Device for interference detection device of surface precision of large-diameter concave aspheric lens

A technology of interference detection and aspheric mirror, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to accurately measure the surface shape of large-diameter concave aspheric optical elements and large wave aberration, so as to save labor costs, The effect of small residual aberration and easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

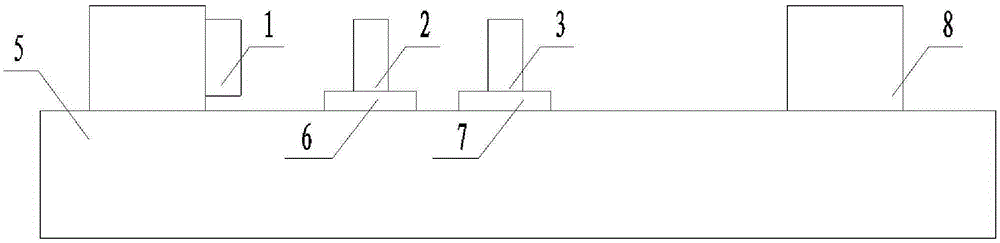

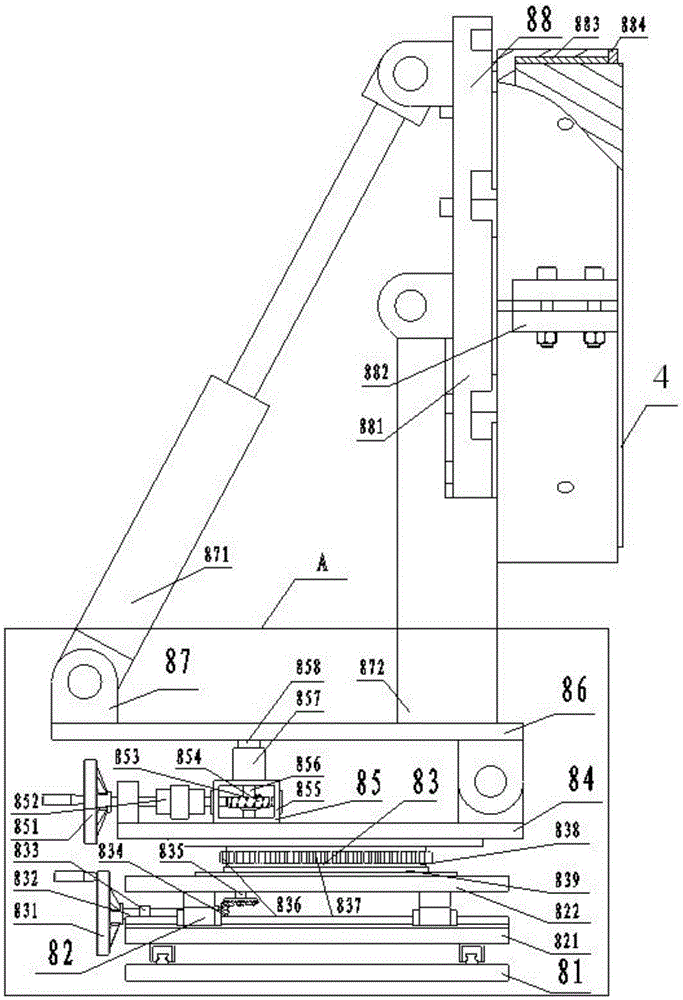

[0024] Laser interferometer 1, compensation lens one adjustment bracket 6, compensation lens two adjustment bracket 7, aspheric mirror adjustment device 8 are placed on the vibration isolation platform 5, compensation lens one 2 is fixedly connected with compensation lens one adjustment bracket 6, compensation lens two 3 It is fixedly connected with the second adjustment bracket of the compensation lens.

[0025] Build the optical path device according to the interference principle, adjust the relative positions of compensation lens 1 2, compensation lens 2 3, compensation lens 1 adjustment bracket 6, compensation lens 2 adjustment bracket 7 and aspheric mirror adjustment device 8 to complete the detection process of the entire concave aspheric mirror.

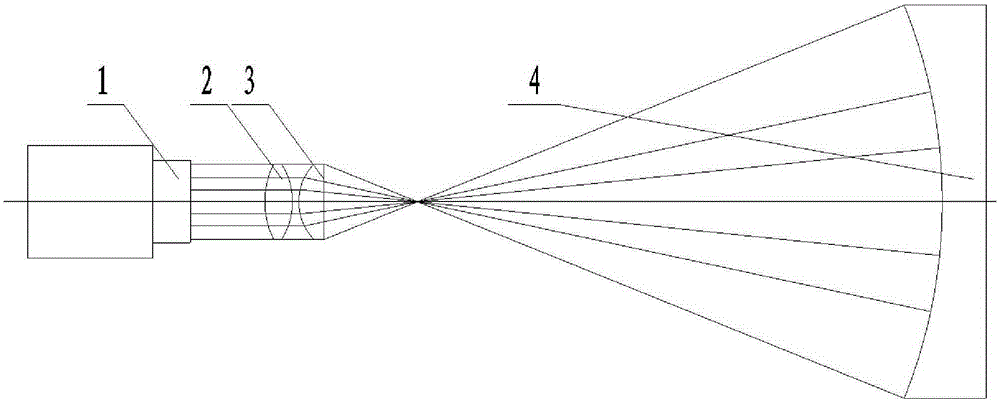

[0026] refer to figure 1 , the schematic diagram of the optical path of the detection principle of the present invention includes a laser interferometer 1, a compensation lens 2, a compensation lens 2 3, and a measured aspheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com