Copper casing pipe coiler

A technology of copper sleeve and coil machine, which is applied in the bending and forming processing of sleeve pipes and the preparation of copper sleeves, and can solve the problem of uneven stress on the inner and outer tubes of the sleeve and deformation of the inner and outer tubes Inhomogeneity, large volume and quality of copper casing, etc., to achieve good stable support and transmission effect, convenient adjustment and maintenance, and reduce the labor intensity of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

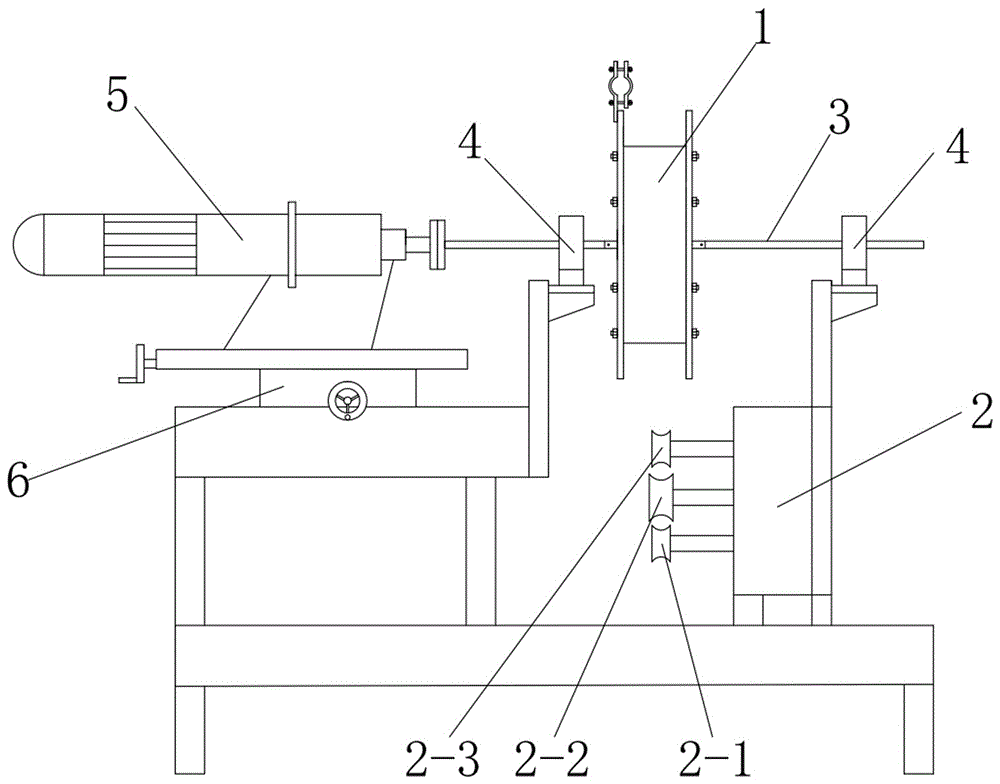

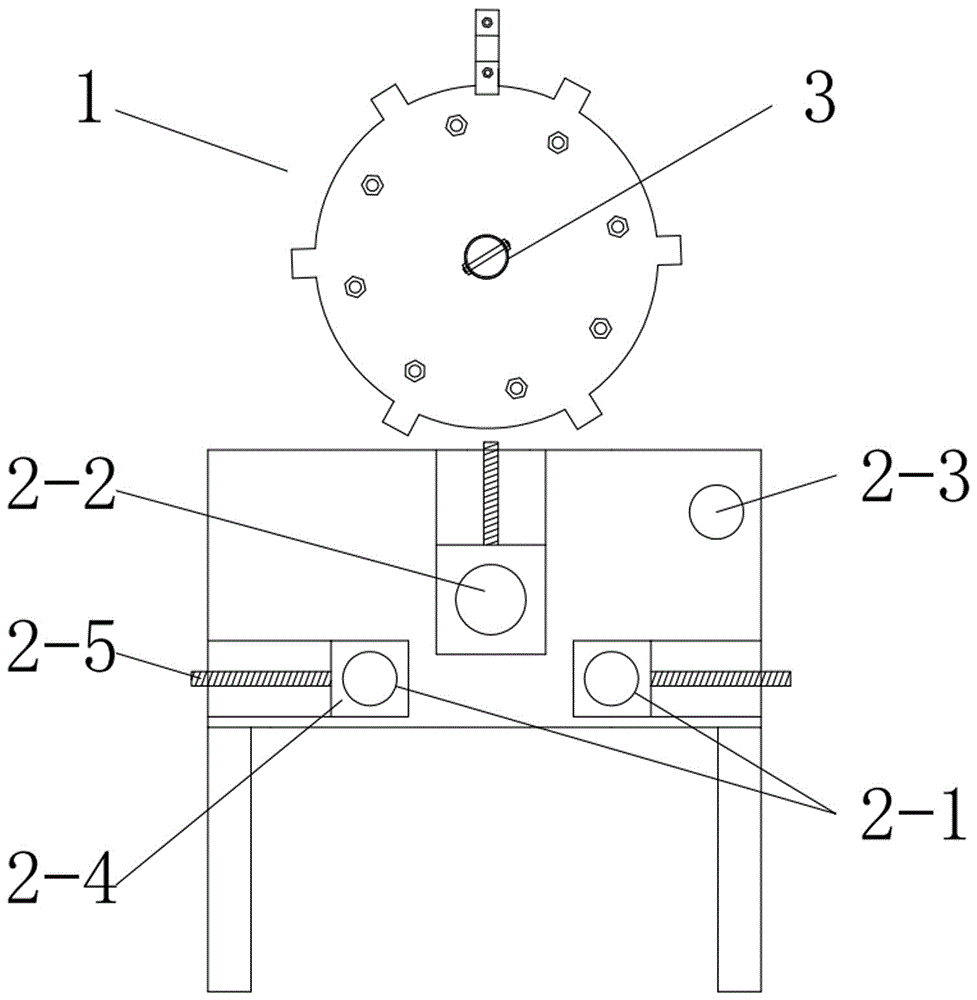

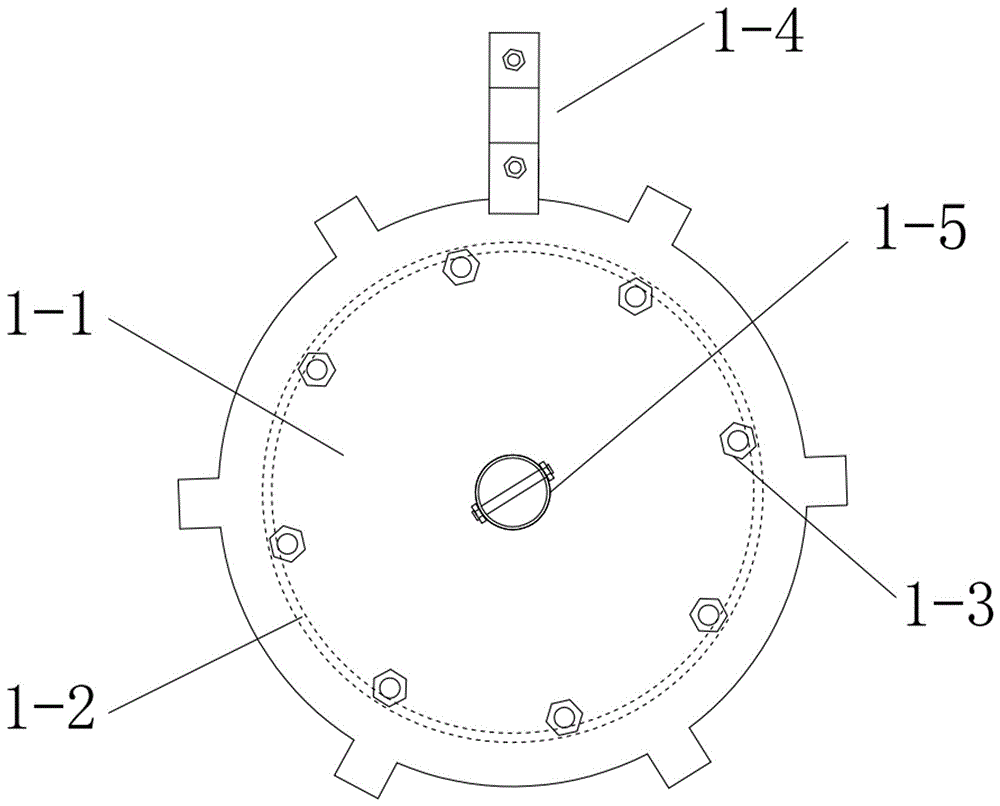

[0035] A copper casing coil machine, see figure 1 , Including the frame and the bending mechanism 2, the coiled tube coil 1 on the frame, the coiled tube coil 1 is equipped with tube head positioning clamps 1-4, and the tube head positioning clamps 1-4 are used for the copper casing The tube head is fixed on the coil tube 1.

[0036] The coil 1 is driven to rotate by the speed reducer 5 with a motor through the rotating shaft 3. The rotating shaft 3 passes through the bearing and is supported by the bearing seat 4 arranged on the frame. There are two bearing seats 4, which are respectively located on the two sides of the coil 1. Side; the bearing seat 4 is fixed to the long hole of the bearing seat 4 bracket on the frame by bolts, and the long hole is perpendicular to the axial direction of the shaft 3. The reducer 5 is fixed on the sliding table 6 of the frame, and can move along the axial direction of the rotating shaft 3 on the surface of the frame through the sliding table 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com