Neutralization theatment method for solid residue in waste chemical weapon

A technology for solid residues and chemical weapons, which is applied in the field of neutralization and treatment of solid residues attached to discarded chemical weapon shell casings, and can solve problems such as troublesome procedures, low efficiency, and insoluble properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

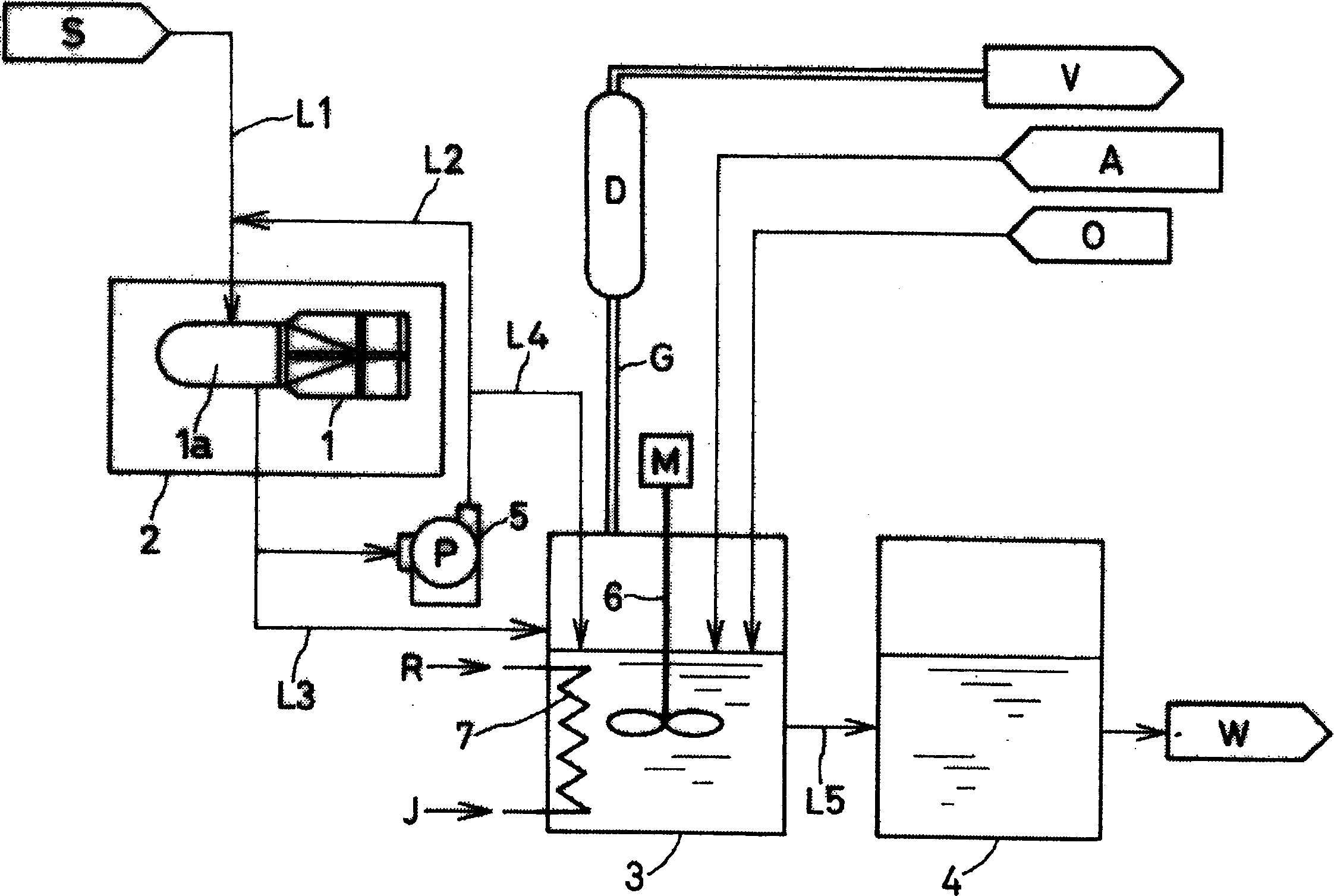

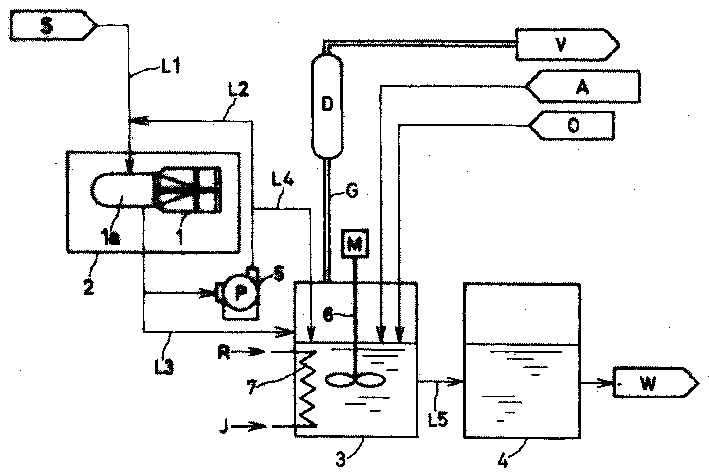

[0033] figure 1 To represent the process flow diagram of embodiment 1 of the present invention. figure 1 Among them, 1 is a chemical bomb, 2 is a dismantling machine installed in the dismantling room for dismantling and disposing of the chemical bomb 1, 3 is a reaction tank for the solution solution after the residue (solid residue) is dissolved by hydrolysis and oxidation treatment, and 4 is A treatment liquid storage tank for storing the above-mentioned treated liquid.

