Vacuum treatment method of molten steel dephosphorus

A technology for vacuum treatment and molten steel, applied in the field of vacuum refining, can solve the problems such as difficulty in independent regulation of oxygen/powder material flow ratio, large loss of processing time or molten steel temperature, inability to use cheap bulk raw materials, etc. Wide range of addition rates and reduced phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

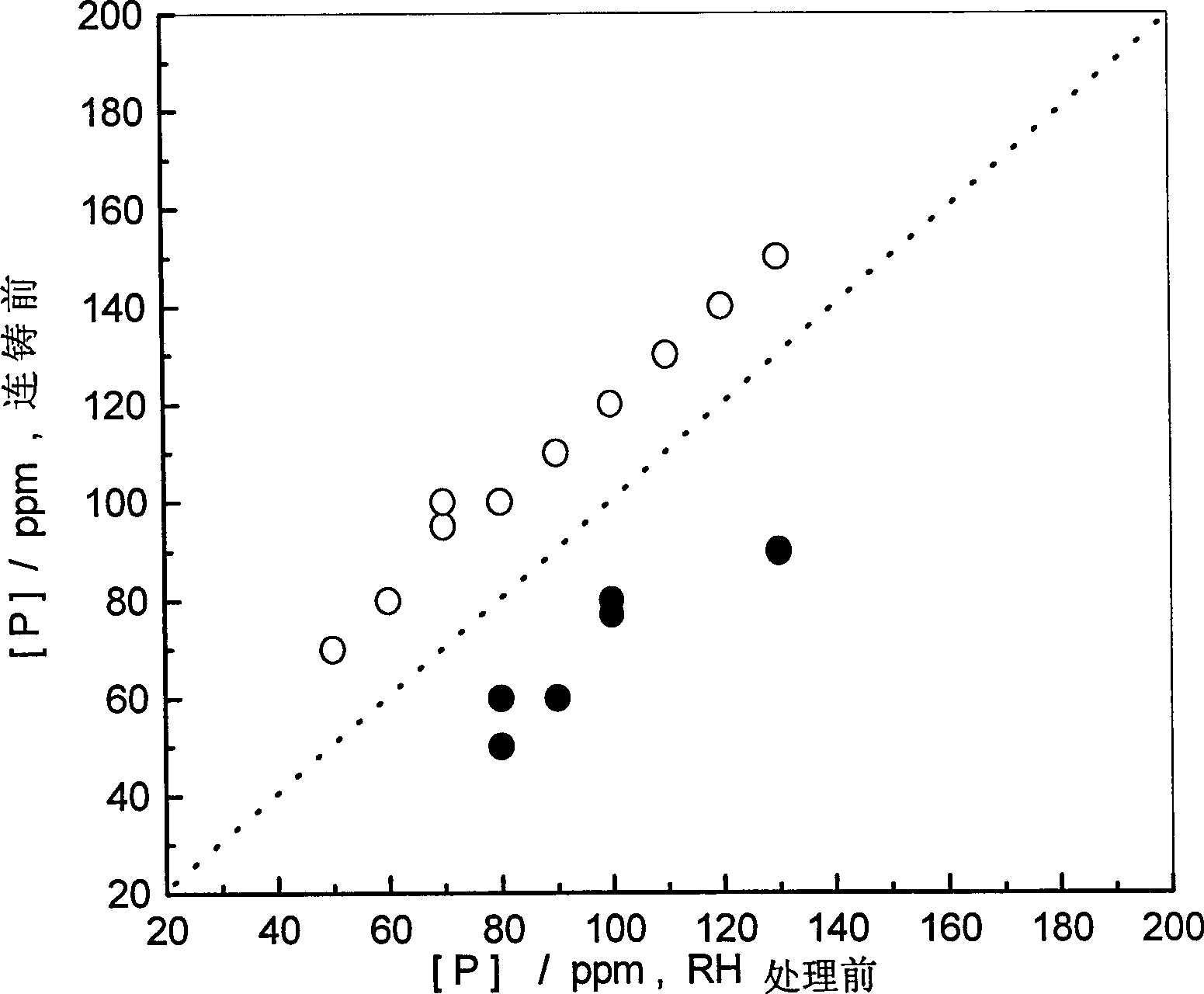

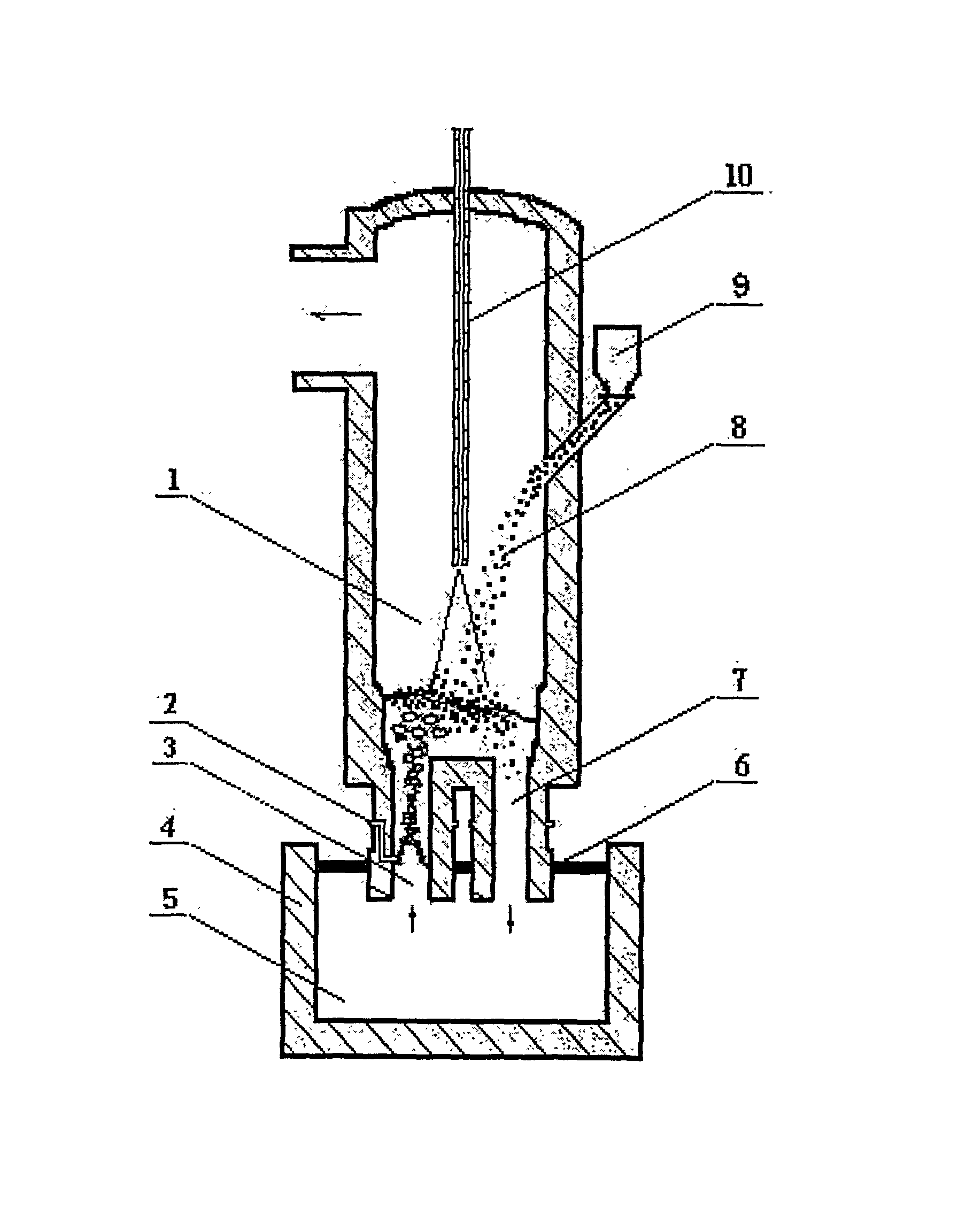

[0024] Example 1: In figure 1 On the shown RH vacuum degassing device, 4 furnaces of weakly deoxidized steel and 2 furnaces of aluminum and silicon killed steel were processed by the method of the present invention. Since the amount of flux added depends on the initial phosphorus and target phosphorus content and processing time of molten steel, therefore, The range of technical parameters such as oxygen and flux is given in the following process conditions:

[0025] Mass flux composition 60% active lime and 40% fluorite;

[0026] Powder composition 70% active lime and 30% fluorite;

[0027] Adding rate 100~120kg / min;

[0028] Oxygen injection volume per kg flux injection 0.06~0.260Nm 3 oxygen;

[0029] Addition amount of flux: 2~5kg flux per ton of molten steel;

[0030] Spray gun position 2-4m above the bottom of the vacuum chamber;

[0031] Ladle slag composition (mass%) (CaO / SiO 2 ) / Al 2 o 3 Greater than 0.2;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com