Low-alloy steel hot-rolling coil plate of which yield strength is more than 345Mpa, and preparation method of low-alloy steel hot-rolling coil plate

A low-alloy steel and yield strength technology, which is applied in the field of hot-rolled low-alloy steel coils with a yield strength of 345Mpa or more and its preparation, can solve the problems of uneven performance of steel strips and difficulty in precise control of hot-rolling temperature, and achieve Reduce smelting costs, improve center segregation, and prevent the tube from being out of round

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. The chemical composition percentage of steel is as follows:

[0026] C: 0.16%, Si: 0.14%, Mn: 0.49%, P: ≤0.021%, S: ≤0.011%, Ti: 0.043%, and the rest is Fe element and unavoidable impurities.

[0027] 2. The production process of Q345B low-alloy hot-rolled coil, taking the specification of 5.75mm×1150mm as an example:

[0028] (1) Production process

[0029] KR hot metal pretreatment-BOF-LF-CC-slab heating-rough rolling-finish rolling-coiling;

[0030] (2) Preparation process

[0031] KR molten iron pretreatment controls the sulfur content of the molten iron below 0.010%, and the temperature of the molten iron is 1230°C. The basicity of converter slag is controlled at 3.0-3.5, and the temperature of steel discharge is based on the carbon drawing temperature. When the carbon drawing temperature is equal to the temperature of steel discharge, the steel discharge operation can be carried out. The slag blocking method of tapping adopts a sliding plate to block slag, a...

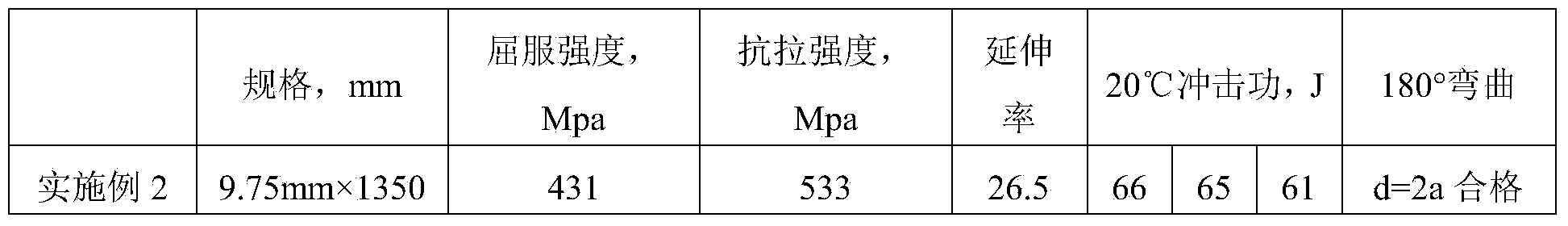

Embodiment 2

[0036] 1. The chemical composition percentage of steel is as follows:

[0037] C: 0.17%, Si: 0.18%, Mn: 0.52%, P: ≤0.017%, S: ≤0.006%, Ti: 0.036%, and the rest is Fe element and unavoidable impurities.

[0038] 2. The production process of Q345B low-alloy hot-rolled coil, taking the specification of 9.75mm×1350mm as an example:

[0039] (1) Production process

[0040] KR hot metal pretreatment-BOF-LF-CC-slab heating-rough rolling-finish rolling-coiling;

[0041] (2) Preparation process

[0042] KR molten iron pretreatment controls the sulfur content of the molten iron below 0.010%, and the temperature of the molten iron is 1239°C. The basicity of converter slag is controlled at 3.0-3.5, and the temperature of steel discharge is based on the carbon drawing temperature. When the carbon drawing temperature is equal to the temperature of steel discharge, the steel discharge operation can be carried out. The slag blocking method of tapping adopts a sliding plate to block slag, a...

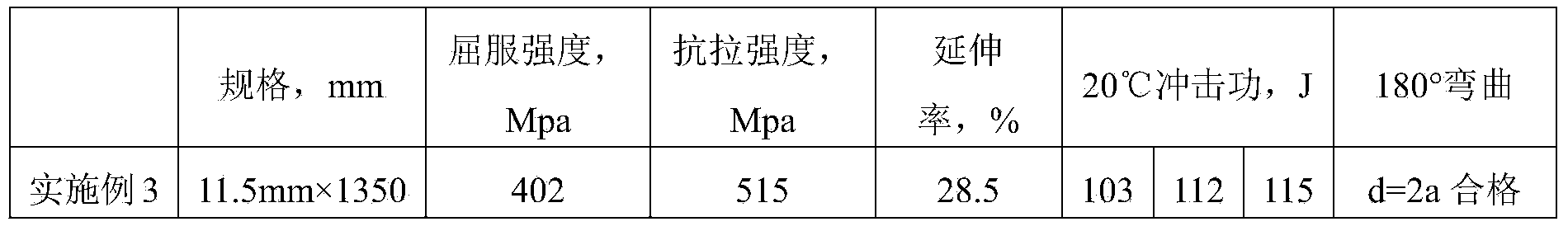

Embodiment 3

[0047] 1. The chemical composition percentage of steel is as follows:

[0048]C: 0.19%, Si: 0.14%, Mn: 0.54%, P: ≤0.015%, S: ≤0.005%, Ti: 0.033%, and the rest is Fe element and unavoidable impurities.

[0049] 2. The production process of Q345B low-alloy hot-rolled coil, taking the specification of 11.5mm×1350mm as an example:

[0050] (1) Production process

[0051] KR hot metal pretreatment-BOF-LF-CC-slab heating-rough rolling-finish rolling-coiling;

[0052] (2) Preparation process

[0053] KR molten iron pretreatment controls the sulfur content of molten iron below 0.010%, and the temperature of molten iron is 1245°C. The basicity of converter slag is controlled at 3.0-3.5, and the temperature of steel discharge is based on the carbon drawing temperature. When the carbon drawing temperature is equal to the temperature of steel discharge, the steel discharge operation can be carried out. The slag blocking method of tapping adopts a sliding plate to block slag, and the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com