Water supply jet flow circulating device in waste-heat boiler

A technology of circulation device and jet flow device, which is applied in the field of devices for improving the feed water circulation of waste heat boilers, can solve the problems of short service life of heating tubes, poor cooling effect, low circulation flow rate, etc., and achieve investment and cost reduction, service life extension, production Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

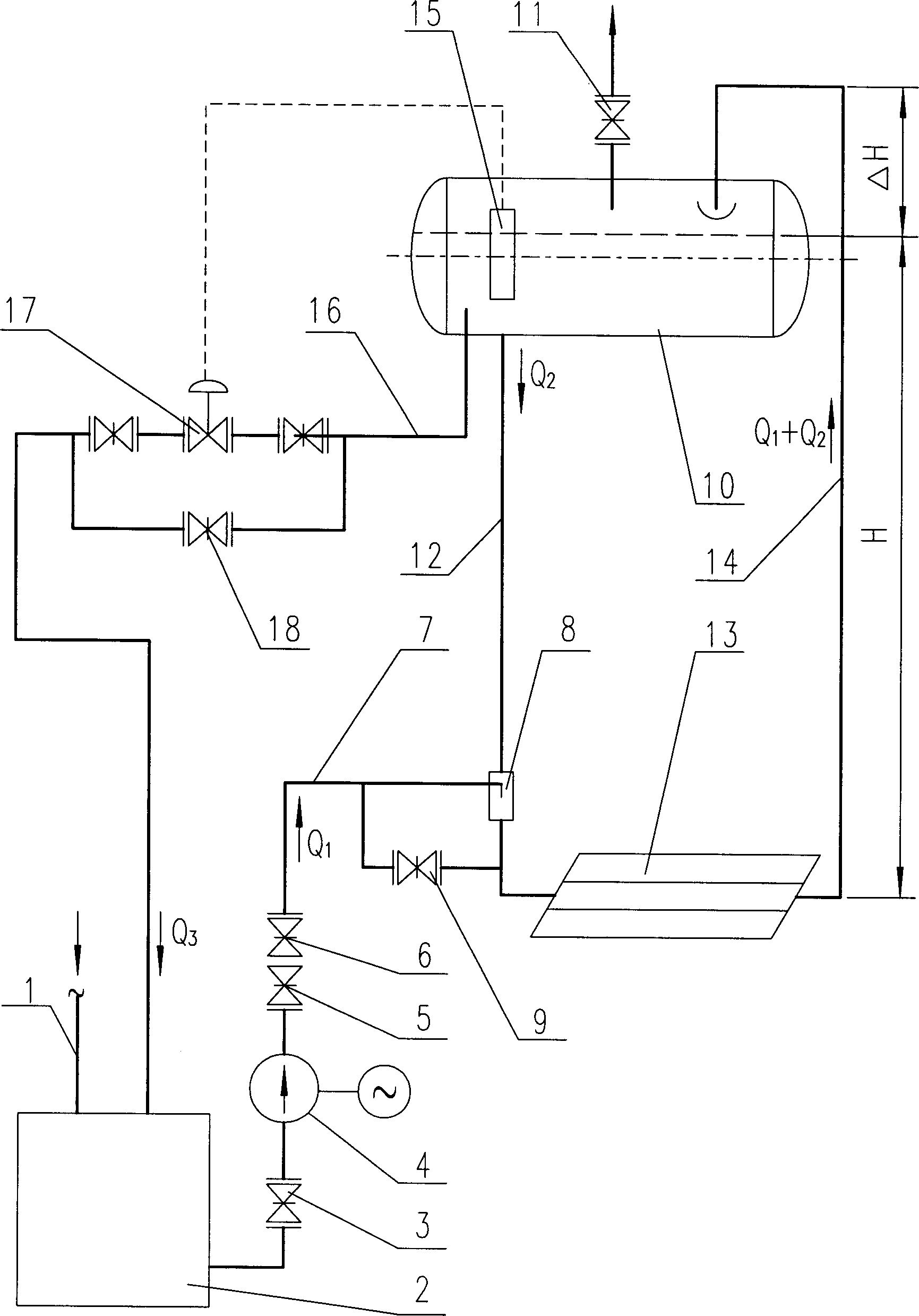

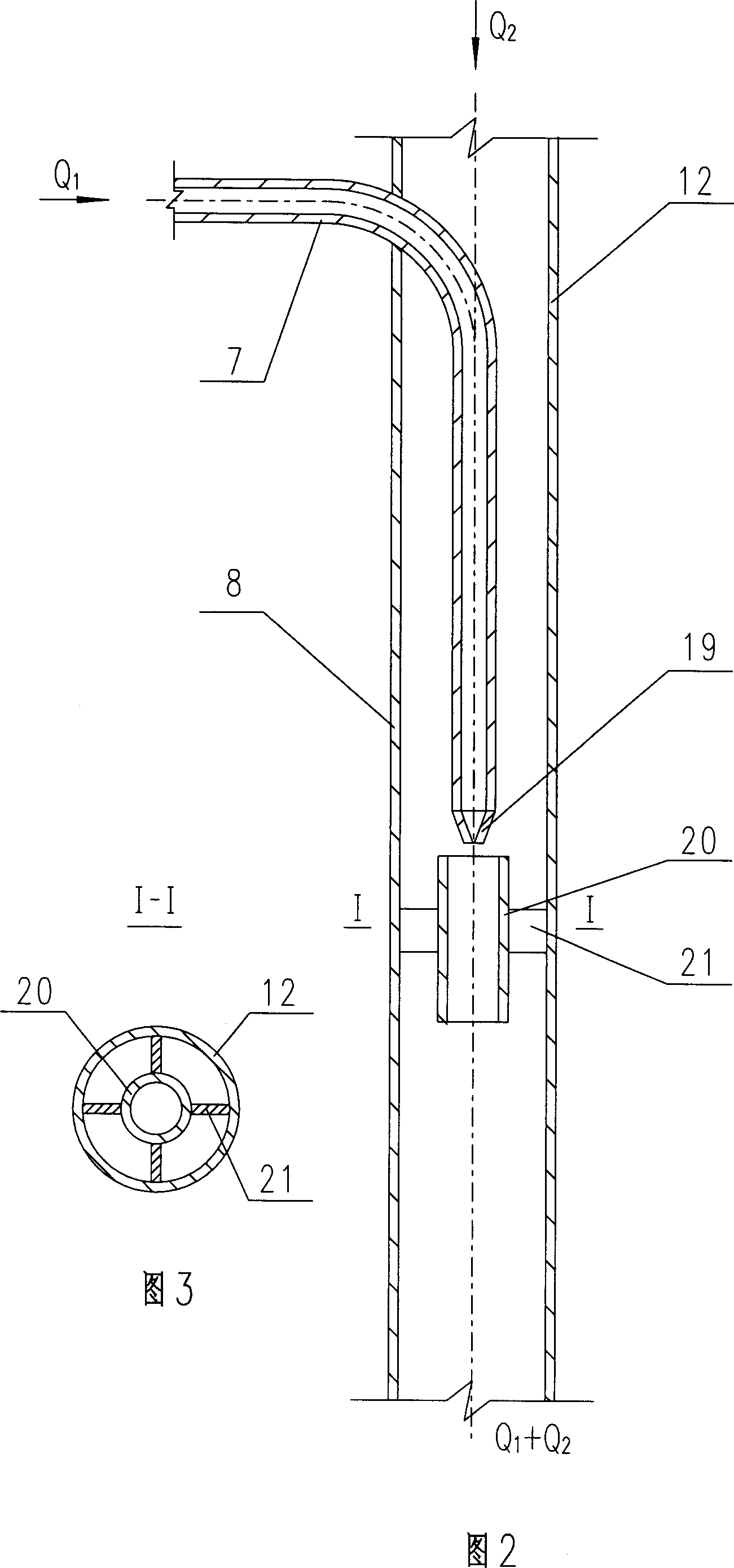

