Multi-point clamping device and robot for picking up articles

A multi-point, gripper technology, applied in the direction of chucks, manipulators, program-controlled manipulators, etc., can solve the problems of attacking the enthusiasm of processing manufacturers to improve production lines, affecting production efficiency and economic benefits, and high cost. Simple and reliable results in a short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

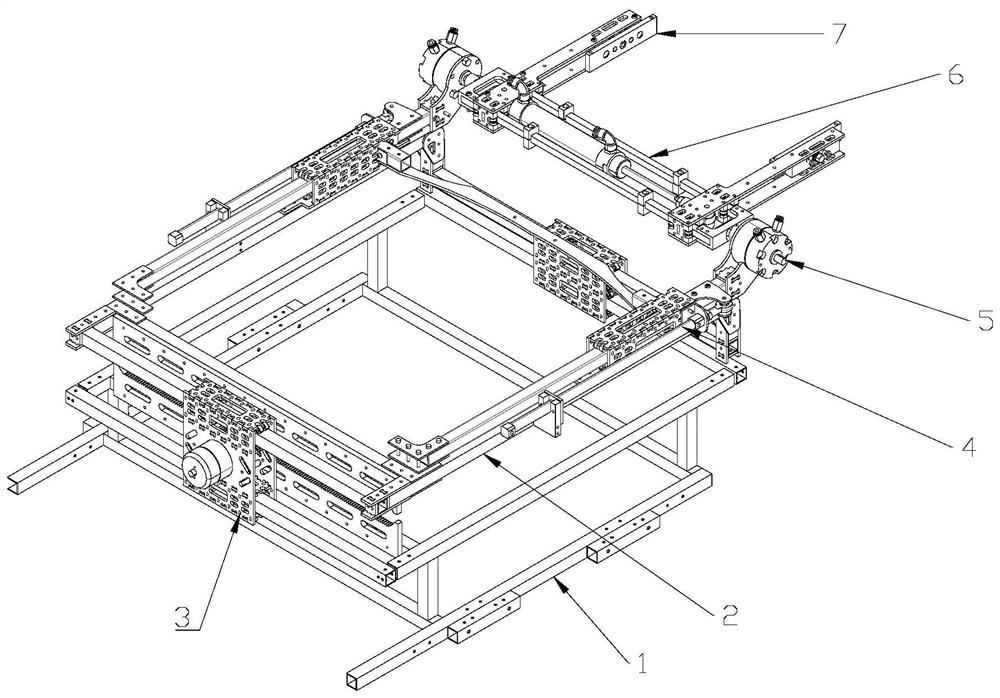

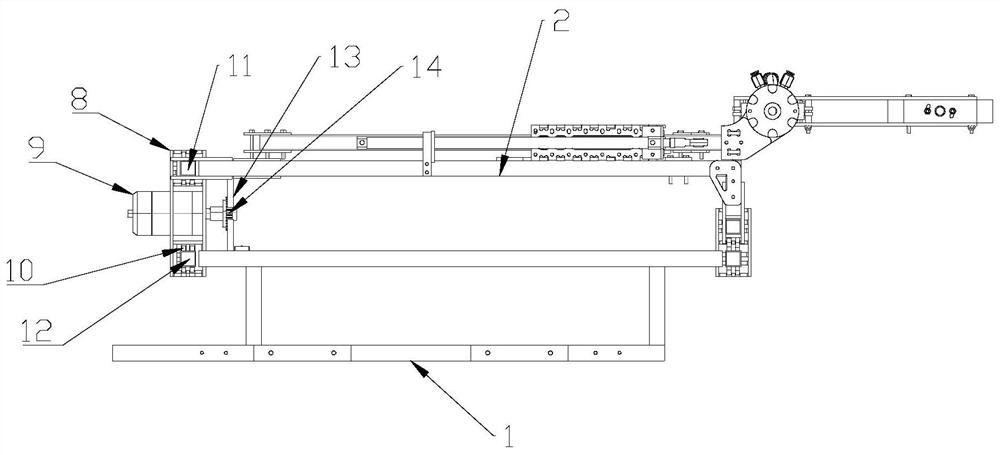

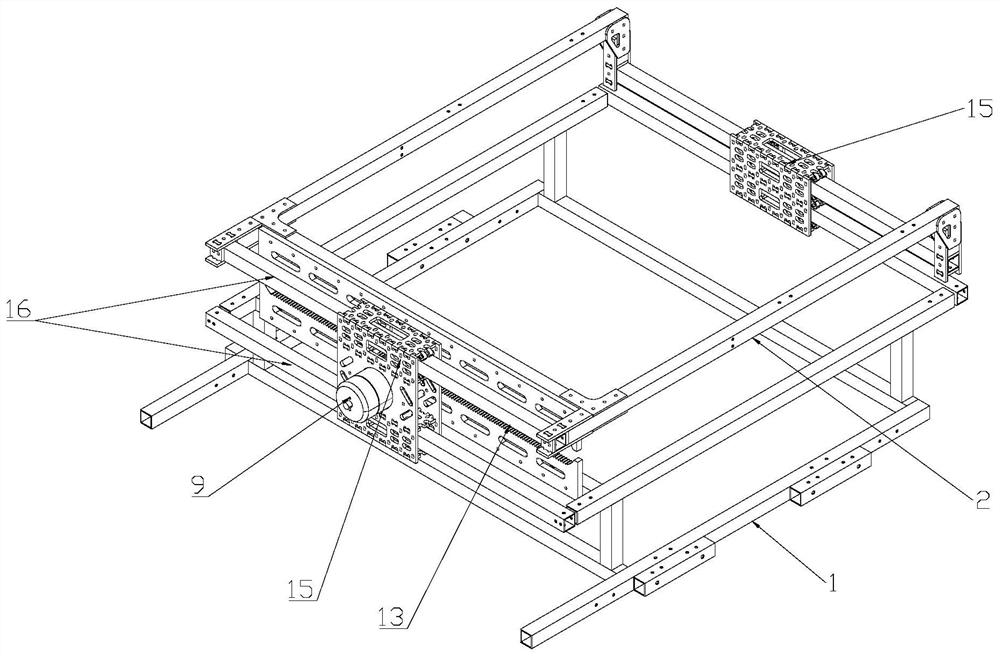

[0031] A multi-point clamping device in this embodiment includes an upper frame, a lower frame, a left and right sliding mechanism, a front and rear telescopic mechanism, a front and rear turning mechanism, a left and right opening and closing mechanism, and a clamping mechanism; the left and right sliding mechanism includes a double-layer pulley , The left and right sliding parts that drive the upper frame to slide in the left and right direction relative to the lower frame; The frame is connected to the left and right sliding parts, and the lower frame is connected to the left and right sliding parts; the front and rear telescopic mechanisms are installed on the upper frame, the front and rear turning mechanisms are installed on the front and rear telescopic mechanisms, and the left and right opening and closing mechanisms are installed on the front and rear turning mechanisms. The mechanism is installed on the left and right opening and closing mechanisms.

[0032] In actual ...

Embodiment 2

[0042] A robot for picking up objects in this embodiment includes a receiving mechanism and a multi-point gripping device, and the multi-point gripping device is located above the receiving mechanism.

[0043] The working process of the robot for picking up items in this embodiment: according to the position of the desired item to be picked, enter the control program. In the initial state, the upper frame slides to the middle position through the left and right sliding mechanism, and the stopper triggers the photoelectric switch to control the motor to stop. drive. In the working state, through the position detection mechanism and the left and right sliding mechanism, the upper frame is controlled to slide in the three positions in the left and right directions, so that the clamping mechanism can clamp the items in these three positions; if the items that are closer to the upper frame , the left and right sliding mechanism drives the upper frame to move left and right, the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com