Battery and electric double-layer capacitor

A technology of batteries and current collectors, applied in the manufacture of double layer capacitors, multiple hybrid/electric double layer capacitors, and hybrid/electric double layer capacitors, etc., to achieve the effect of small equipment, prevention of terminal corrosion, and less production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

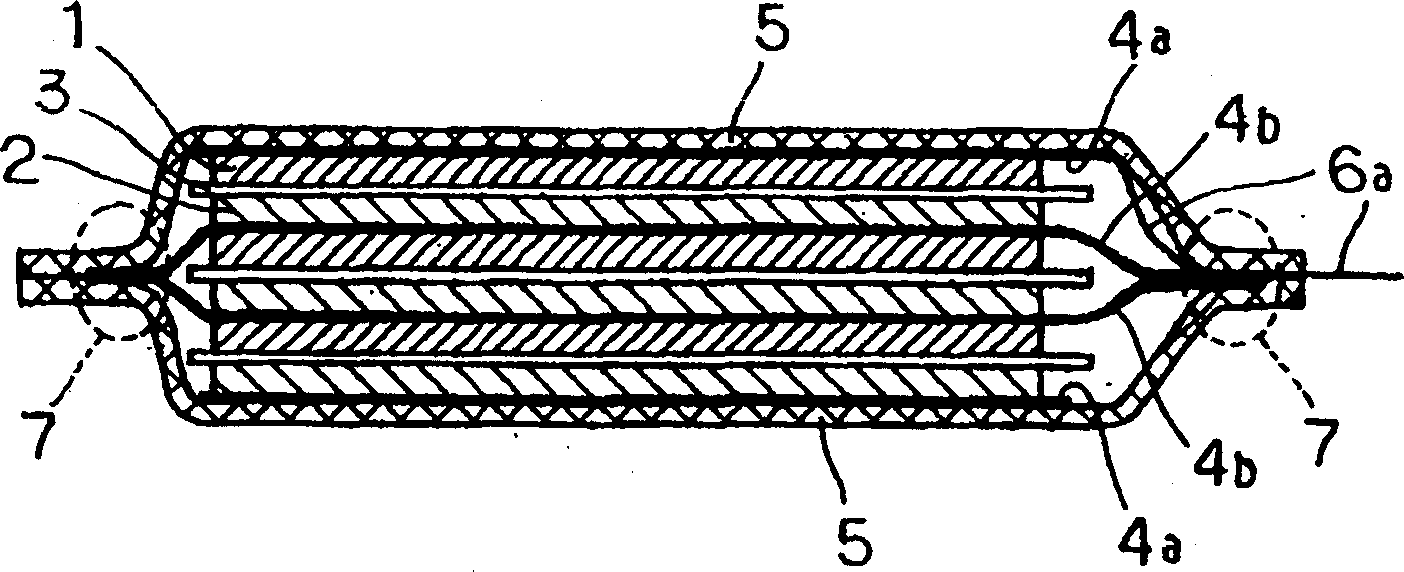

[0050] In this example, if figure 2 The battery shown was fabricated with a laminated structure of three elementary cells connected in series.

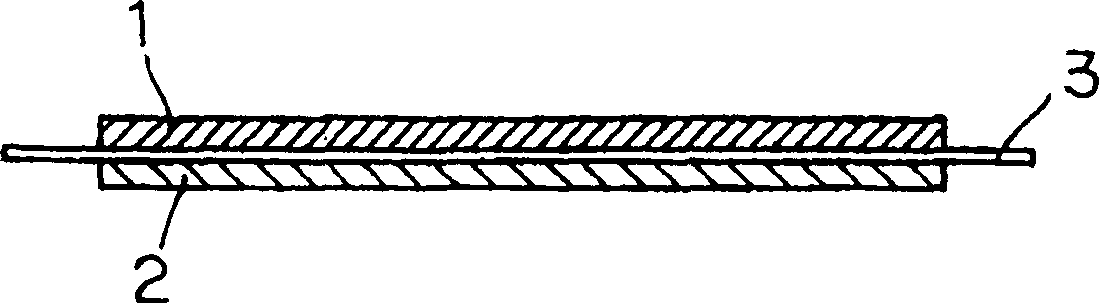

[0051] For the cathode 1, through the indole trimer represented by the chemical formula (1) (R at the 5-position of the indole cell is -CN and the remaining R is -H: 5-cyanoindole trimer ) to the cathode active material, add conductor auxiliary material and binder, stir or mix by mixer to form electrode powder, put 0.5 g of powder into mold and heat treatment to form 10cm 2 solid electrode.

[0052] For the anode 2, by adding the conductor auxiliary material in the anode active material of polybenzoquinoxaline represented by chemical formula (2), stirring or mixing by a mixer to form an electrode powder, by putting 0.5 gram of powder into molded and heat-treated to form a 10cm 2 solid electrode.

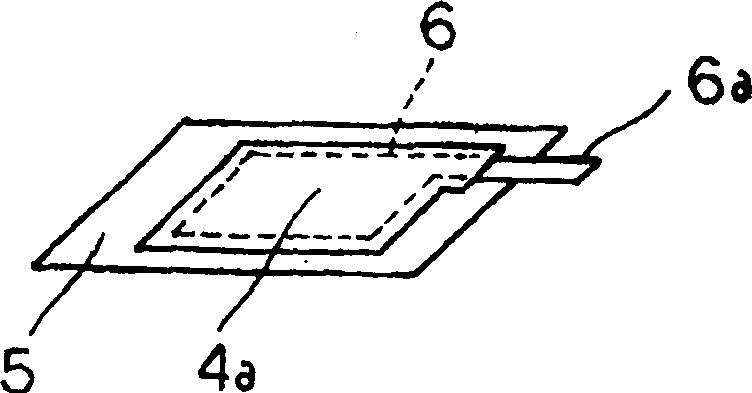

[0053] The current collectors 4a, 4b are conductive rubber thin layers and the laminated thin layer 5 is formed by laminating aluminum...

Embodiment 2

[0061] The battery manufactured in this example is as described in Example 1 except that the weight of the cathode and the anode are both 1.0 g.

[0062] The volumetric efficiency of the battery of Example 2 was 87.5%. The ESR of the battery is 120m. The time taken until the sealing process in the production process of the battery was 20 minutes. In the configuration of the present embodiment, volumetric efficiency is improved; ESR of a single cell can be reduced; and production time can be reduced.

Embodiment 3

[0064] The battery fabricated in this example was as described in Example 1, except that ten basic single cells were laminated in series and sealed.

[0065] The volumetric efficiency of the battery of Example 3 was 90.5%. The ESR of the battery is 200m. The time taken until the sealing process in the production process of the battery was 20 minutes. In the configuration of the present embodiment, volumetric efficiency is improved; single cell ESR can be reduced; and production time can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com