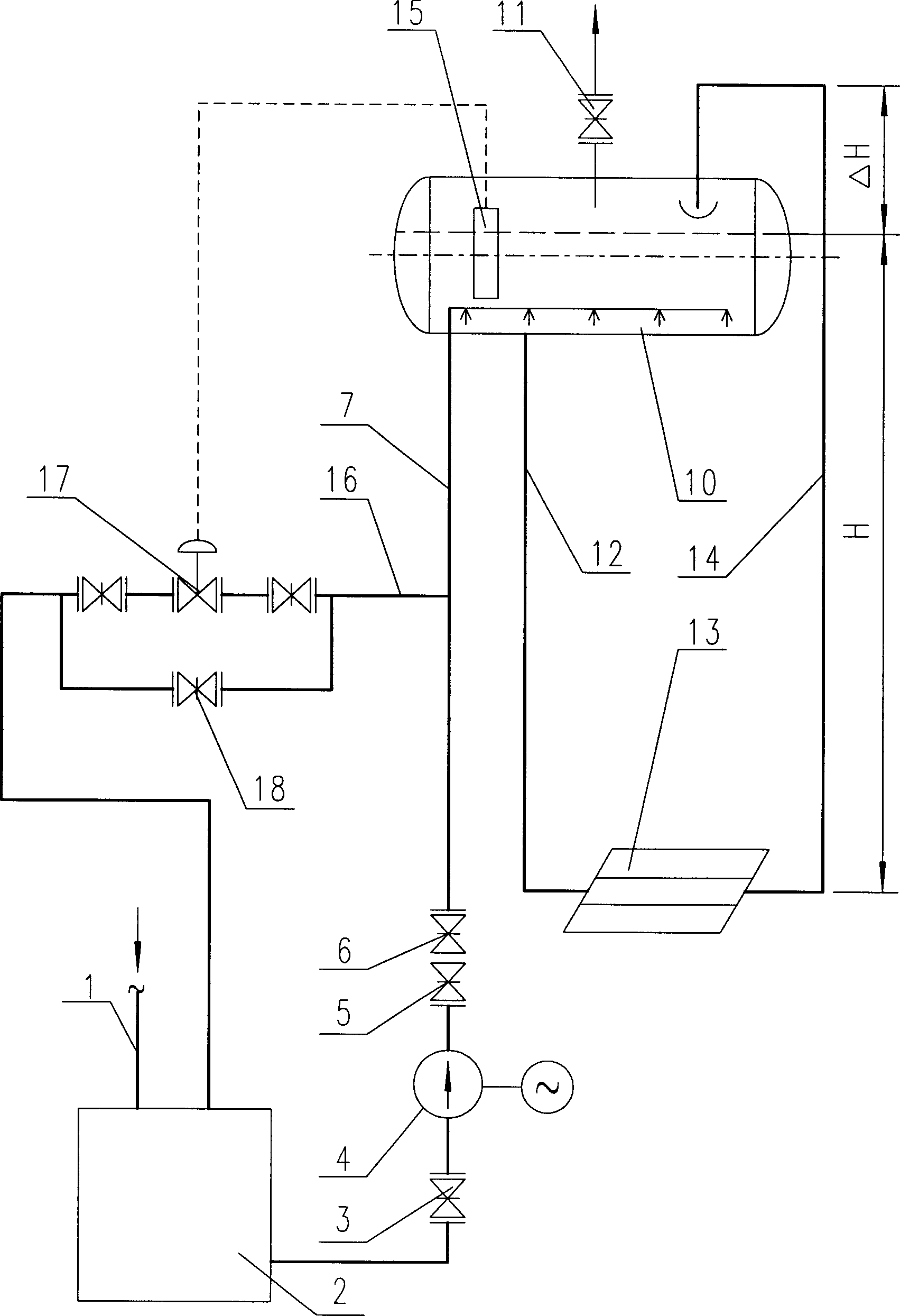

[0015] In Figure 1, the waste heat boiler system of this technology is composed of three parts: the first part consists of soft water inlet pipe 1, soft water tank 2, gate valve 3, feed water pump 4, check valve 5, gate valve 6, water feed pipe 7, jet pump 8 and The bypass valve 9 forms the water supply pipeline; the second part consists of the steam drum 10, the steam outlet valve 11, the descending pipe 12, the heating pipe 13, and the ascending pipe 14; the third part consists of the remote water level gauge 15, the return pipe 16, The water level regulating valve group 17 and the bypass valve 18 form the return water pipeline. It can be seen from Fig. 1 that the descending pipe 12 and ascending pipe 14 of the steam drum 10 are connected with the heat receiving pipe 13 to form a U-shaped connection. The center of the heat pipe 13 is higher than the height H, and the water surface of the steam drum 10 is ΔH from the highest point of the riser 14, which is ≈0.3m in this techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com