[0034] First, fix the chemical bomb 1, use a dismantling machine to drill a hole in its case 1a, then insert a nozzle into it, cut off the explosive part mechanically, separate the explosive part and the case, pass through the nozzle, and supply the above-mentioned solution to the solvent supply pipe L1. Organic solvents S such as MIBK are circulated through the solvent circulation pipe L2 using the pump 5, thereby washing and dissolving the residue remaining in the cartridge case. Washing and dissolving w...

Embodiment 2

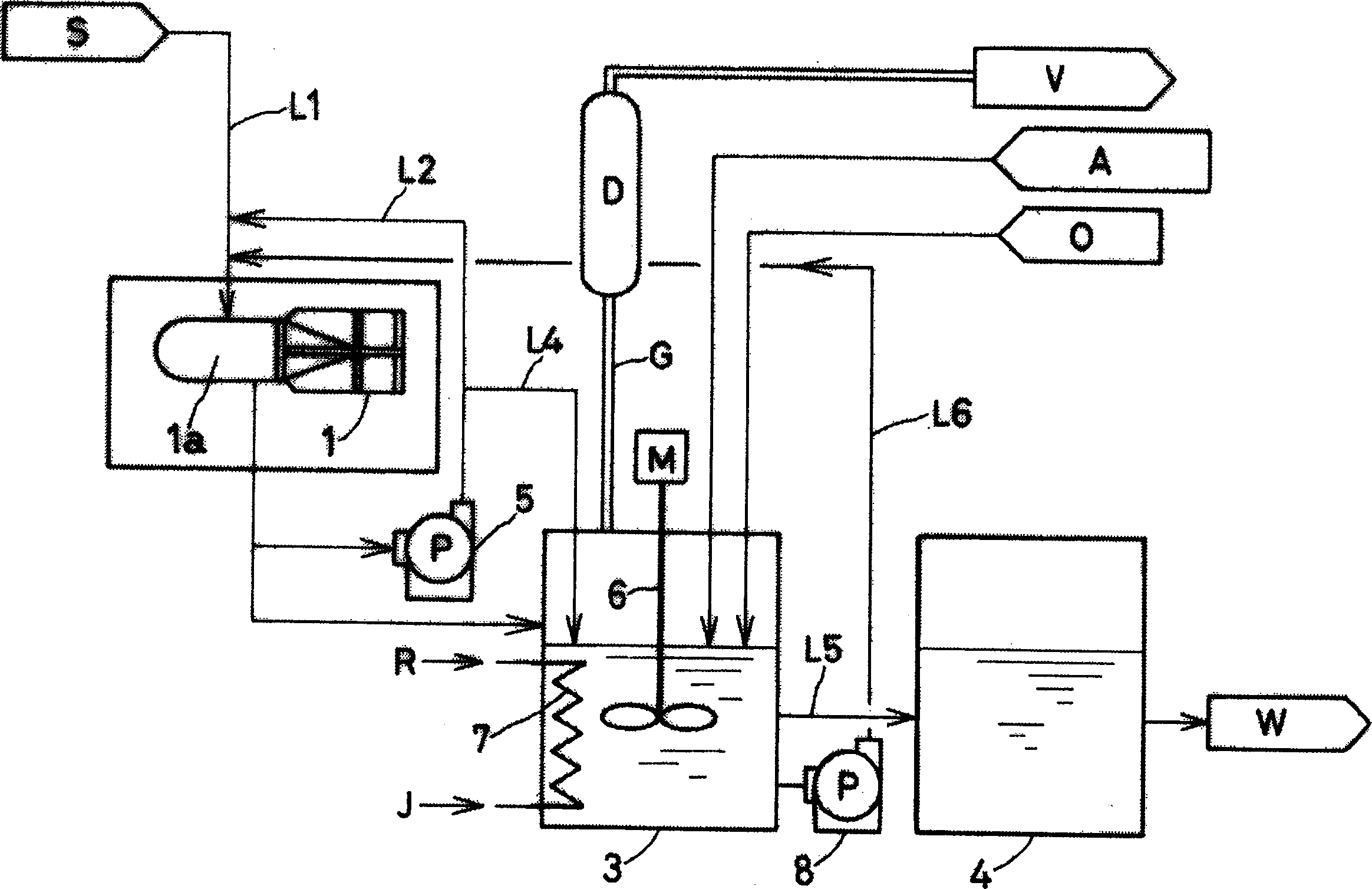

[0041] Another process embodiment of the present invention is described below. figure 2 It is a process flow diagram representing Embodiment 2 of the present invention. In this embodiment, the description of the parts that overlap with the above-mentioned embodiment 1 is omitted, and the different parts are mainly explained.

[0042] First, in the same manner as in Example 1, the above-mentioned organic solvent S such as MIBK, etc. are supplied to the solvent supply line L1 through the nozzle inserted after the cartridge case 1a of the chemical bomb 1 is opened, and the pump 5 is used to circulate them through the solvent circulation line L2. , thereby washing and dissolving the residue left in the cartridge case by the treatment (1st wash and treatment).

[0043] Then, after dissolving and removing a certain amount of residue through the first washing and dissolving, the supply and circulation of the organic solvent S is stopped, and the circulating liquid, that is, the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com