Silver tin-oxide zinc-oxide alloy electric contact and its production process

A silver tin oxide and production process technology, applied in the field of electrical contacts, can solve the problems of high cost, poor production and processing characteristics, and lack of reprocessing performance of bimetallic composite rivets, so as to achieve the effect of avoiding pollution and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

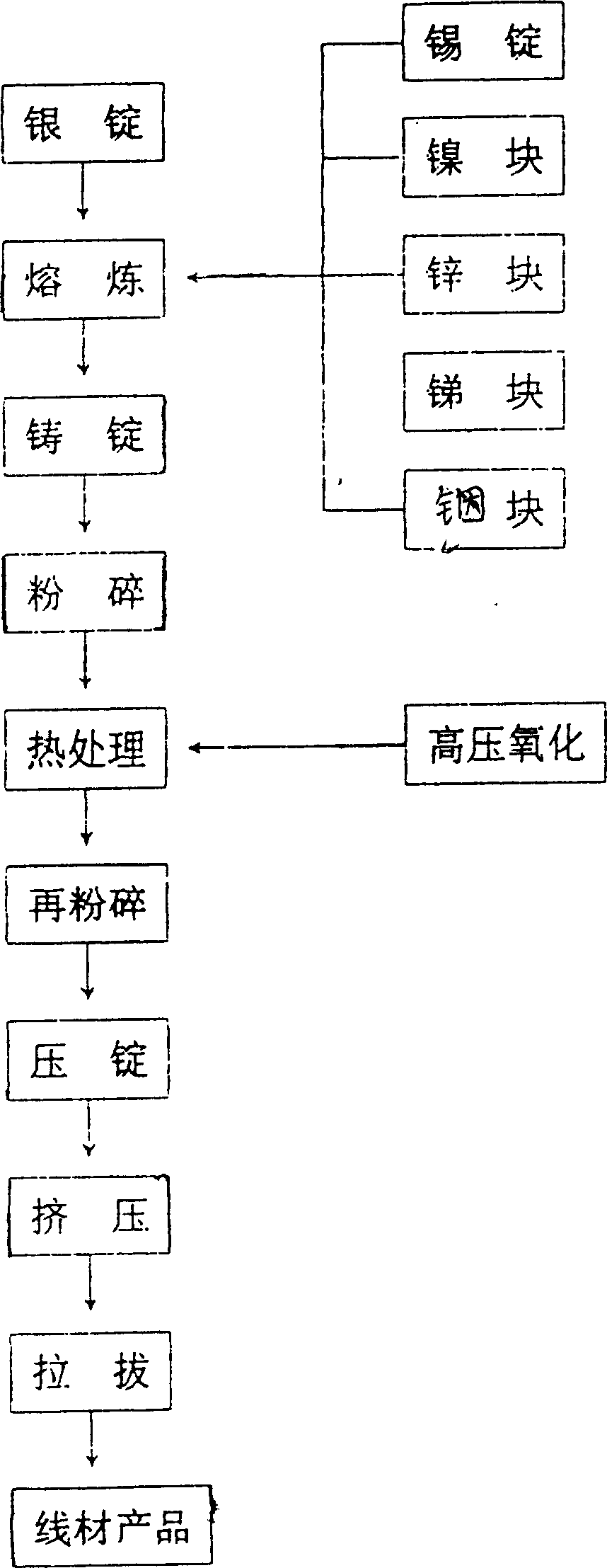

[0022] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

[0023] Example 1: Weigh 14.27Kg silver ingot, place it in a medium frequency induction furnace to melt, then add 0.8Kg tin and 0.48Kg zinc in turn, after homogenization, clear the slag and cast it into a round ingot, cut off the gate and remove surface impurities, cut Break it into pieces, put it into a high-pressure container and heat it to 760-820°C, inject 6Kg / cm2 of oxygen, keep it warm for 36 hours, then process the oxidized pieces into small pieces with a punching machine, put them into a steel mold and pressurize them into Φ68mm For a round ingot with a length of 250mm, the formed round ingot is extruded at a high temperature of 820-860°C into a Φ4.0 rod, and then hot-drawn into a wire product of Φ1.12-3.9mm.

[0024] As above, 1.6Kg tin and 0.96Kg zinc were added respectively, and the same result was obtained.

[0025] Example 2: Weigh 14.64Kg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com