system. Plastic material 3 moves with velocity v in the direction of the arrow. Furthermore, the temperature curve 4 of the temperature T versus the distance x is shown in the figure. As shown in the figure and line 4, the temperature in the material continues to increase in the preheating zone I and finally reaches the melting temperature. From here melting zone II begins and ends in irradiation zone 5, the length of which is denoted by D. Thereafter the temperature starts to drop in cooling zone III. The overall duration of the welding process is denoted by P.

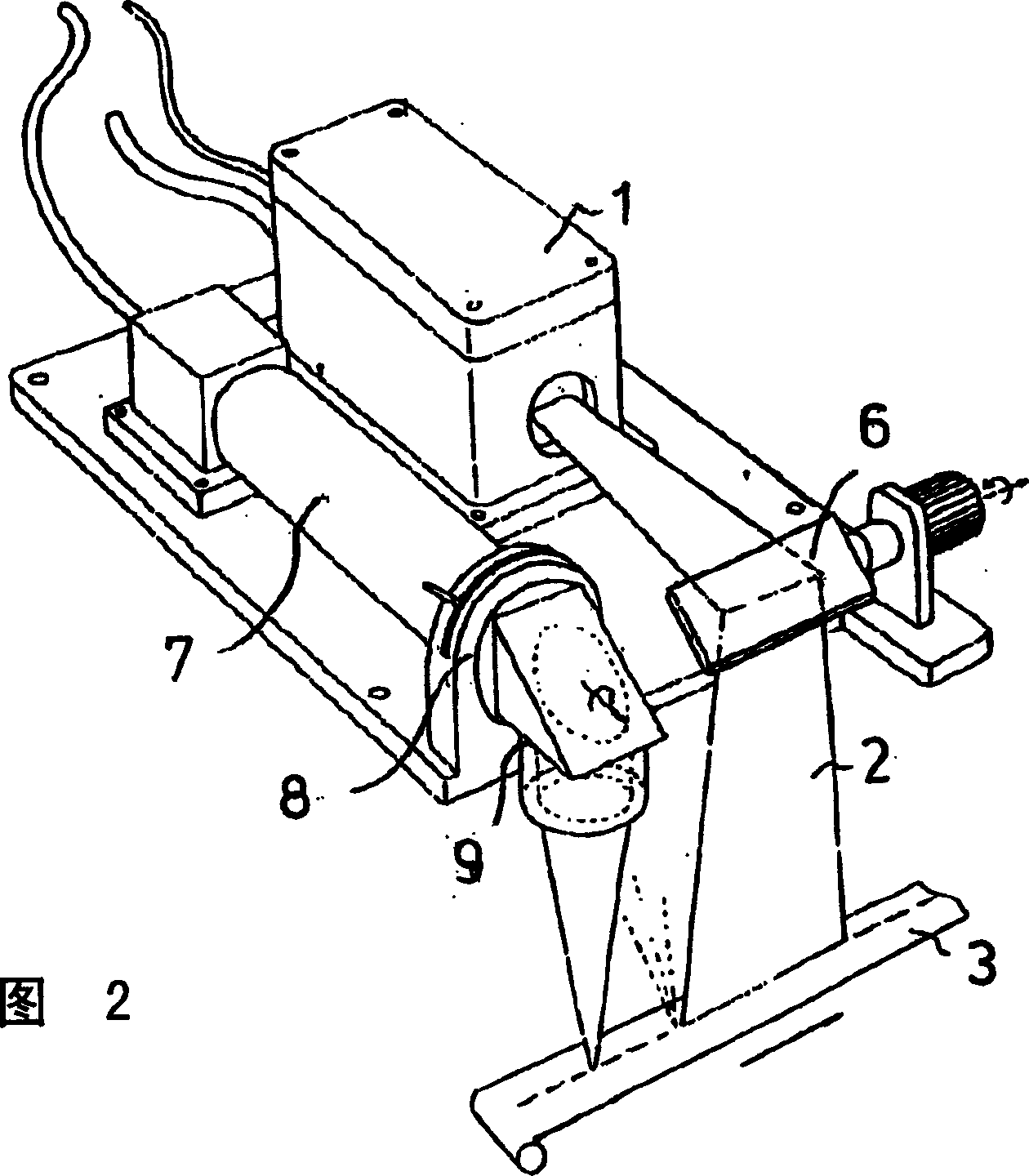

[0028] A structure is shown in Figure 2 to illustrate the principle, which shows figure 1 The curtain laser beam 2 of the laser beam is irradiated on a material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com