Low-speed diesel-engine frame guide-board reception cutter processing method

A processing method and diesel engine technology, applied in metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve the problems of inability to process the guide plate at one time, the finish of the knife joint cannot be achieved, and the size is out of tolerance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

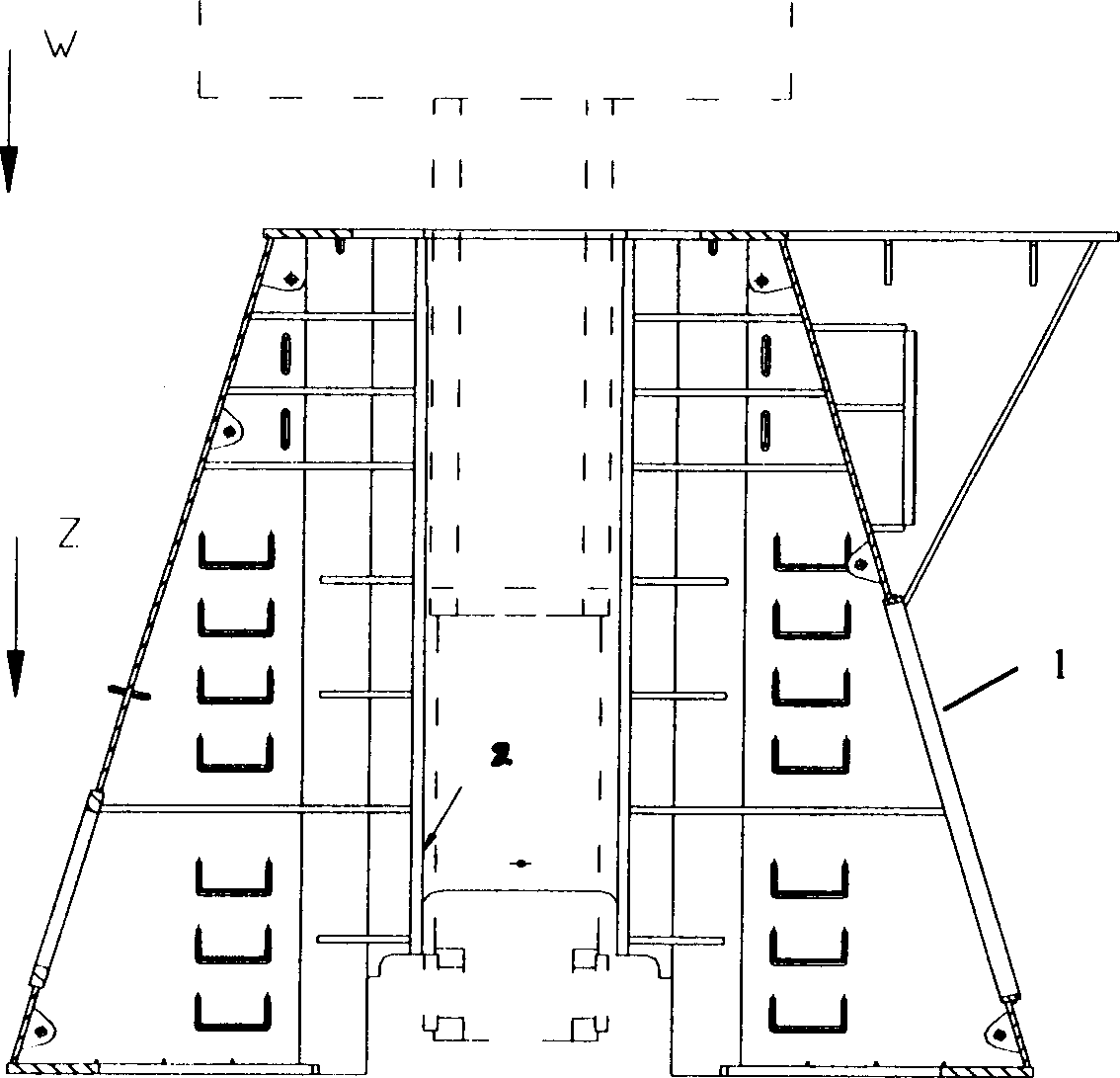

[0028] see figure 2 , Figure 4, Figure 5, Figure 6 and Figure 7. The low-speed diesel engine frame guide plate receiving knife processing method of the present invention is characterized in that the method adopts a dragon milling CNC machine tool and processes according to the following steps:

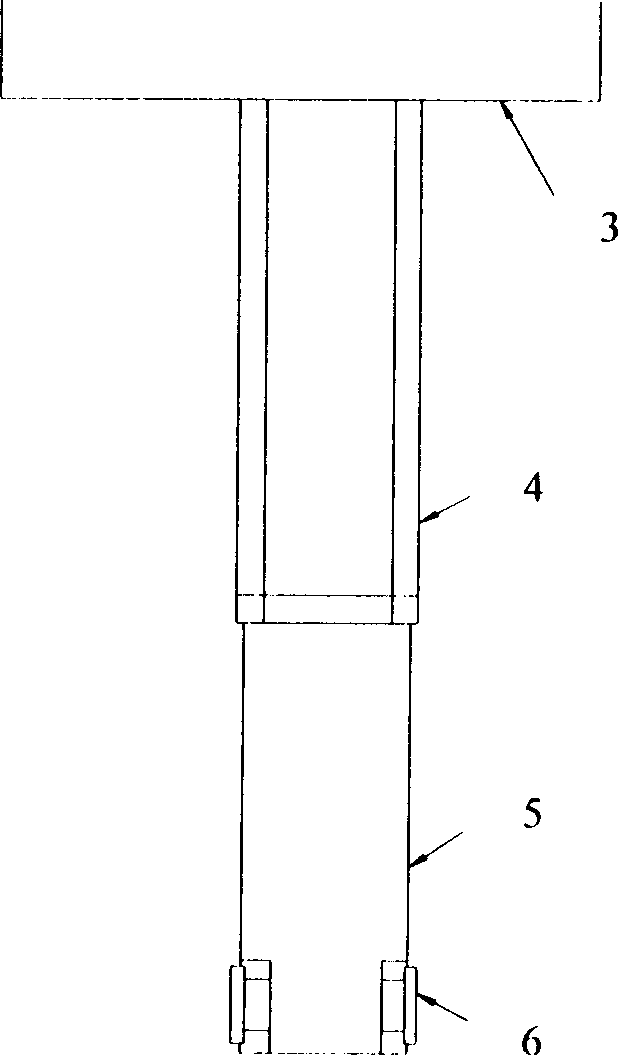

[0029] ① Put the frame 1 into place, and install the guide plate attachment 5 at the lower end of the ram 4 of the dragon milling machine, such as figure 2 As shown, the beam 3 and the ram 4 of the dragon milling machine drive the guide plate attachment 5 and its cutter head 6 to complete the rough machining and semi-finishing of the lower half of the frame 1 guide plate surface 2 from top to bottom;

[0030] ②During finishing machining, the cutter head 6 of the guide plate attachment 5 processes the guide plate to the middle position from top to bottom. When the stroke of the ram 4 is 400mm, the beam 3 and the ram 4 drive the guide plate attachment 5 and its cutter head 6 to gradua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com