Conductive silicon oxide powder, its mfg. method and negative electrode material of nonaqueous electrolyte secodary battery

A technology of silicon oxide powder and non-aqueous electrolyte, which is applied in the direction of non-aqueous electrolyte battery electrodes, non-aqueous electrolyte batteries, conductive materials, etc., and can solve the problems of limited charge/discharge capacity, insufficient conductivity, and inability to withstand practical applications. , to achieve the effect of improving cycle performance and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

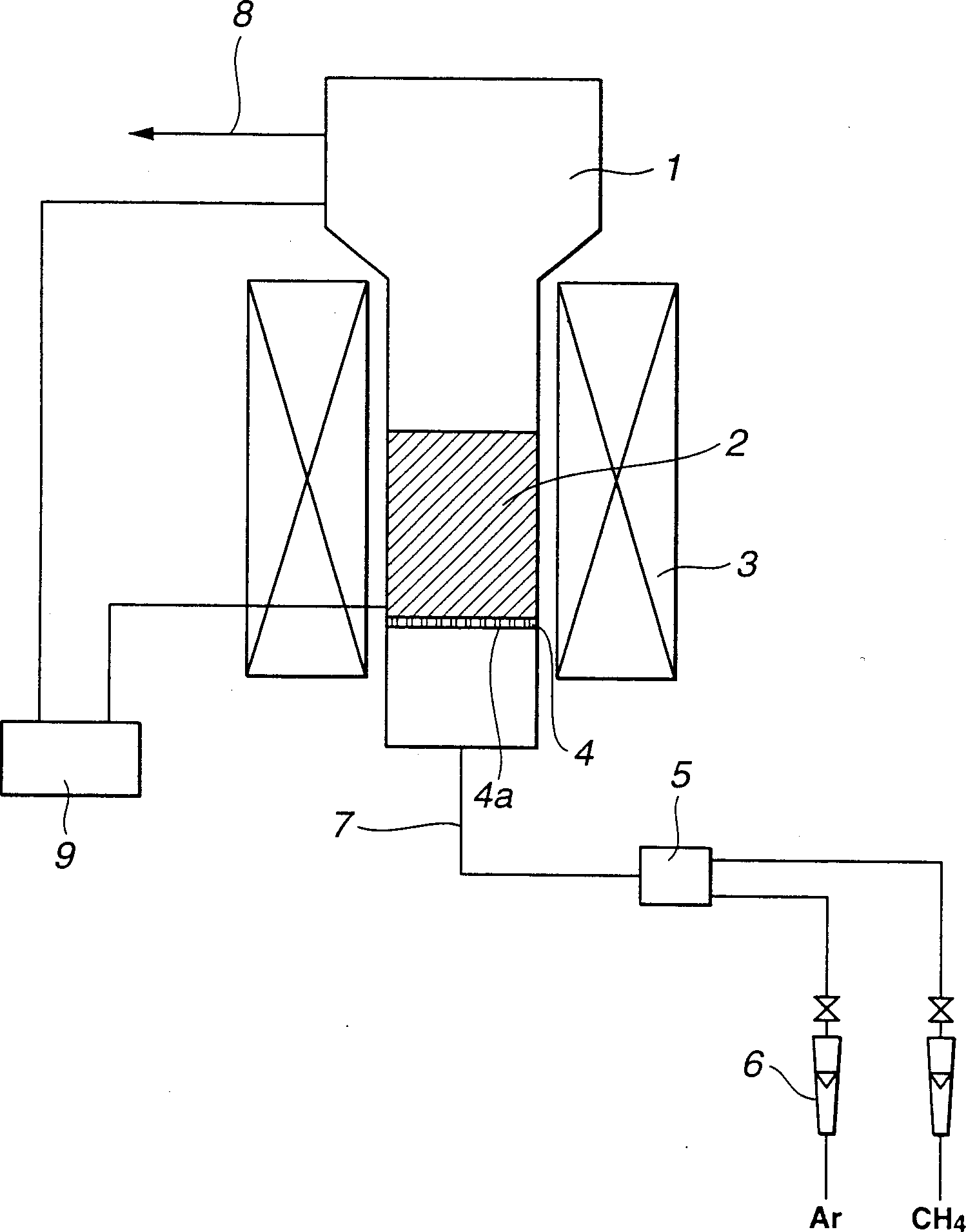

[0031] use figure 1 The batch fluidized bed reactor system shown in , describes the conductive silica powder prepared by the following method. figure 1 The system comprises a fluidized bed reactor 1 with a gas distributor 4 forming a fluidized bed 2 thereon, a heater 3 surrounding the reactor, and a gas delivery line 7 with a gas stirrer 5 and a flow meter 6 . pumped by suitable means, measured by flow meter 6, mixed Ar and CH in gas stirrer 5 4 Gas, the gas mixture is delivered from the gas stirrer to the reactor 1 through the delivery line 7 and injected into the reactor chamber through a plurality of orifices 4 a in the gas distributor 4 . The silicon oxide powder is allowed to enter the reactor chamber, and the gas is injected to form a fluidized bed 2 of the silicon oxide powder. The reactor 1 has a gas release line 8 and a differential pressure gauge 9 .

[0032] Preparation of pristine silica powder

[0033] For silica powders of equal molar ratio (BET surface area ...

example 2

[0044] Preparation of pristine silica powder

[0045] For silica powders of equal molar ratio (BET surface area = 200m 2 / g) and ceramic grade metal silicon powder (BET surface area = 4m 2 / g) of the powder mixture was heat-treated at 1,350°C in a hot vacuum atmosphere of 0.1 Torr. The resulting SiO gas is deposited on a water-cooled stainless steel substrate. The precipitate was collected and ball milled in hexane. Properly adjust the grinding time to generate D 50 = 0.8 μm silicon oxide powder (SiOx powder).

[0046] The silicon oxide powder obtained is SiOx powder, wherein x=1.05, and the electric conductivity measured by four-terminal method is 3 * 10 -9 S / m. by solid-state NMR ( 29 SiDD / MAS) when analyzing SiOx powder, the spectrum includes two separate peaks, a broad peak (A1) centered at -70ppm and another broad peak (A2) centered at -110ppm, the area ratio of these peaks is A1 / A2 is 0.68.

[0047] Preparation of conductive silicon oxide powder (CVD treatment) ...

example 3

[0056] In addition to making the change in the fluidized bed heat treatment of Example 2 to 3.3NL / minAr gas and 0.6NL / minCH 4 Gas (Ar gas and CH 4 Gas ratio is 11:2), repeat the procedure of Example 2. The conductive silicon oxide powder thus obtained has a 5×10 -1 S / m conductivity with 10.3 wt% carbon deposited thereon. Using this conductive silicon oxide powder, a battery was constructed and tested in the same manner as in Example 2. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com