Beological filteration treatment method of wast gas containing hydrophilic and hydrophobic mixed votatile organic matter

A technology of volatile organic compounds and volatile organic compounds, which is applied in the field of waste gas treatment, can solve the problems of low water holding capacity of fillers, large mass transfer resistance, and low temperature of fillers, so as to reduce the loss of nutrients and water, and increase the degradation capacity , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

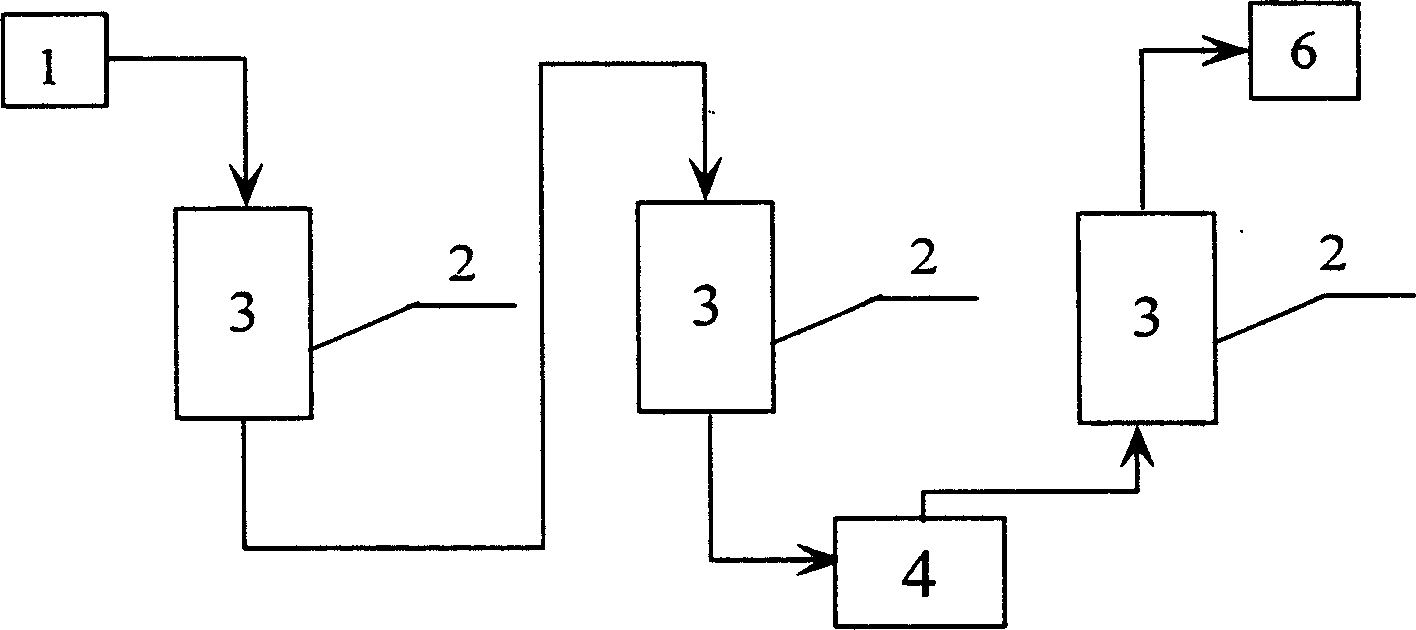

[0042] The average concentration of ethyl acetate and toluene measured in the production workshop of a color printing factory in my country is 1000mg / m 3 and 100mg / m 3 . In the past, the existing technology was used for processing. After three minutes of residence time, the concentrations of ethyl acetate and toluene were respectively 40mg / m 3 and 5mg / m 3, and later changed to the "exhaust gas biological filtration treatment method containing hydrophilic and hydrophobic mixed volatile organic compounds" proposed by the present invention, using a two-stage structural biological filter bed [2], and its dehydration unit [4] is located in two biological Between the filter beds [2], the air inlet [7] of the dehydration unit communicates with the bottom of the first section of biological filter bed [2], while its air outlet [8] connects with the bottom of the second section of biological filter bed [2]. connected at the bottom. Organic waste gas [1] enters from the top of the fi...

Embodiment 2

[0045] In a paint production factory in my country, the production tail gas contains ethyl acetate, isopropanol, ethanol and other water-soluble pollutants, as well as benzene, toluene, xylene, n-hexane and other water-insoluble pollutants. The concentrations are: ethyl acetate 1500mg / m 3 , Isopropanol 2000mg / m 3 , ethanol 2000mg / m 3 , plus some other water-soluble pollutants, the total concentration of water-soluble pollutants in the exhaust gas is 7000mg C / m 3 , The concentration of benzene in the gas is 50mg / m 3 The total concentration of , toluene and xylene is 300mg / m 3 , The concentration of n-hexane is 20mg / m 3 , after treatment, the total concentration of ethyl acetate and isopropanol is required to be less than 500mg / m3 3 , The concentration of benzene is lower than 20mg / m 3 The total concentration of , toluene and xylene is less than 50mg / m3 3 , the use of the original technology did not meet the requirements. Adopt processing method of the present invention,...

Embodiment 3

[0052] A butyl acetate production plant in the eastern part of my country, the pollutants discharged include butyl acetate, acrylonitrile and odorous gas pollutants, and the concentration of total organic carbon is 1500mg C / m 3 The concrete implementation that adopts technique of the present invention is as follows:

[0053] Adopt processing method of the present invention, the selection of its first step biological filter bed and process route is completely with embodiment 1, adopts two sections of biological filter beds [2] and adds dehydration unit [4] between two sections of biological filter beds , the process route is that the exhaust gas at the temperature of 30°C in the workshop enters from the upper part of the first biological filter bed [2] through the air compressor, and enters the dehydration unit from the bottom after the biological filler [3] layer is oxidized and decomposed [4] After condensation, it enters from the bottom of the second biological filter bed [2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com