Machine for forming rod of prefabricated optical fibre rod by induction heating

An optical fiber preform and induction heating technology, which is applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of affecting the quality of optical fiber preform, insufficient heating efficiency, and high dust volatilization, and achieves improved processing accuracy and SiO2 The effect of less dust volatilization and strong safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

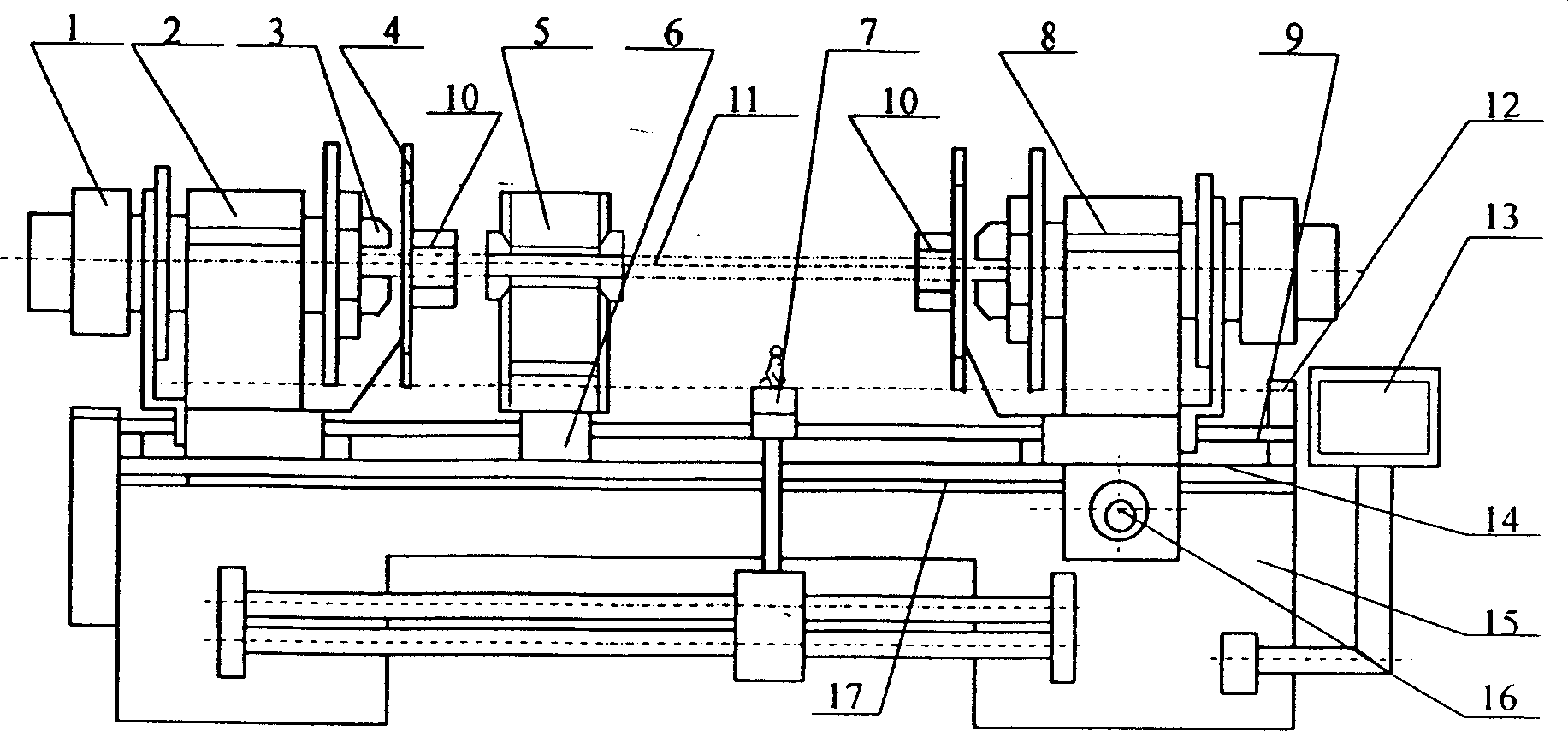

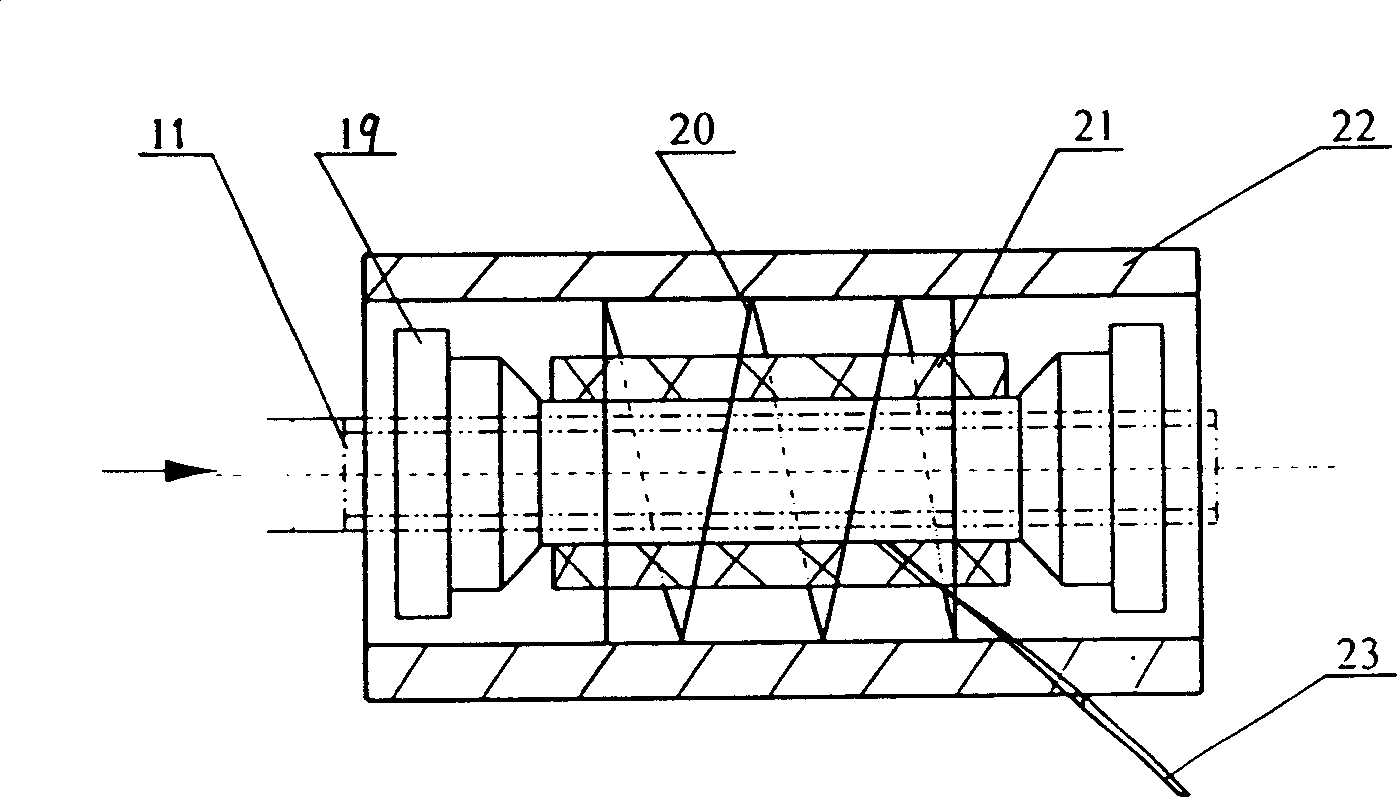

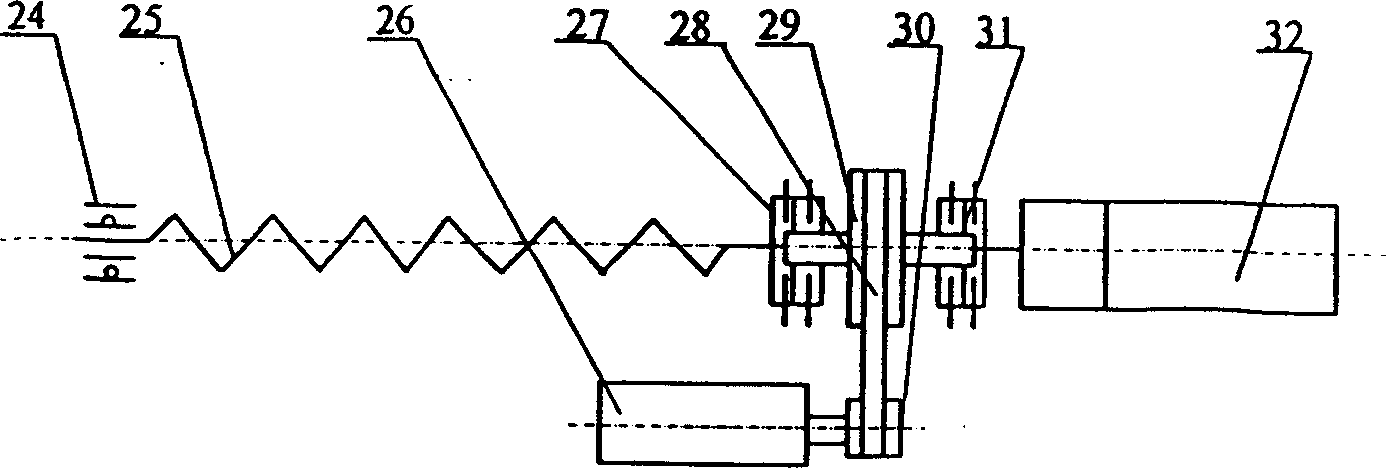

[0014] Further illustrate the embodiment of the present invention below in conjunction with accompanying drawing, comprise lathe bed 15, be equipped with fixed headstock 2 on one side above lathe bed, the other side is installed with movable headstock 8, fixed headstock and movable main shaft The box is connected through a synchronous drive mechanism 12, and the synchronous drive mechanism includes a main motor 33, a synchronous pulley 36 connected with the main motor, a toothed transmission belt 35 and a main shaft pulley 34 connected with the fixed headstock main shaft. The mobile synchronous pulley 38 on the mobile headstock side, the toothed transmission belt 39 and the main shaft pulley 40 linked with the main shaft of the mobile headstock, the synchronous pulley 36 and the mobile synchronous pulley 38 are connected by the spline shaft 37 and rotate synchronously ,Such as Figure 4 As shown; both the fixed spindle box and the movable spindle box are equipped with a chuck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com