Corrosion inhibition method for non-passive metal and boiler

A corrosion-inhibiting, metal-body technology, applied in corrosion-reducing boiler components, chemical instruments and methods, boiler cleaning devices, etc., capable of solving problems such as corrosion and damage of heat transfer tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

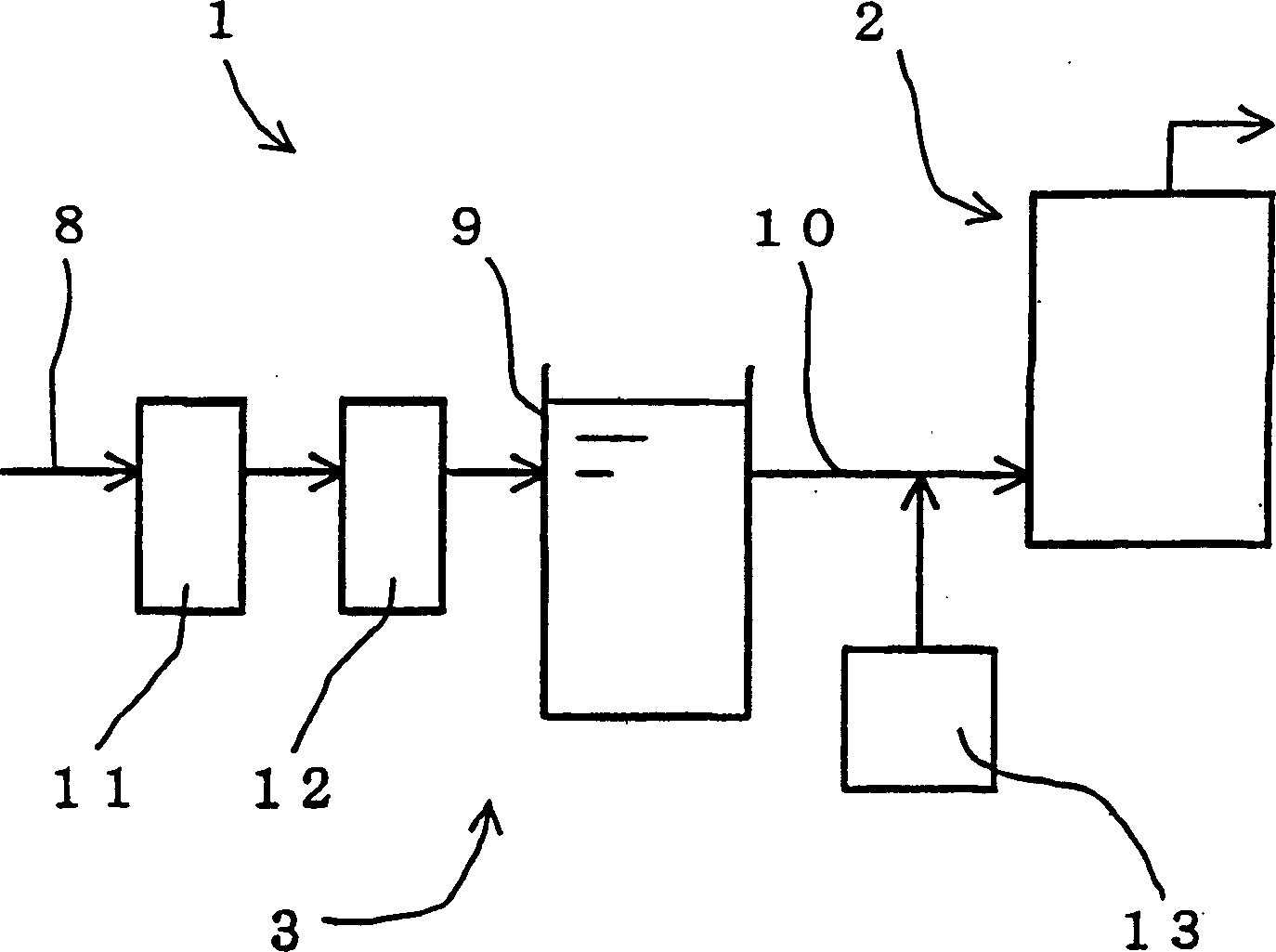

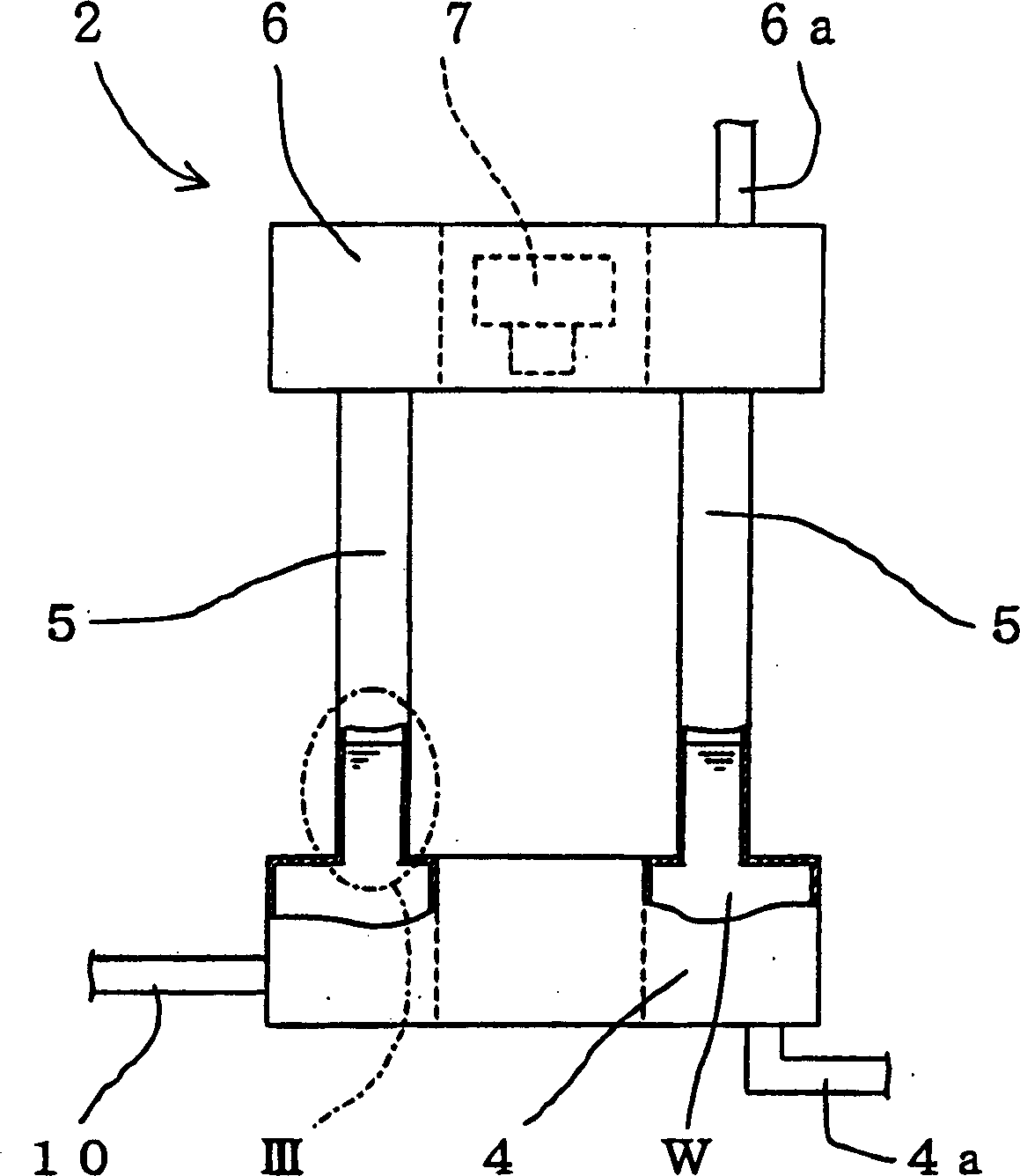

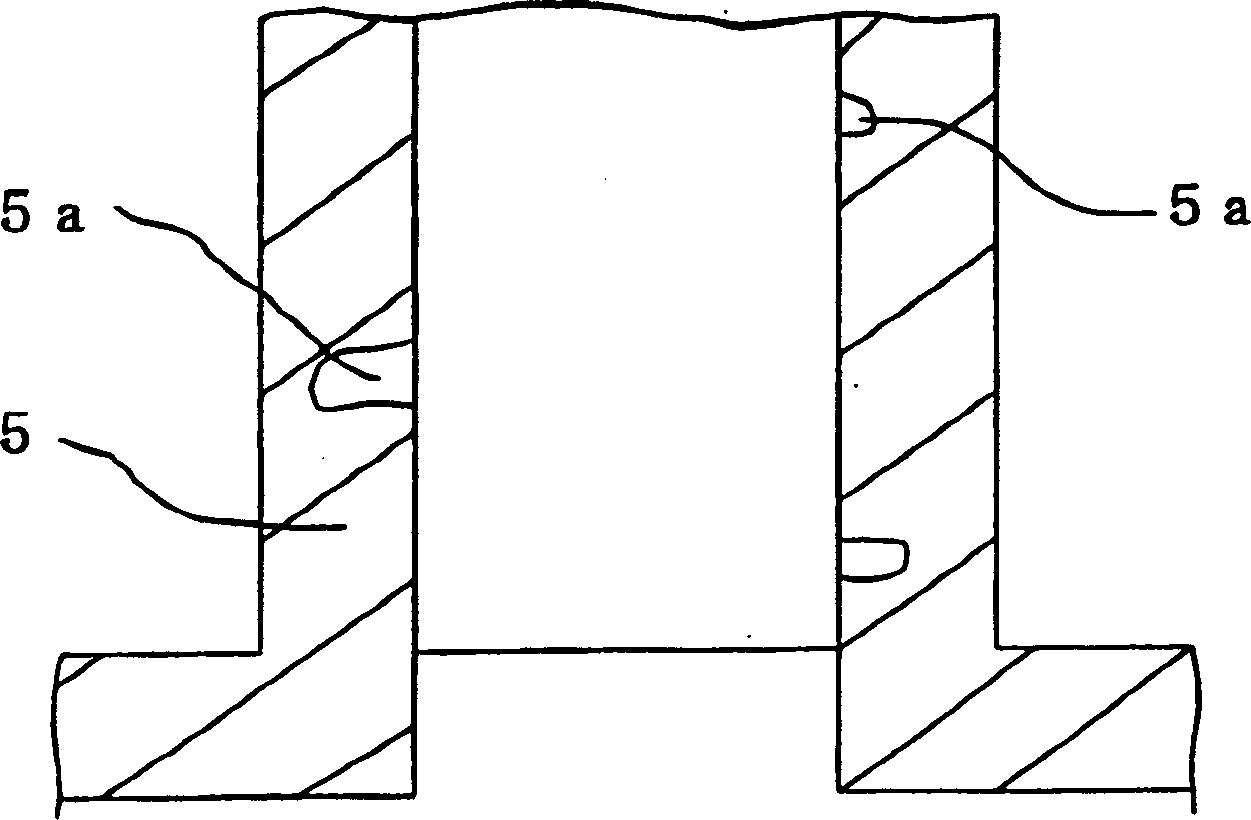

Method used

Image

Examples

Embodiment

[0049] While supplying feed water with different concentrations of citric acid, it was operated to supply the boiler manufactured by the patent applicant company. At this time, adjust the concentration ratio of boiler water so that: the M alkalinity (acid consumption (PH4.8)) of boiler water is 300mg CaCO 3 / l, chloride ion concentration 200mg / l, sulfate ion concentration 400mg / l, dissolved oxygen concentration 4.0ppm and citric acid concentration 70mg / l. The pH of the boiler water is adjusted to 11.5% by properly injecting an aqueous sodium hydroxide solution into the feed water. The operating conditions of the boiler are set as follows: the operating time is 48 hours, the operating pressure is 0.29MPa and the feed water temperature is 50°C.

[0050] The relationship between the concentration of citric acid in the boiler water and the maximum depth of corrosion pits (μm) generated in the heat transfer tubes was investigated for boilers operated under the above conditions. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com